Treatment system and treatment method for coal-to-liquid wastewater

A treatment system, coal-to-oil technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve difficult-to-treat industrial wastewater, coal-to-oil wastewater with complex components, etc. , to achieve the effect of improving processing capacity and environmental protection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

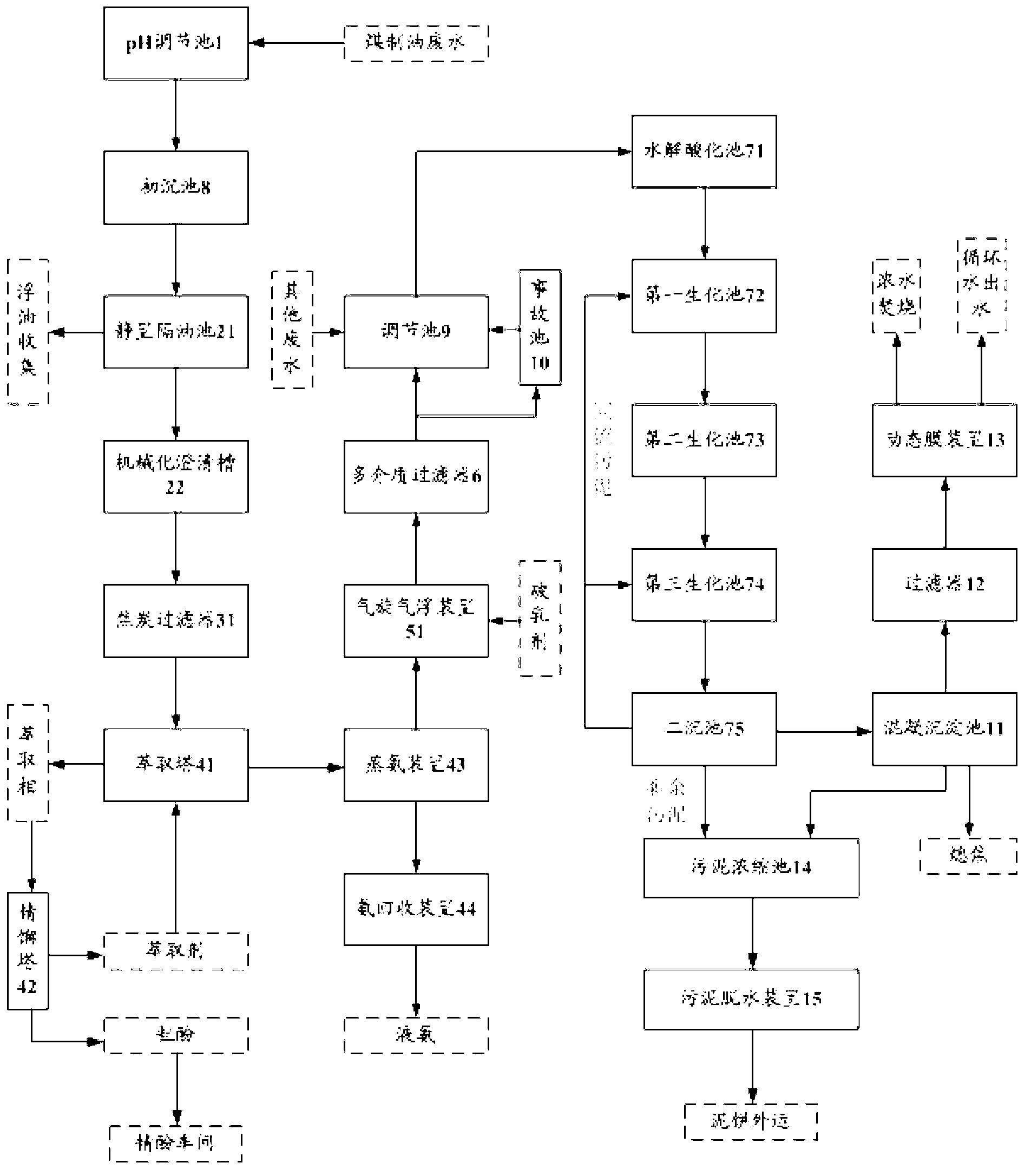

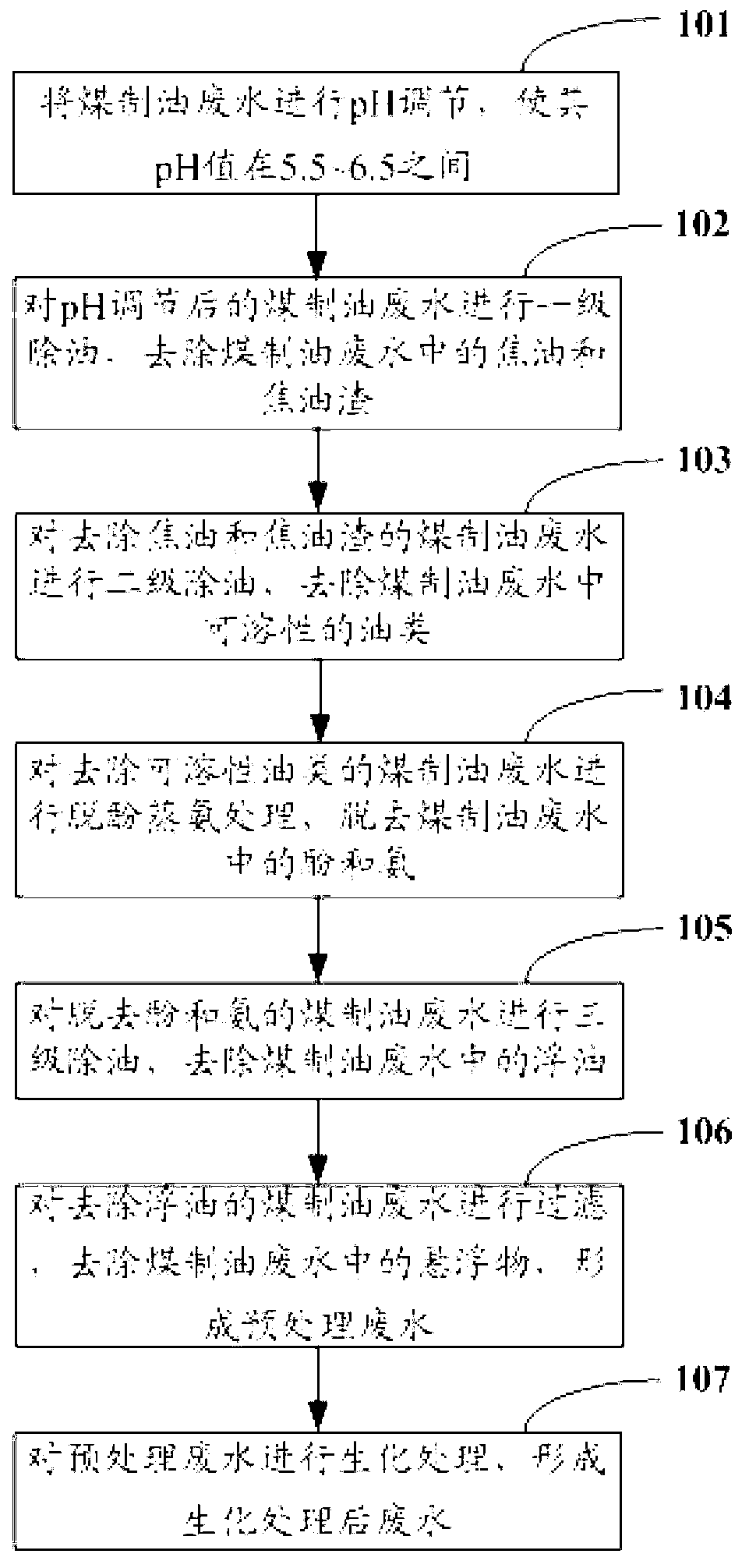

[0049] In order to improve the ability of biochemically treating coal-to-oil wastewater, the invention provides a treatment system and method for coal-to-oil wastewater. In this technical scheme, the coal-to-oil wastewater is subjected to pH adjustment, first-stage oil removal, second-stage oil removal, dephenolization and ammonia distillation, third-stage oil removal, and filtration to form pretreated wastewater in sequence. Pollutants such as tar, ammonia, phenol, and oil slick in the coal-to-oil wastewater have been removed, so it can be treated by biochemical treatment. Therefore, a method for biochemical treatment of coal tar wastewater is provided, which improves the coal Biochemical treatment capacity of oil wastewater. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail.

