Platinum-based alloy nanotube with platinum skin as well as preparation method and application of platinum-based alloy nanotube

A platinum-based alloy, nanotube technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, to achieve simple and easy preparation methods, simple preparation methods, and inhibition of Ostwalder ripening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

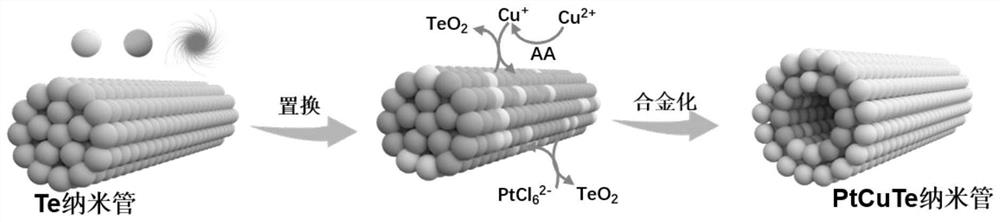

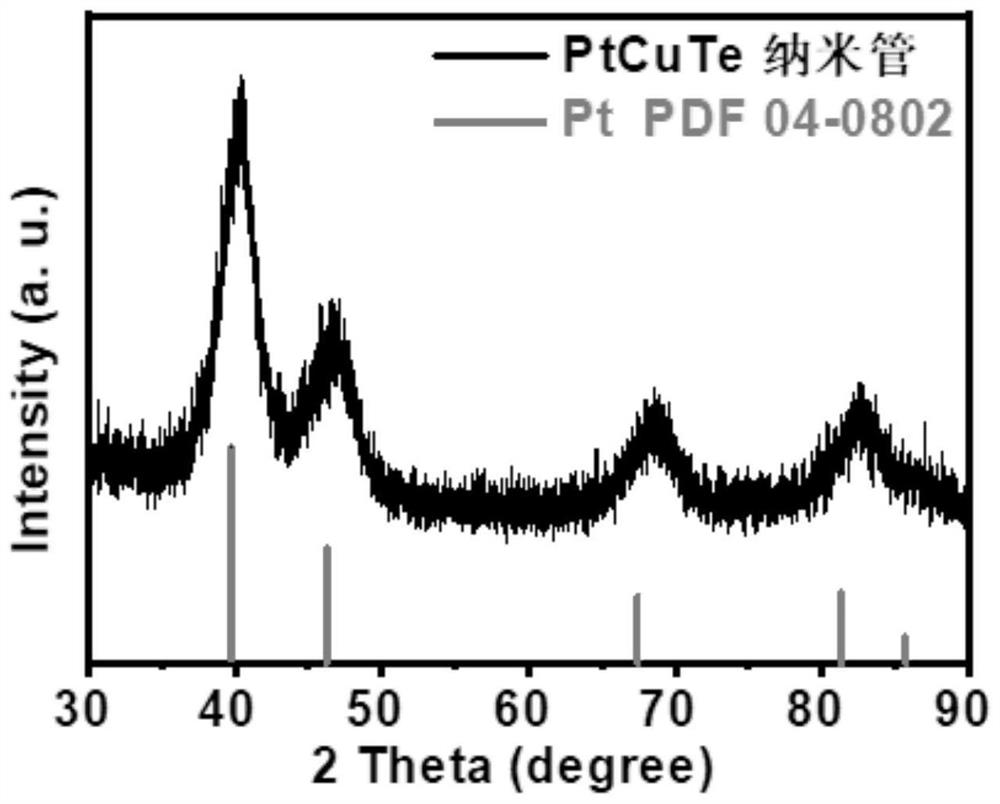

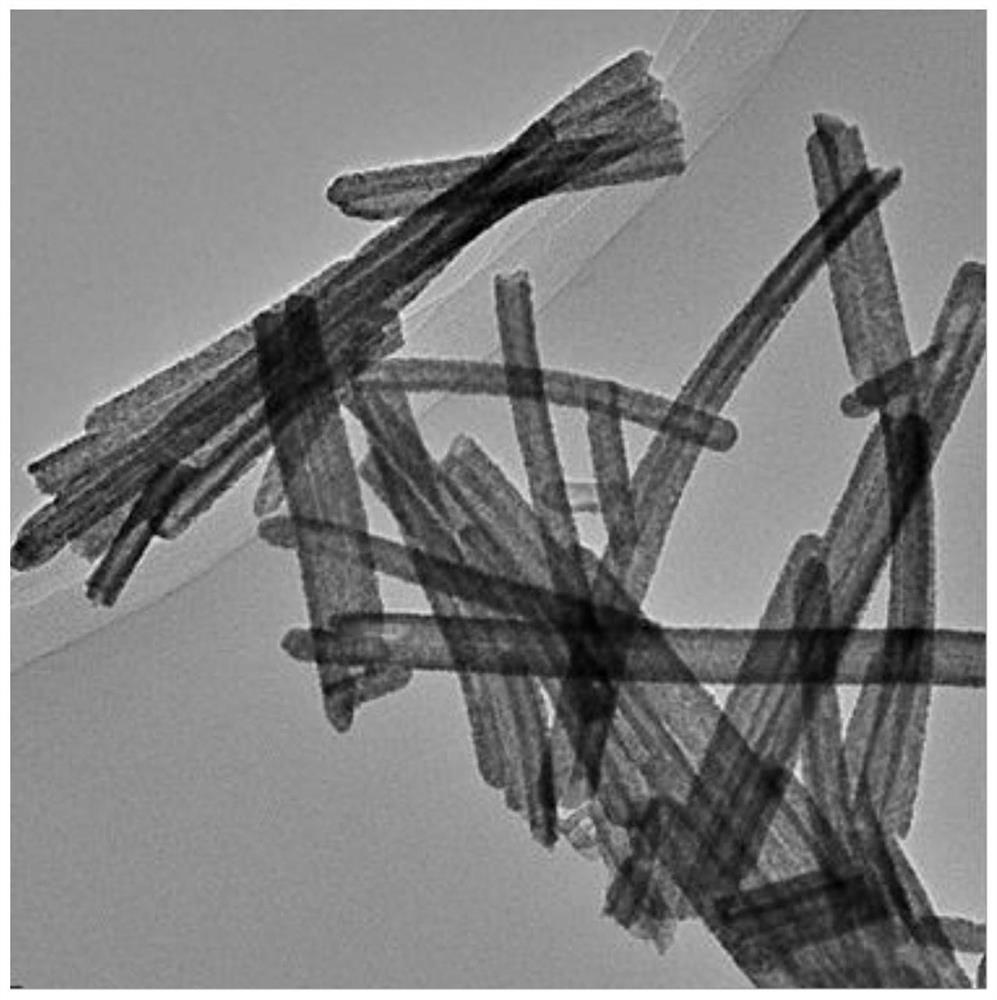

[0029] A preparation method of a platinum-based alloy nanotube catalyst with a platinum skin, comprising the following steps:

[0030] (1) Synthesis of platinum-copper-tellurium alloy nanotubes: disperse 0.2mmol tellurium nanowires, 0.5mmol ascorbic acid and 0.125g polyoxyethylene-polyoxypropylene-polyoxyethylene triblock polymer F127 in 25mL deionized water and sonicate for 1h A homogeneous suspension was obtained. To the above solution, 2 mL of chloroplatinic acid solution (0.1 M) and 1 mL of copper chloride solution (0.1 M) were sequentially added. Then reflux at 95°C for 4h in an oil bath. The reacted samples were washed three times with water / ethanol, and dried overnight at 60°C.

[0031] (2) Synthesis of platinum-copper-tellurium supported on carrier carbon: 20 mg of platinum-copper-tellurium alloy nanotubes and 15 mg of carrier carbon XC-72R were added to a mixed solution of ethanol and cyclohexane, and stirred continuously for 56 h. The obtained samples were washed ...

Embodiment 2

[0033] A preparation method of a platinum-based alloy nanotube catalyst with a platinum skin, comprising the following steps:

