Small-scale farm organic matter on-site fermentation process and device

A fermentation device and organic matter technology, which is applied in the field of in-situ fermentation process of organic matter and its fermentation device in small farms, can solve the problems of high labor cost, uneven mixing, low site utilization rate, etc., achieve automatic control, reduce personnel input, The effect of high site utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

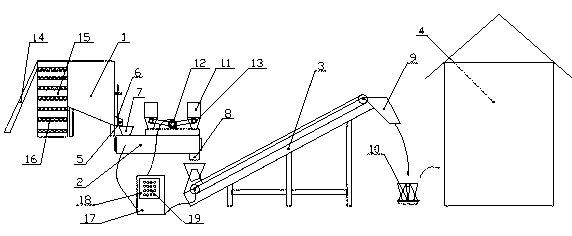

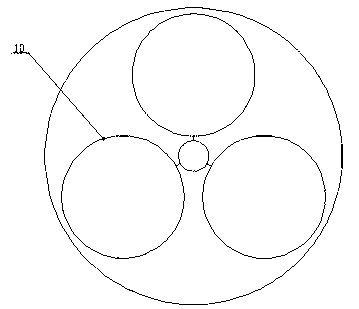

[0018] Referring to illustrations 1-2, a small-scale farm organic fertilizer in-situ fermentation device includes a feed bin 1, a screw conveyor 2, an inclined conveyor 3, a fermentation chamber 4 and a control box, the feed bin 1. A discharge port 5 is provided on the side wall of the lower part, and a manual valve 6 for controlling the discharge volume is provided on the discharge port 5. The feed port 7 of the screw conveyor 2 is located at the outlet of the feed bin 1. Below the feed port 5, in order to accept materials; the screw conveyor 2 is provided with an automatic feeding device for adding bacteria or trace elements, and the discharge port 8 of the screw conveyor 2 leads to the inclined conveyor 3, A rotatable bagging bracket 10 is provided below the outlet 9 of the inclined conveyor 3, and a storage bag is arranged on the rotatable bagging bracket 10, and the storage bags after loading and sealing are stacked on the Fermentation in fermentation chamber 4.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com