Preparation method of graphene

A technology of graphene and graphene, which is applied in the field of graphene preparation, can solve the problems of graphene agglomeration, hard-to-wash separation products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

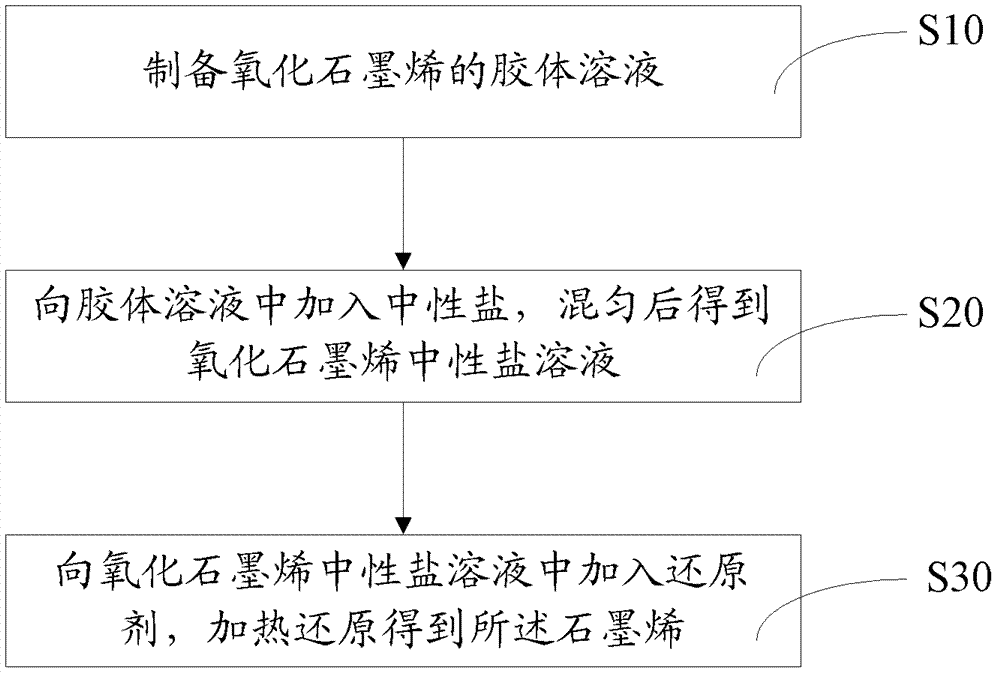

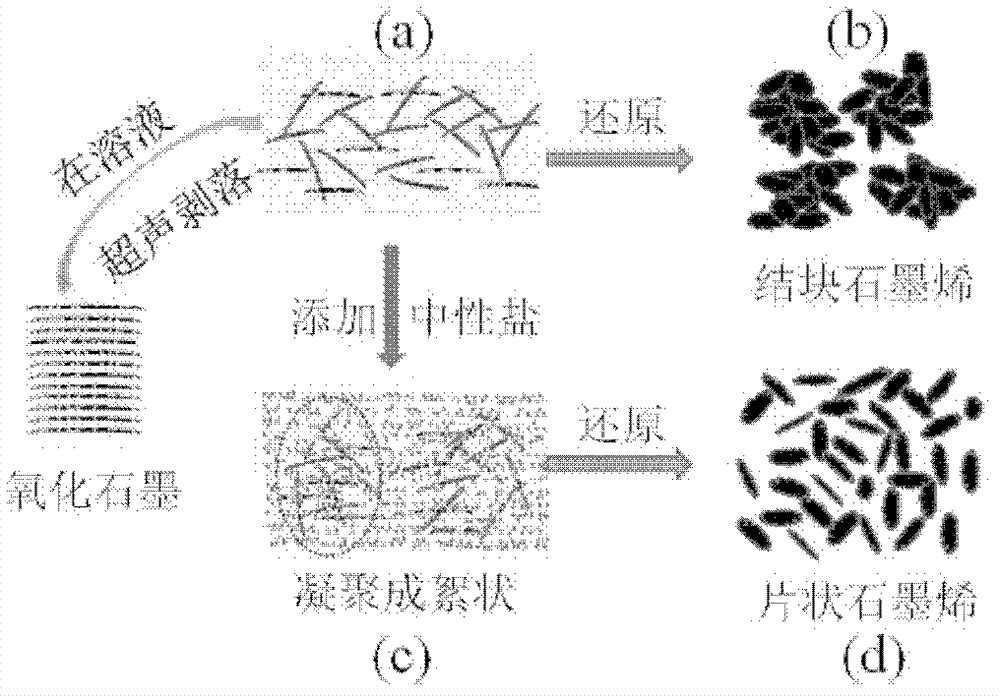

[0027] Such as figure 1 Shown, the preparation method of the graphene of one embodiment, comprises the steps:

[0028] Step S10, preparing a colloidal solution of graphene oxide:

[0029] First prepare graphite oxide, the following method can be adopted: mix concentrated sulfuric acid and graphite powder in the reactor evenly, heat to 70-80°C for oxidation for 4 hours, after cooling, sonicate for 2 hours, then dilute with deionized water, wash and dry , to obtain pretreated graphite powder; according to the Hummer oxidation method, it is oxidized with concentrated sulfuric acid, sodium nitrate and potassium permanganate to prepare fully oxidized graphite oxide. The preparation method of graphite oxide is not limited thereto.

[0030] Then mix the obtained graphite oxide with a solvent in a mortar and grind to obtain a jelly.

[0031] Finally, the obtained jelly is added to a solvent for ultrasonic stripping for 0.5-4 hours to obtain a colloidal solution of graphene oxide. ...

Embodiment 1

[0042] Weigh 5g of solid graphite powder and 30mL of concentrated sulfuric acid in a 500mL three-neck flask, mix evenly, heat the oil bath to 80°C for oxidation, take it out after 4 hours of reaction, and cool it down, sonicate it at 500W for 2 hours, and then use deionized water Dilute to 500mL, transfer to 1L container, dilute to 1L with deionized water, filter through 0.22μm filter, wash with deionized water to 1M BaCl 2 No white precipitate was detected, and then dried at 70° C. for 24 hours to obtain pretreated graphite powder.

[0043] Add the above-mentioned pretreated graphite powder into a 500mL three-necked flask, add 2.5g NaNO 3 and 120mL concentrated sulfuric acid, the three-necked flask was fixed in an ice-water bath and stirred for 30min, the temperature was controlled below 20°C; then 15g KMnO 4 After stirring for 2 hours, add 75mL of deionized water, heat up to 35±3°C and stir for 30min, add 75mL of deionized water, heat up to 98°C and stir for 15min, then add...

Embodiment 2-11

[0047] The reaction conditions such as the type of neutral salt and the type of reducing agent were changed to obtain Examples 2-11, and the results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com