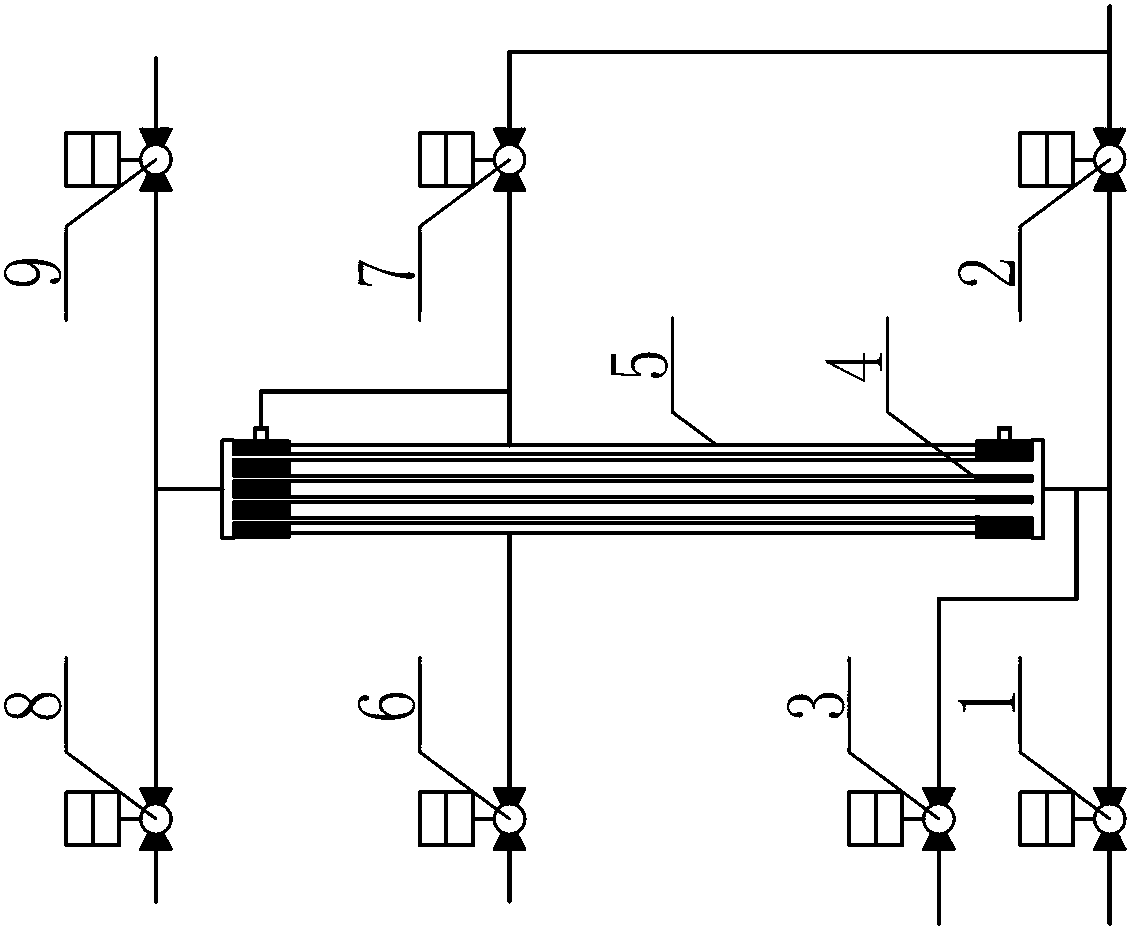

Method for realizing water treatment by using pressure type continuous membrane filtering system

A filtration system and continuous membrane technology, applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, ultrafiltration, etc., can solve the difference in aeration intensity of membrane filaments, inadequate cleaning of membrane filaments, and easy wear and tear of membrane filaments, etc. problems, achieve the effect of reducing self-water consumption, prolonging membrane cleaning cycle, and avoiding easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

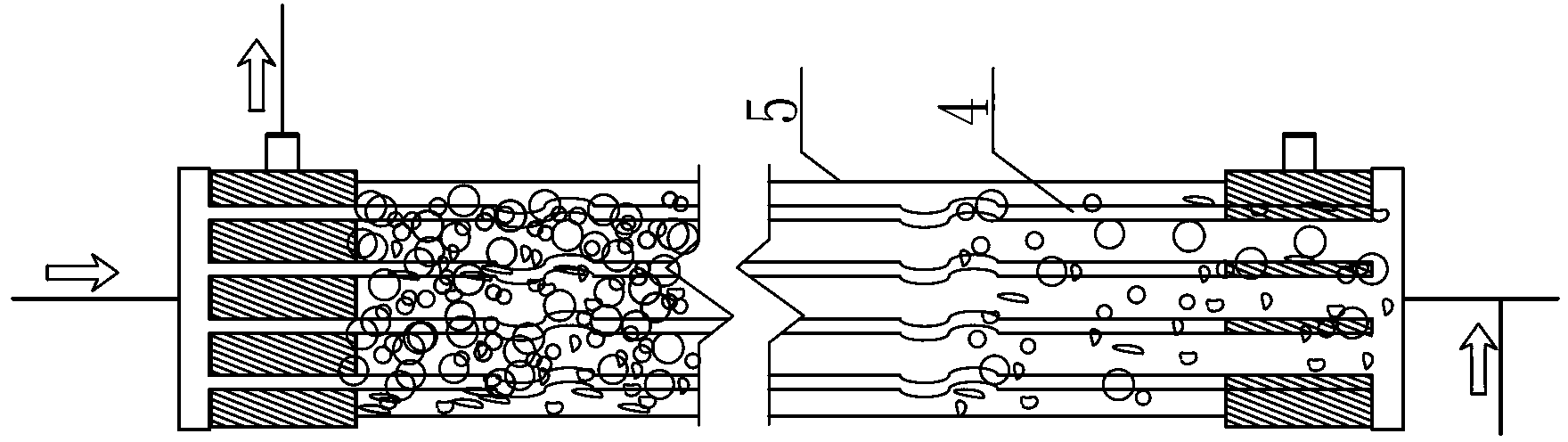

[0018] Example 1: A municipal sewage treatment plant adopts the traditional biochemical treatment process, and the effluent of the secondary sedimentation tank enters the ultrafiltration membrane system after coagulation and sedimentation, but the turbidity of the system influent water is about 1.0 NTU. Before the improvement, the water production stage of the system was 20 minutes, and the constant flow water production flux was 2.0m 3 / branch.h; backwash volume of small flow in air-water double washing stage is 0.3m 3 / branch.h, the time is 30s, the large flow backwashing stage is 2.0m 3 / stick.h, the time is 30s, and the sewage discharge stage is static pressure discharge. By adjusting the parameters, the water production stage time of the improved system is 20 minutes, and the constant flow water production flux is 2.0m 3 / branch.h; the concentrated raw water discharge stage is static pressure discharge to the bottom; the air-water double washing stage has a small fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com