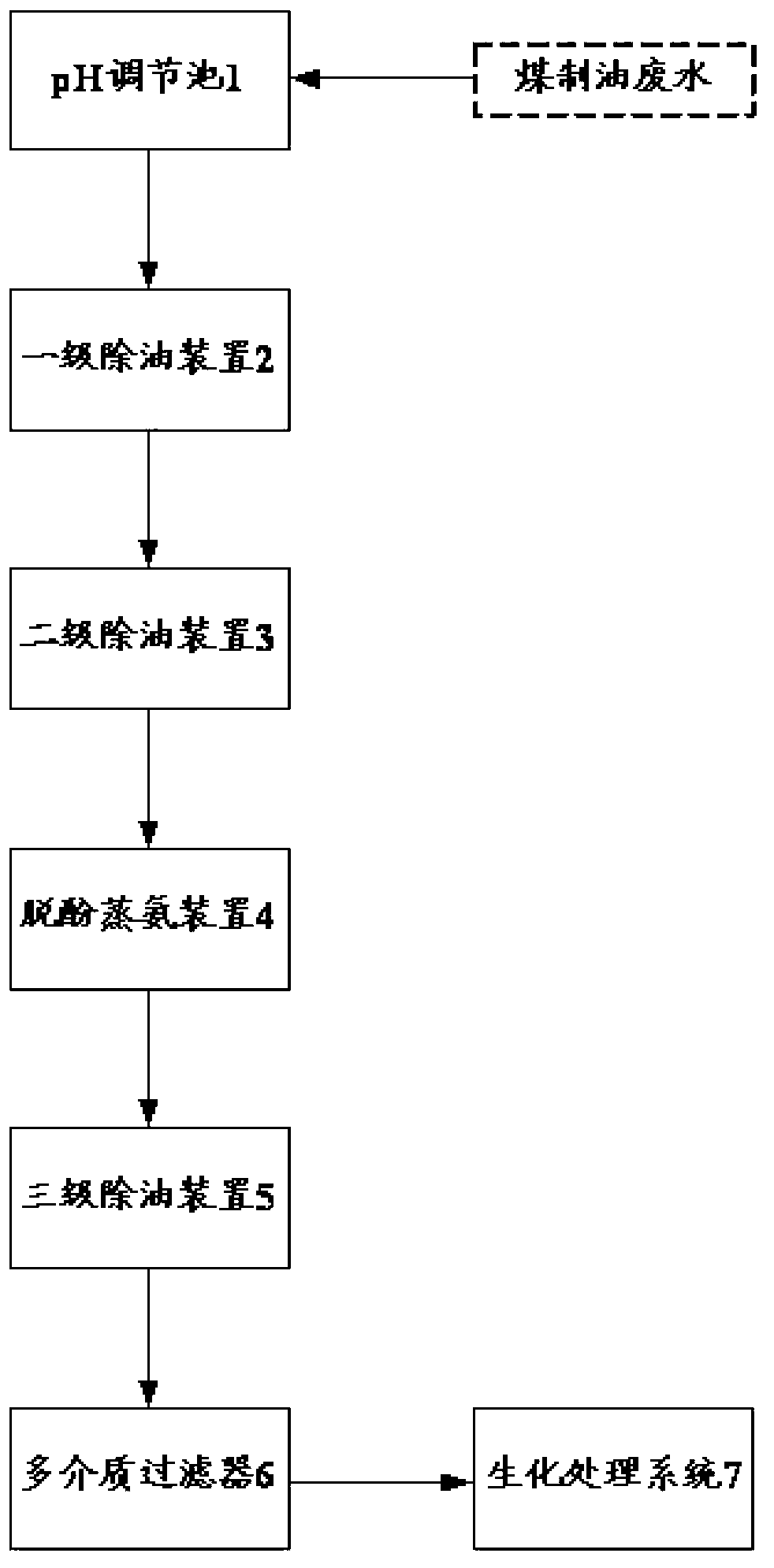

[0050] like figure 1 As shown, the process schematic diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com