High-purity SiCl4 purification method

A purification method and high-purity technology, applied in the direction of silicon halide compounds, halosilanes, etc., can solve the problems such as difficult separation of azeotrope impurities, achieve the effect of eliminating particle dust, eliminating polluted products, and overcoming poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

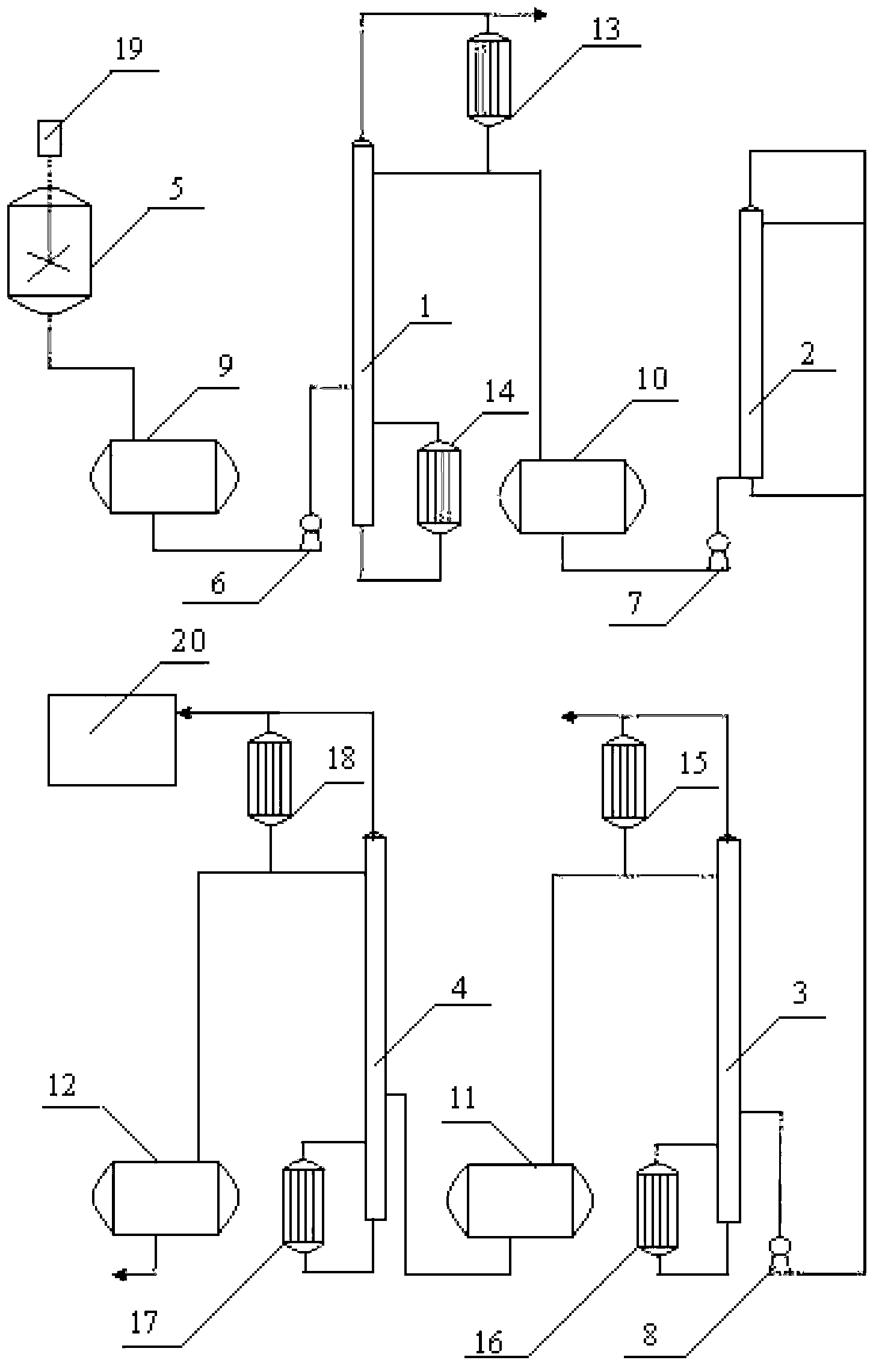

[0035] Specific implementation mode one: the high-purity SiCl of this implementation mode 4 The purification method is as follows:

