Preparation method and equipment of Ge-Sb-Se systematic infrared glass

A technology of ge-sb-se and infrared glass, which is applied in the field of preparation of Ge-Sb-Se system infrared glass, can solve problems affecting the imaging quality and stability of thermal imaging systems, fluctuations in the composition and performance of chalcogenide glass products, and difficult operation etc. to achieve the effects of reducing the difficulty of volatilization control, improving optical uniformity, and ensuring yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

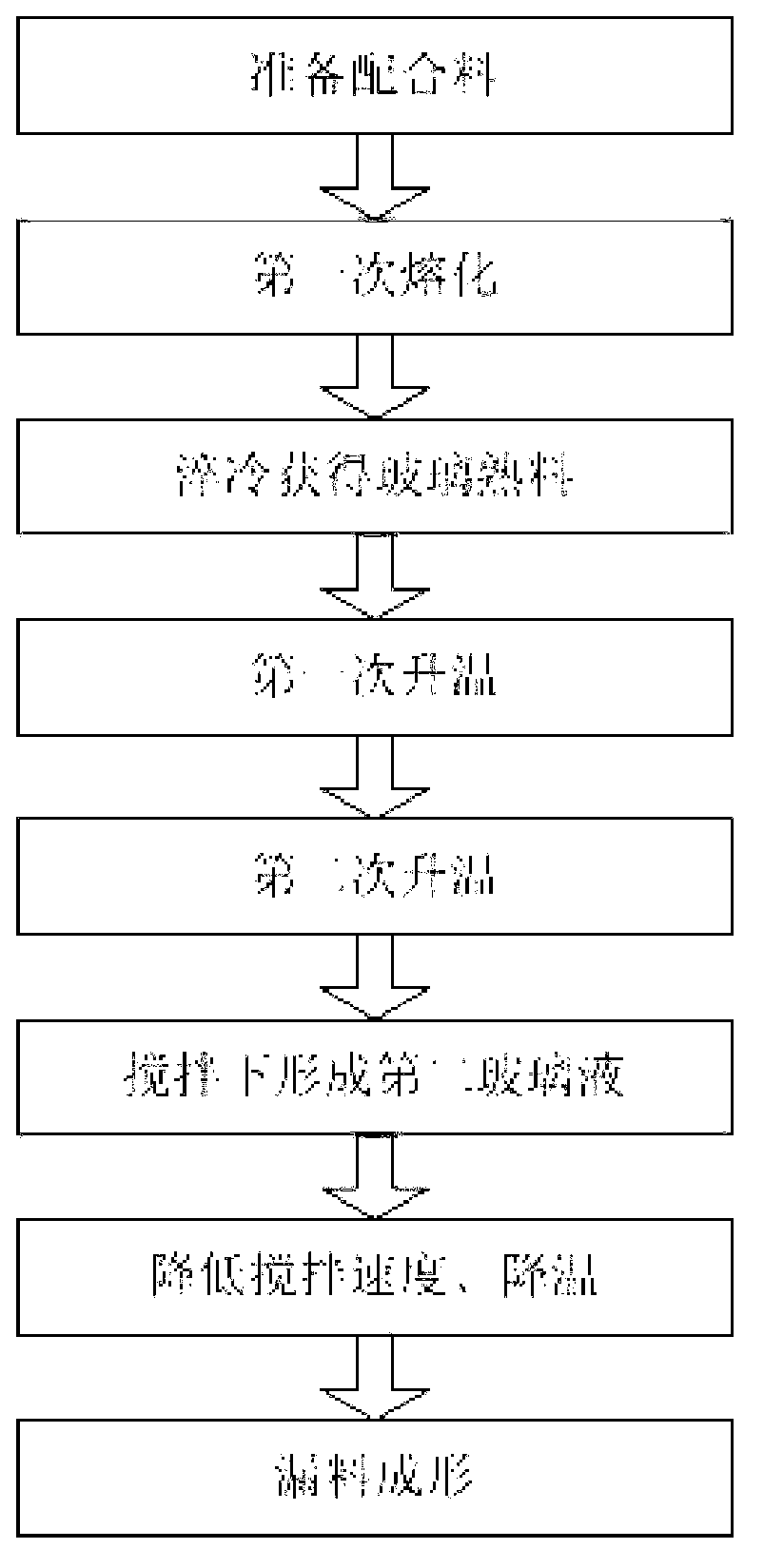

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: preparation molecular composition is Ge 15 Sb 5 Se 80 chalcogenide infrared glass

[0034] (1) Preparation of batch materials: In this example, a total of 2000g batch materials were prepared, and 500g batch materials were prepared in four times each time; Ge, Se, Sb and Al with a purity of 5N grade (99.999% purity) were used; according to the atomic ratio Ge 15 Sb 5 Se 80 Carry out calculation and weighing, mix it to make 500g of batch material, then add 50ppm of oxygen scavenger Al based on the total amount of batch material, and put it into a Φ50 quartz ampoule; repeat the weighing of 3 parts of batch material according to the above steps , into three Φ50 quartz ampoules; put the above four quartz ampoules at 300°C, 10 -3 Vacuum baking under Pa condition for 3 hours to further remove impurities adsorbed on the surface of raw materials.

