Ultrasonic measuring device for oil film thickness

A technology of ultrasonic measurement and oil film thickness, which is applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of signal resolution reduction and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

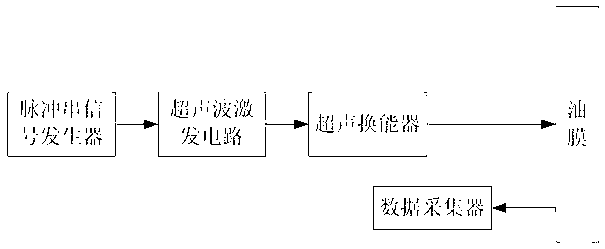

[0024] Such as figure 1 As shown, the ultrasonic measurement device for oil film thickness includes: a pulse train signal generator, an ultrasonic excitation circuit, an ultrasonic transducer, and a data collector. The pulse train signal generator transmits the high frequency pulse train signal to the ultrasonic excitation circuit. The ultrasonic excitation circuit outputs high-voltage pulses under the excitation of high-frequency pulse train signals. The ultrasonic transducer converts the high-voltage pulse into the test ultrasonic wave, which is output to the oil film. The data collector collects the reflected ultrasonic waves of the oil film.

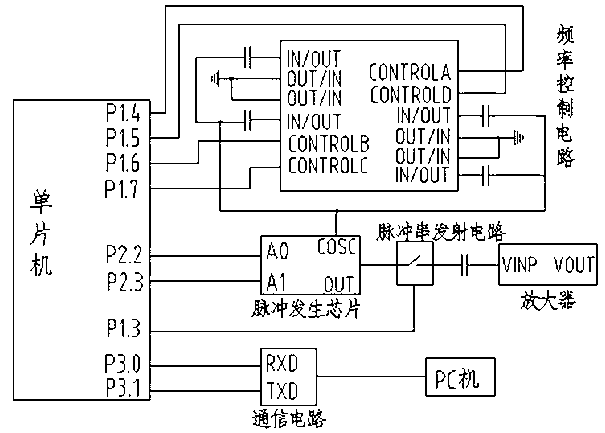

[0025] The pulse train signal generating circuit such as figure 2 As shown, it includes single-chip microcomputer, pulse generation chip MAX038, frequency control circuit, pulse train transmitting circuit, and ampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com