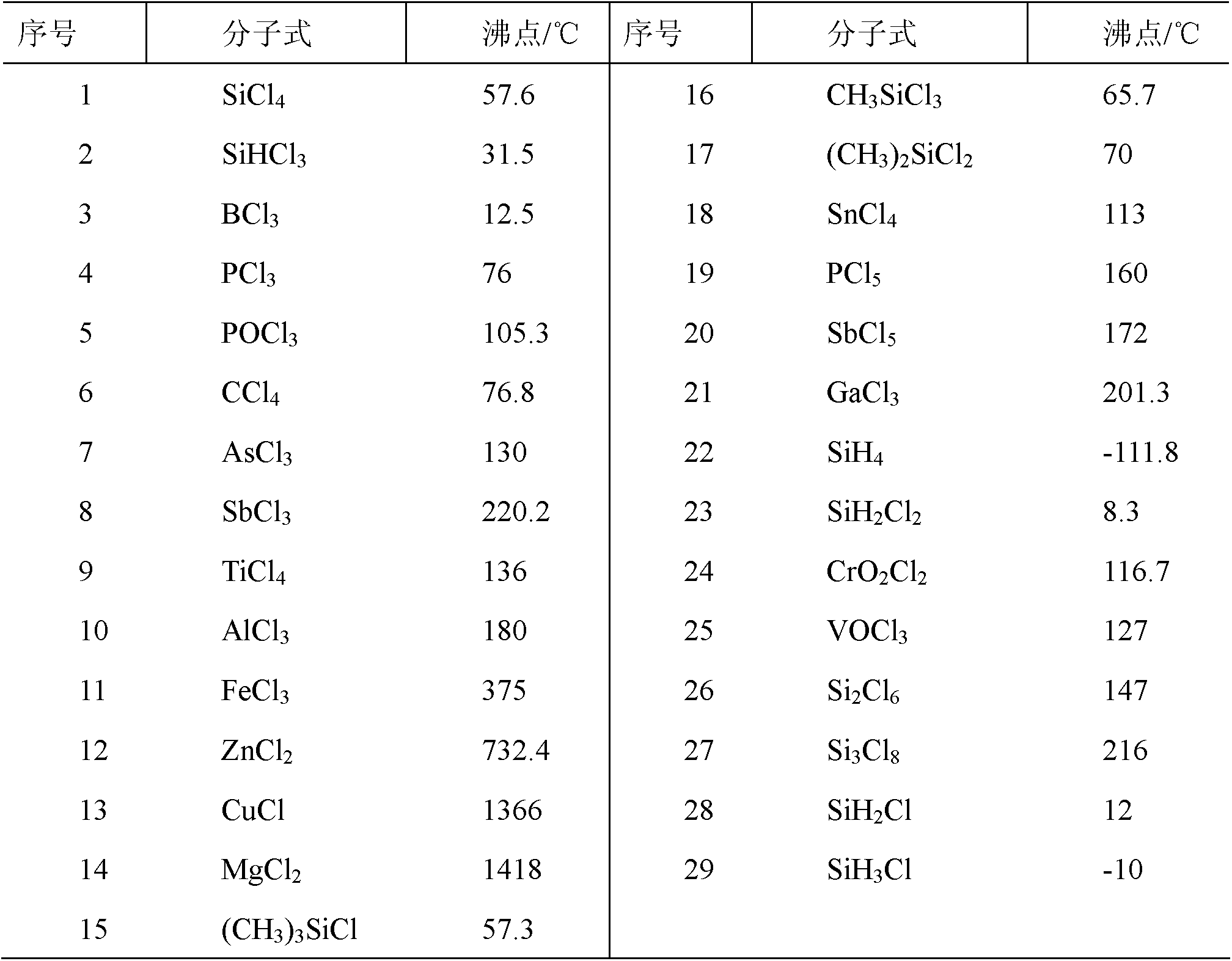

[0036] 1. The crude SiCl 4 , cuprous chloride or zinc chloride and inorganic salts are added to the reaction kettle, and the crude SiCl 4 The azeotrope reacts with the inorganic salt under the catalysis of cuprous chloride or zinc chloride for 20-60min, and the inorganic salt is Na 2 CO 3 or K 2 CO 3 , the dosage of cuprous chloride or zinc chloride is crude SiCl 4 0.01%-0.1% of the mass, the amount of inorganic salt added is based on the crude SiCl 4 The azeotrope content is determined to be 100.1%-102% of the azeotrope mass, and the reaction obtains a high boiling point mixture;

[0037] 2. The product of step 1 is pumped into the atmospheric rectification tower 1 through a canned pump, the heavy components are discharged from the bottom of the tower, and the light components are discharged from the top of the tower, SiCl 4 The crude re...

specific Embodiment approach 2

[0042] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the adsorbent filled in the adsorption column described in step three is silica gel modified by silane coupling agent γ-chloropropyl-triethoxysilane , Silane coupling agent γ-chloropropyl-trimethoxysilane modified silica gel, silane coupling agent γ-chloropropyl-dimethoxyethoxysilane modified silica gel or silane coupling agent γ-chloro Propyl-methoxydiethoxysilane modified silica gel. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the degree of vacuum described in Step 5 is -0.03MPa. Others are different from the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com