Method for improving storage performance of lithium cobalt oxide at high voltage and high temperature

A storage performance, high-voltage technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of material structure collapse, severe battery gas, battery gas, etc., to reduce the expansion rate, increase the charging voltage, and reduce the probability of contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

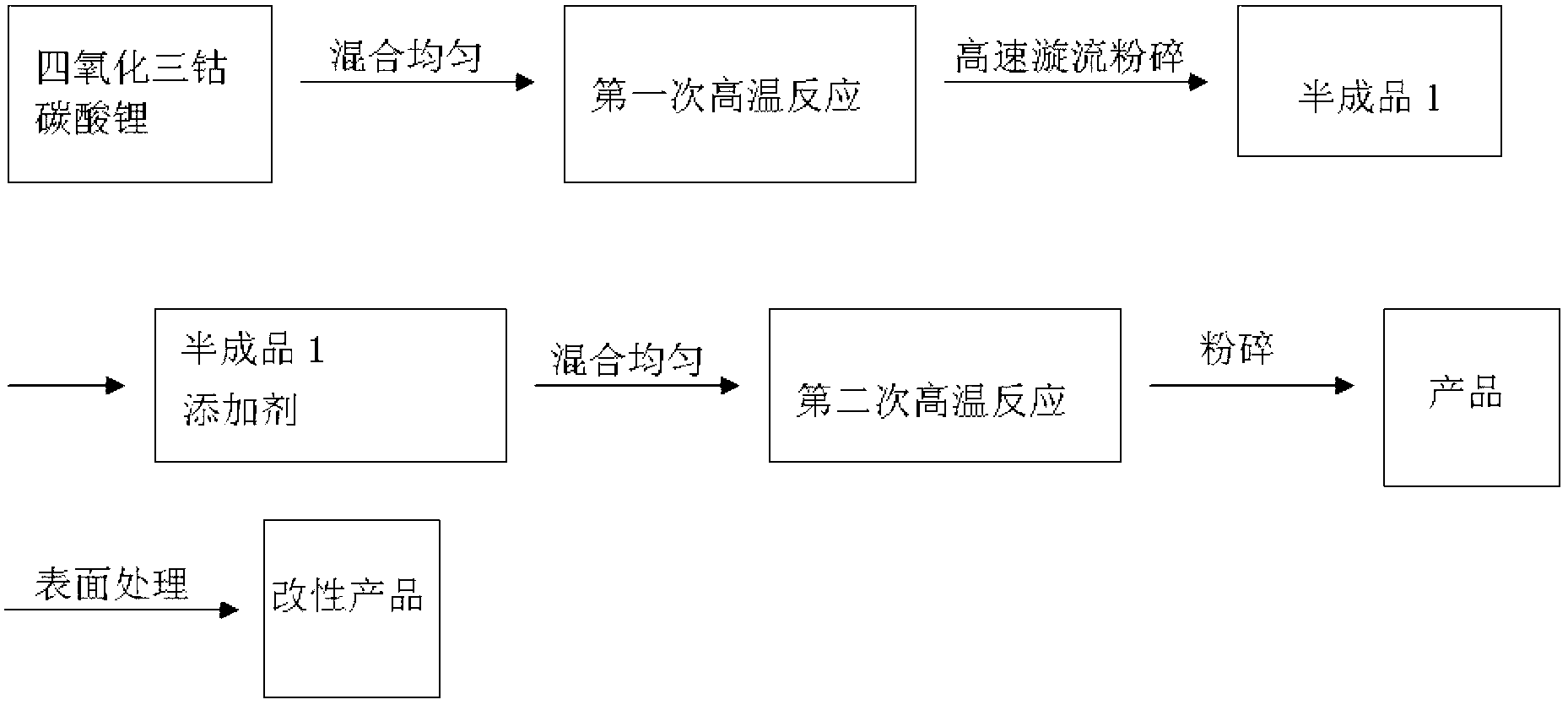

Method used

Image

Examples

Embodiment 1

[0027] The product synthesized in the comparative example was used as a raw material, and the surface treatment agent zirconia was added for surface coating treatment. The mass ratio of zirconia to the product synthesized in the comparative example was 0.2%, and the modified product was obtained by grinding for 1 hour. Median particle size D of surface treatment agent 50 No more than 5μm, the median particle size D of the modified lithium cobalt oxide product 50 10.0~20.0μm, D 100 ≤70μm.

[0028] The modified product was used as the positive electrode material to make a battery. After formation, the battery was charged to 4.4V and stored at 85°C for 8 hours. The thickness of the battery before and after storage was 4.71mm and 6.86mm, and the expansion rate of the battery was 45.6%.

Embodiment 2

[0030] The product synthesized in the comparative example was used as a raw material, and the surface treatment agent nano-aluminum powder was added for surface coating treatment. The mass ratio of the nano-aluminum powder to the product synthesized in the comparative example was 0.2%, and mixed for 1 hour to obtain a modified product. The median particle size D of the modified lithium cobalt oxide product 5010.0~20.0μm, D 100 ≤70μm.

[0031] The modified product was used as the positive electrode material to make a battery. After formation, the battery was charged to 4.4V and stored at 85°C for 8 hours. The thickness of the battery before and after storage was 4.76mm and 6.00mm, and the expansion rate of the battery was 26.1%.

Embodiment 3

[0033] With the product synthesized in the comparative example as raw material, add surface treatment agent nano-aluminum powder, it is carried out surface coating treatment, the mass ratio of nano-aluminum powder and the product synthesized in the comparative example is 0.2%, shear in the vibrator After 30 minutes, the modified product was obtained. The median particle size D of the modified lithium cobalt oxide product 50 10.0~20.0μm, D 100 ≤70μm.

[0034] The modified product was used as the positive electrode material to make a battery. After formation, the battery was charged to 4.4V and stored at 85°C for 8 hours. The thickness of the battery before and after storage was 4.80mm and 5.45mm, and the expansion rate of the battery was 13.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com