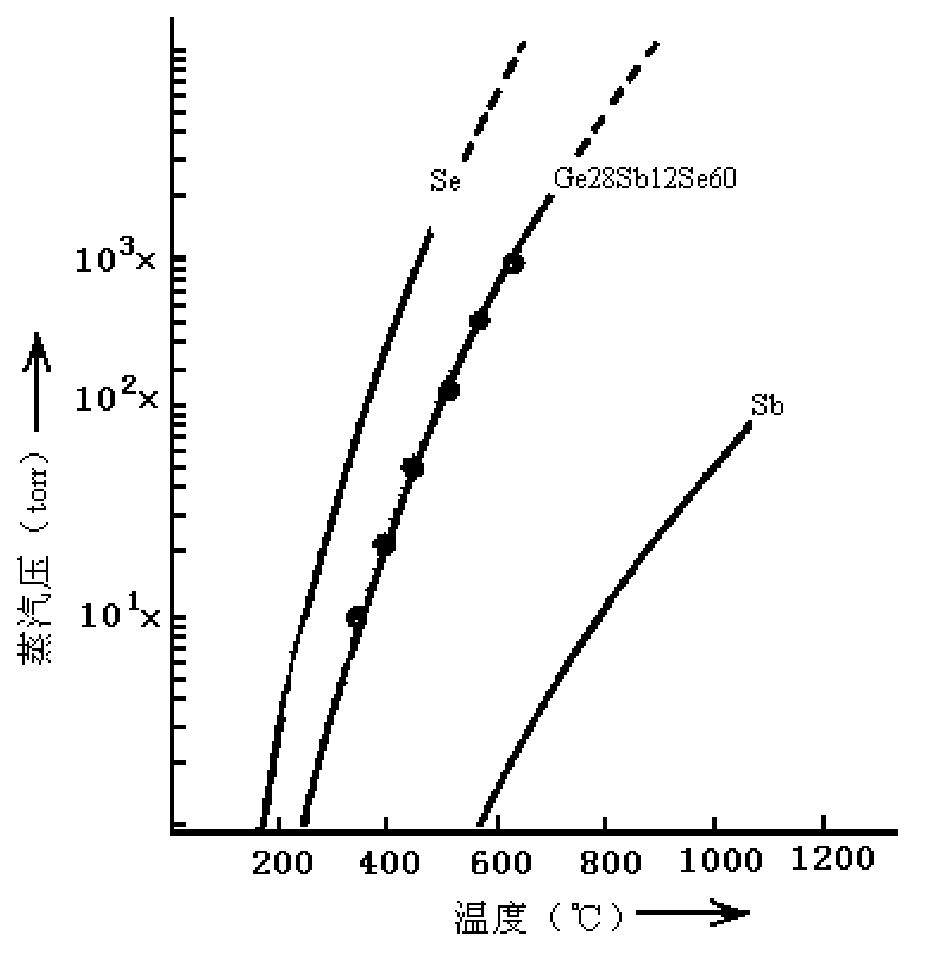

[0035] (2) Melting for the first time: Vacuumize the above-mentioned quartz ampoule containing the batch materi...

Embodiment 2

[0038] Embodiment 2: preparation molecular composition is Ge 35 Sb 10 Se 55 sulfur infrared glass

[0039] (1) Preparation of batch materials: 2000g of batch materials are prepared in this example, using Ge, Se, Sb and Al with a purity of 5N grade (99.999% purity); 35 Sb 10 Se 55 Carry out calculation and weighing, mix it to make a batch, then add 80ppm of oxygen scavenger Al based on the total amount of the batch, and put it into a Φ100 quartz ampoule; put the above quartz ampoule at 320 ° C, 10 -3 Vacuum baking under Pa condition for 8 hours to further remove impurities adsorbed on the surface of raw materials.

[0040] (2) Melting for the first time: Vacuumize the above-mentioned quartz ampoule containing the batch material and oxygen scavenger to 10 -3 Seal after Pa. Put the fused-sealed quartz ampoule in a swing furnace, heat up to 560°C at a rate of 8°C / min, keep at this temperature for 3 hours to fully react Se and Sb, and then heat up to 900°C at a rate of 3°C / m...

Embodiment 3

[0042] Embodiment 3: preparation molecular composition is Ge 25 Sb 25 Se 50 sulfur infrared glass

[0043] (1) (1) Prepare batch materials: 2000g batch materials are prepared in this example, using Ge, Se, Sb and Al with a purity of 5N grade (99.999% purity); 25 Sb 25 Se 50 Carry out calculation and weighing, mix it to make a batch, then add 100ppm of oxygen scavenger Al based on the total amount of the batch, and put it into a Φ100 quartz ampoule; put the above quartz ampoule at 350 ° C, 10 -3 Vacuum baking under Pa conditions for 10 hours to further remove impurities adsorbed on the surface of raw materials.

[0044] (2) Melting for the first time: Vacuumize the above-mentioned quartz ampoule containing the batch material and oxygen scavenger to 10 -3 Seal after Pa. Put the fused-sealed 4 quartz ampoules in a swing furnace, heat up to 580°C at a rate of 10°C / min, keep at this temperature for 5 hours to fully react Se and Sb, and then heat up at a rate of 4°C / min to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com