Production method of electrolytic manganese metal

A technology of electrolytic manganese metal and production method, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve problems such as not being applied in industry, achieve the effects of reducing procurement and transportation costs, solving raw material dependence, and simplifying the impurity removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

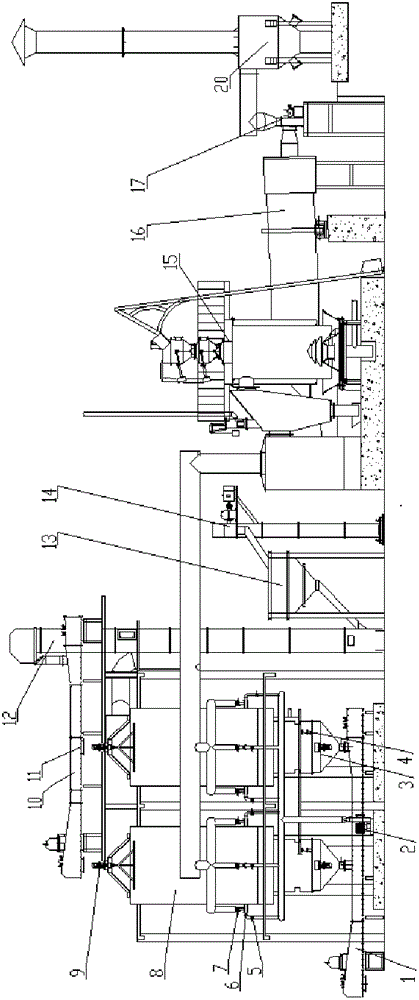

[0022] figure 1 It is a structural schematic diagram of the production device of manganese monoxide ore powder of the present invention.

[0023] See figure 1 The production device of manganese monoxide ore powder provided by the present invention comprises a vertical reduction furnace 8, the top of the reduction furnace 8 is provided with an automatic distributing machine 9 and a feeding scraper 10, and the bottom of the reduction furnace 8 is provided with A heat medium gas burner 6 and a combustion-supporting blower 2, a cooling water tank 3 and a discharge scraper 1 are provided at the bottom of the reduction furnace 8. The number of the reduction furnaces 8 may be multiple, and the multiple reduction furnaces 8 are arranged side by side.

[0024] In the production device of manganese monoxide ore powder provided by the present invention, the fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com