Curve approximation control method for cheese dyeing process

A technology of dyeing process and control method, which is applied in the field of curve approximation control of cheese dyeing process, and can solve problems such as large fluctuations in product quality, cutting corners, and broken yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

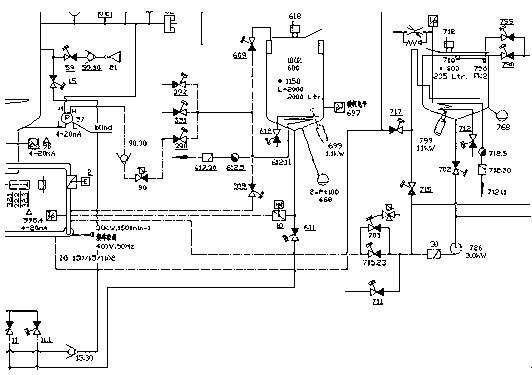

[0024] Embodiment 1 Dyeing process of a piece of light-colored cotton yarn

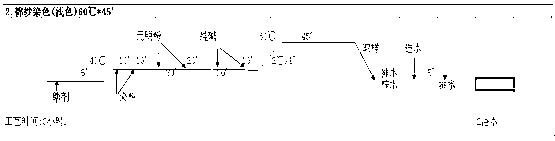

[0025] figure 2 It is the dyeing process curve for light-colored cotton yarn. This dyeing process requires two temperature rises, adding dyes, sodium sulfate, additives, soda ash, etc. once each. The dyeing temperature is 60°C, the holding time is 45 minutes, the temperature rise slope is 2°C per minute from 40°C to 60°C, and the quantitative addition of dyes The time is 10 minutes.

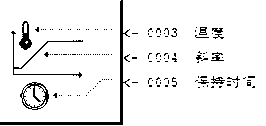

[0026] Set the feeding curve as attached image 3 As shown, the main curve setting parameters are realized by quantitative time and increasing slope to set the curve. Among them, the quantitative time parameter requires how many minutes to empty the material tank, and the incremental slope parameter requires the increase of the slope. If the incremental slope is 0, it requires direct feeding, that is, the minimum number of units sent per unit time is a fixed value, and feeding The curve is a straight line with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com