Preparation method of poly-allylamine oriented tri-dimensional (3D) platinum nano spear self-assembly body

A technology of polyallylamine and polyallylamine hydrochloride is applied in the field of preparation of three-dimensional (3D) platinum nano-pike self-assembly, which can solve the problem of reduced stability of PEMFCs, loss of Pt nanoparticles, electrocatalytic activity Reduction and other problems, to achieve the effects of excellent electrocatalytic activity and stability, excellent long-term stability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

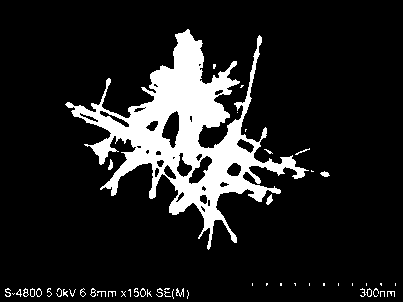

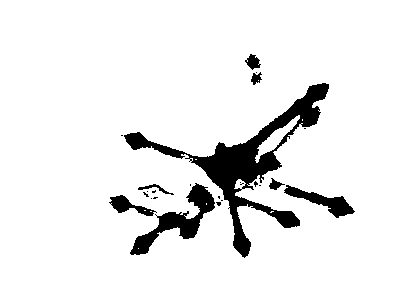

[0024] A preparation method of polyallylamine-oriented 3D platinum nano-spear self-assembly includes the following steps:

[0025] (1) Pipette 1.0 ml 0.5 M polyallylamine hydrochloride (PAH, molecular weight 150,000) solution (Note: the concentration value is calculated based on the monomer concentration) and 2.0 ml 0.025 M K 2 PtCl 4 Mix the solution with ultrasonic, adjust the pH to 0.5 with 0.1M HCl solution under stirring, and let stand for half an hour to obtain clear PAH-Pt II Complex solution.

[0026] (2) To PAH-Pt II 0.5ml HCHO (40% wt aqueous solution, the same below) was added to the complex solution, and then put into the hydrothermal reactor; the reactor was placed in a drying box at 140℃ to make PAH-Pt II The complex reacts completely with the reducing agent, metal Pt II The target product is obtained after ion reduction.

[0027] (3) After centrifugal separation and washing, the product is placed in a vacuum drying oven to dry, to obtain the platinum nano-spear self...

Embodiment 2

[0029] A preparation method of polyallylamine-oriented 3D platinum nano-spear self-assembly includes the following steps:

[0030] (1) Pipette 1.0 ml 0.5 M polyallylamine hydrochloride (PAH, molecular weight 150,000) solution (Note: the concentration value is calculated based on the monomer concentration) and 2.0 ml 0.025 M K 2 PtCl 4 Mix the solution with ultrasonic, adjust the pH to 0.2 with 0.1M HCl solution under stirring, and let it stand for half an hour to obtain clear PAH-Pt II Complex solution.

[0031] (2) To PAH-Pt II Add 0.5ml HCHO (40%) to the complex solution, and then put it into the hydrothermal reaction kettle; place the reaction kettle in the 140℃ dry box to make PAH-Pt II The complex reacts completely with the reducing agent, metal Pt II The target product is obtained after ion reduction.

[0032] (3) After centrifugal separation and washing, the product is placed in a vacuum drying oven to dry, to obtain the platinum nano-spear self-assembly.

Embodiment 3

[0034] A preparation method of polyallylamine-oriented 3D platinum nano-spear self-assembly includes the following steps:

[0035] (1) Pipette 2.0 ml 0.5 M polyallylamine hydrochloride (PAH, molecular weight 150,000) solution (Note: the concentration value is calculated based on the monomer concentration) and 2.0 ml 0.025 M K 2 PtCl 4 Mix the solution with ultrasonic, adjust the pH to 0.5 with 0.1M HCl solution under stirring, and let it stand for half an hour to obtain clear PAH-Pt II Complex solution.

[0036] (2) To PAH-Pt II Add 0.5ml HCHO (40%) to the complex solution, and then put it into the hydrothermal reaction kettle; place the reaction kettle in the 140℃ dry box to make PAH-Pt II The complex reacts completely with the reducing agent, metal Pt II The target product is obtained after ion reduction.

[0037] (3) After centrifugal separation and washing, the product is placed in a vacuum drying oven to dry, to obtain the platinum nano-spear self-assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com