Process for producing hot-pressed member

一种制造方法、部件的技术,应用在制造工具、化学仪器和方法、叠加层的镀覆等方向,能够解决冲压成型性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

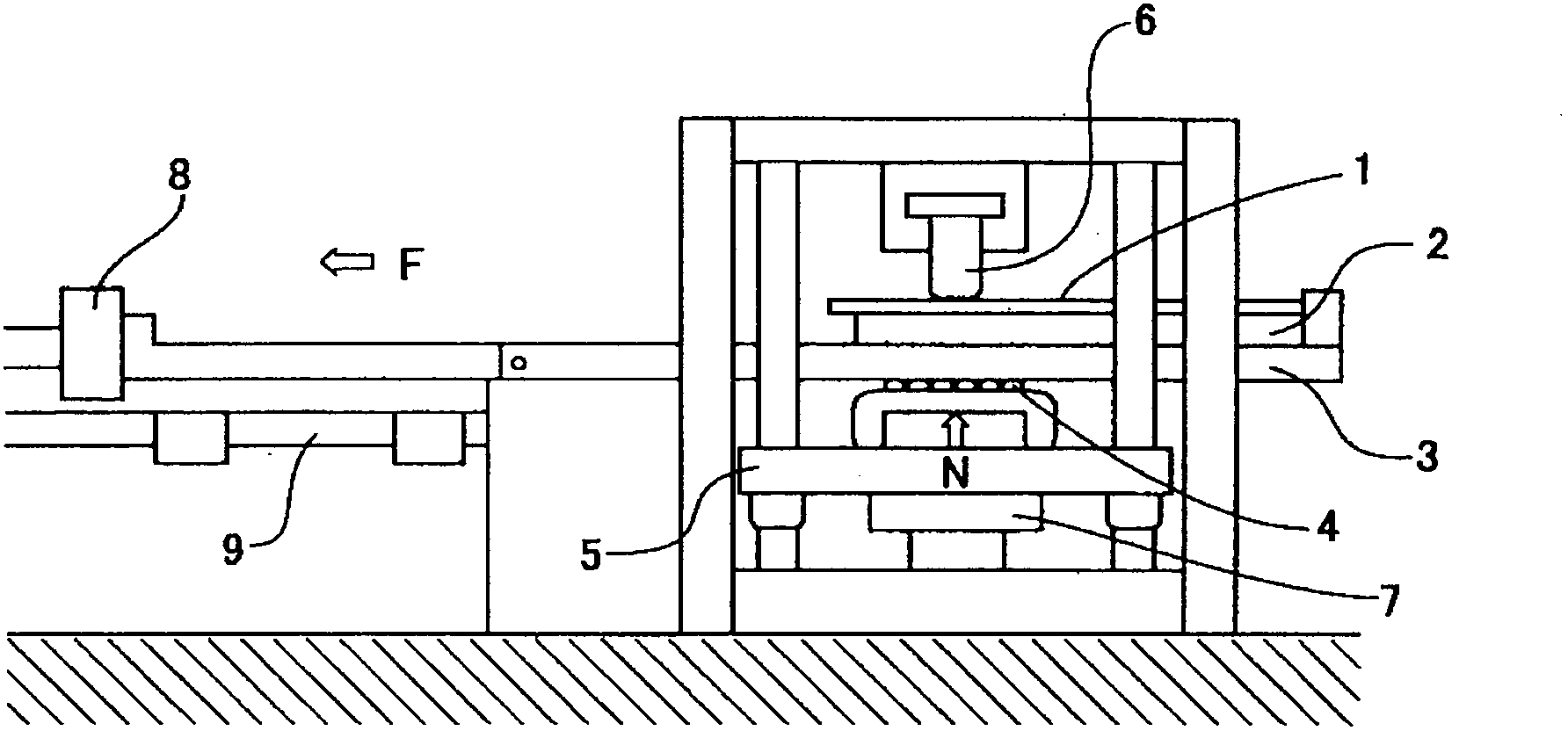

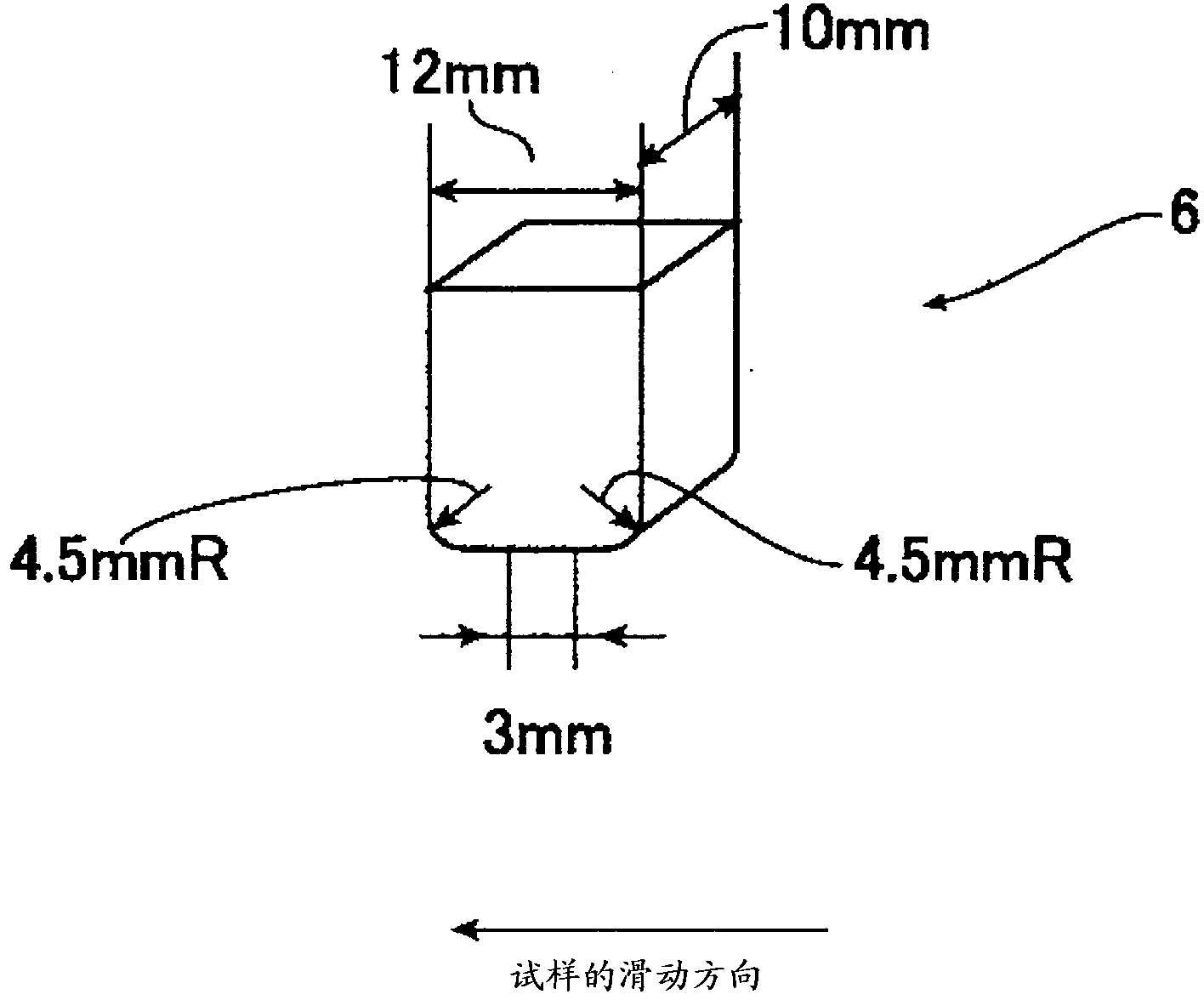

Method used

Image

Examples

Embodiment 1

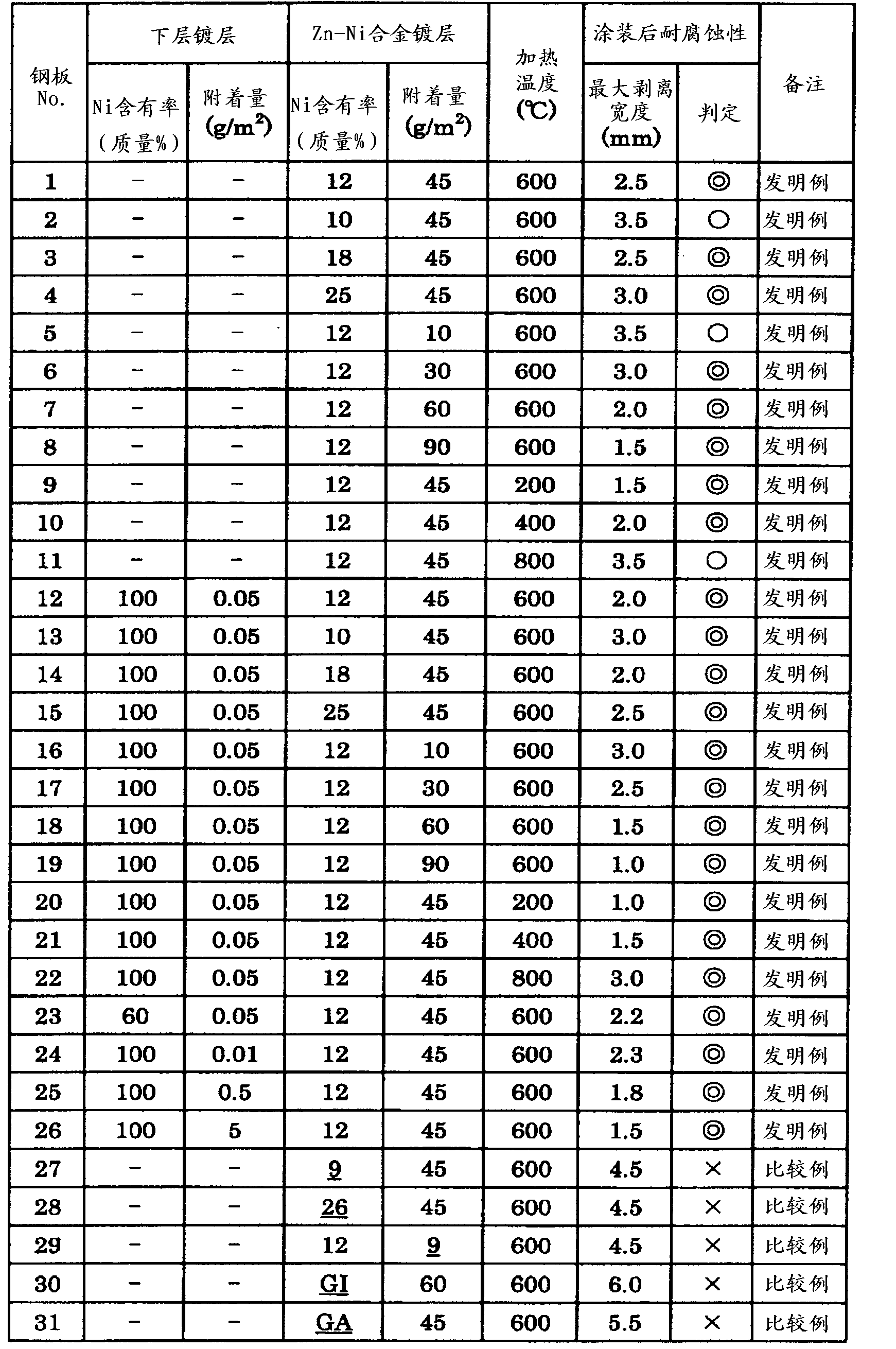

[0076] As the base steel sheet, a hot-rolled steel sheet with a thickness of 2.3 mm having the following composition, that is, containing C: 0.10%, Si: 0.02%, Mn: 1.2%, P: 0.01%, and S: 0.003% by mass % , Al: 0.03%, N: 0.003%, Ti: 0.12%, Mo: 0.22%, and the remainder is a hot-rolled steel sheet composed of Fe and unavoidable impurities. Change the current density to 5-100A / dm in a plating bath containing 200g / L nickel sulfate hexahydrate and 10-100g / L zinc sulfate heptahydrate at a pH of 1.5 and a temperature of 50°C 2 , the surface of the hot-rolled steel sheet is subjected to electroplating treatment to form Zn—Ni alloy plating layers with different Ni content and deposition amount. In addition, before the above-mentioned Zn-Ni alloy coating is formed, in a plating bath containing 200g / L of nickel sulfate hexahydrate and 0-50g / L of zinc sulfate heptahydrate at a pH of 3.0 and a temperature of 50°C, the The current density changes from 5 to 100A / dm 2 , Part of the steel plat...