[0034] (1) Synthesis of platinum-copper-tellurium alloy nanotubes: disperse 0.2mmol tellurium nanowires, 0.5mmol ascorbic acid and 0.125g polyoxyethylene-polyoxypropylene-polyoxyethylene triblock polymer F127 in 25mL deionized water and sonicate for 1h A homogeneous suspension was obtained. To the above solution, 1 mL of chloroplatinic acid solution (0.1 M) and 1 mL of copper chloride solution (0.1 M) were sequentially added. Then reflux at 95°C for 4h in an oil bath. The reacted samples were washed three times with water / ethanol, and dried overnight at 60°C.

[0035] (2) Synthesis of platinum-copper-tellurium supported on carrier carbon: 20 mg of platinum-copper-tellurium alloy nanotubes and 15 mg of carrier carbon XC-72R were added to a mixed solution of ethanol and cyclohexane, and stirred continuously for 56 h. The obtained samples were washed ...

Embodiment 3

[0037] A preparation method of a platinum-based alloy nanotube catalyst with a platinum skin, comprising the following steps:

[0038] (1) Synthesis of platinum-copper-tellurium alloy nanotubes: disperse 0.2mmol tellurium nanowires, 0.5mmol ascorbic acid and 0.125g polyoxyethylene-polyoxypropylene-polyoxyethylene triblock polymer F127 in 25mL deionized water and sonicate for 1h A homogeneous suspension was obtained. To the above solution, 3 mL of chloroplatinic acid solution (0.1 M) and 1 mL of copper chloride solution (0.1 M) were sequentially added. Then reflux at 95°C for 4h in an oil bath. The reacted samples were washed three times with water / ethanol, and dried overnight at 60°C.

[0039] (2) Synthesis of platinum-copper-tellurium supported on carrier carbon: 20 mg of platinum-copper-tellurium alloy nanotubes and 15 mg of carrier carbon XC-72R were added to a mixed solution of ethanol and cyclohexane, and stirred continuously for 56 h. The obtained samples were washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com