Embodiment 2

[0087] On the surface of the same base steel sheet as in Example 1, Zn—Ni alloy plating layers having different Ni contents and deposition amounts were formed by the same method as in Example 1. In addition, in some steel sheets, by the same method as in Example 1, prior to the formation of the above-mentioned Zn-Ni alloy plating layer, an underlayer plating layer having a different Ni content and deposition amount was formed. Thereafter, a compound containing one of Si-containing compounds, Ti-containing compounds, Al-containing compounds, Zr-containing compounds, and Si and Zr-containing compounds shown below is coated on the Zn-Ni alloy plating layer, and the remainder is composed of a solvent. composition (solid content ratio 15% by mass), drying is carried out under the condition that the steel plate reaches a temperature of 140°C, and Si-containing compound layers, Ti-containing compound layers, and Al-containing compound layers with different thicknesses shown in Tables ...

Embodiment 3

[0111] On the surface of the same base steel sheet as in Example 1, the lower layer plating layer shown in Table 4 and the Zn—Ni alloy plating layer were sequentially formed in the same manner as in Example 1. Thereafter, on the Zn-Ni alloy plating layer, the inorganic solid lubricant shown in Table 4 was coated in the same method as in Example 2, and the remaining After the composition (solid content ratio: 15% by mass) partially composed of a solvent was dried under the condition that the steel plate reached temperature was 140° C., the Si-containing compound layer shown in Table 4 was formed, and steel plates Nos. 1 to 17 were produced. As the inorganic solid lubricant shown in Table 4, the following compounds were used. It should be noted that a compound layer not containing an inorganic solid lubricant was formed in some of the steel sheets.

[0112] Molybdenum disulfide: LM-13 manufactured by Daito Lubricants Co., Ltd.

[0113] Graphite: GP-60S manufactured by Hitachi ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion amount | aaaaa | aaaaa |

| adhesion amount | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com