Nanometer photocatalyst spray-coating agent and preparation method thereof

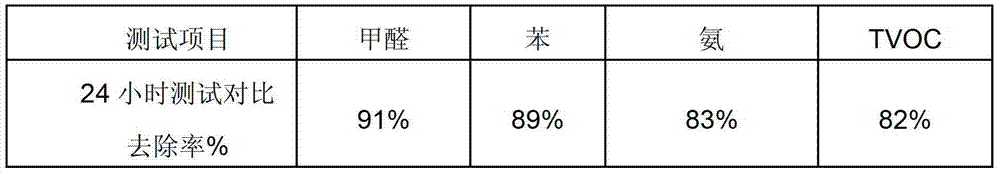

A nano-photocatalyst and spraying agent technology, used in the field of environmental pollution control, can solve the problems of limited lighting conditions and slow reaction speed, and achieve the effect of wide application range and excellent air pollution degradation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

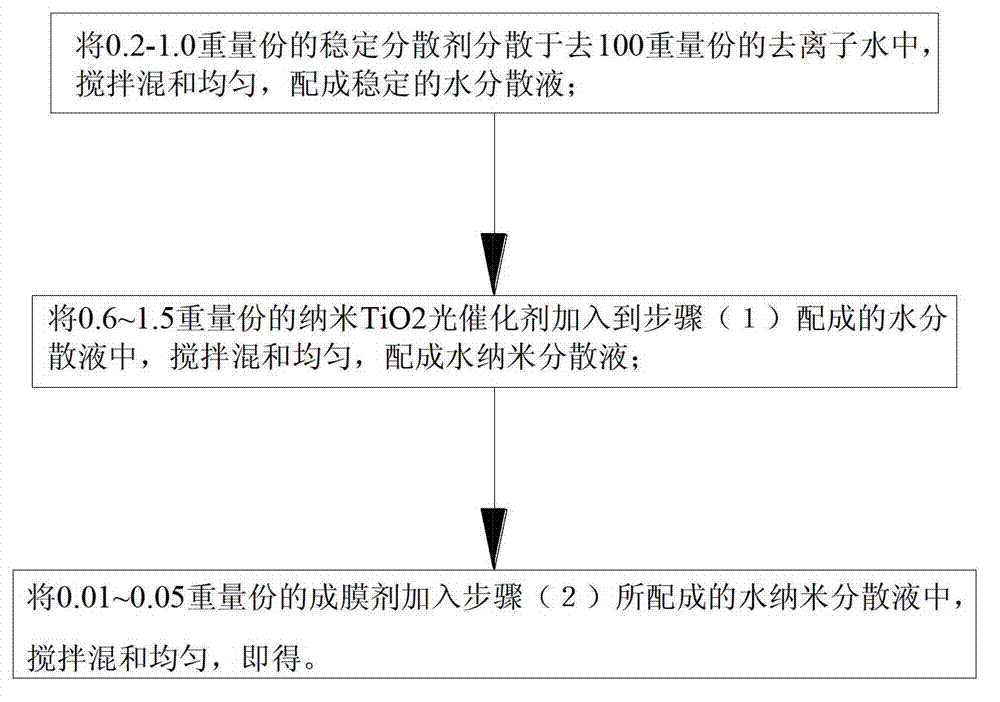

[0034] like figure 1 Shown, prepare nano photocatalyst spraying agent, comprise the following steps:

[0035] (1) Disperse 1.0 parts by weight of a stable dispersant in 100 parts by weight of deionized water, stir and mix evenly, and prepare a stable aqueous dispersion;

[0036] (2) 1.5 parts by weight of nano-TiO 2 Add the photocatalyst into the aqueous dispersion prepared in step (1), stir and mix evenly, and prepare the aqueous nano-dispersion;

[0037] (3) Add 0.05 parts by weight of film-forming agent into the aqueous nano-dispersion prepared in step (2), stir and mix evenly to obtain the product.

[0038] Among them, the film-forming agent is composed of the following components by weight percentage: 20% shellac, 20% gum arabic, 30% agar, 15% starch, and 15% polyvinyl alcohol.

[0039] Among them, the stable dispersant is sodium methylene bis-naphthalene sulfonate.

[0040] The nanophotocatalyst spraying agent prepared in this example has remarkable antibacterial (in...

Embodiment 2

[0043] like figure 1 Shown, prepare nano photocatalyst spraying agent, comprise the following steps:

[0044] (1) Disperse 0.8 parts by weight of a stable dispersant in 100 parts by weight of deionized water, stir and mix evenly, and prepare a stable aqueous dispersion;

[0045] (2) 1.2 parts by weight of nano-TiO 2 Add the photocatalyst into the aqueous dispersion prepared in step (1), stir and mix evenly, and prepare the aqueous nano-dispersion;

[0046] (3) Add 0.04 parts by weight of film-forming agent into the aqueous nano-dispersion prepared in step (2), stir and mix evenly to obtain the product.

[0047] Among them, the film-forming agent is composed of the following components by weight percentage: 30% shellac, 20% gum arabic, 30% agar, 10% starch, and 10% polyvinyl alcohol.

[0048] Wherein, the stable dispersant is sodium methylene bis-naphthalene sulfonate.

[0049] The nanophotocatalyst spraying agent prepared in this example has remarkable antibacterial (inhib...

Embodiment 3

[0052] like figure 1 Shown, prepare nano photocatalyst spraying agent, comprise the following steps:

[0053] (1) Disperse 0.5 parts by weight of a stable dispersant in 100 parts by weight of deionized water, stir and mix evenly, and prepare a stable aqueous dispersion;

[0054] (2) 0.8 parts by weight of nano-TiO 2 Add the photocatalyst into the aqueous dispersion prepared in step (1), stir and mix evenly, and prepare the aqueous nano-dispersion;

[0055] (3) Add 0.02 parts by weight of film-forming agent into the aqueous nano-dispersion prepared in step (2), stir and mix evenly to obtain the product.

[0056] Wherein, the film-forming agent is calculated by weight percentage and consists of the following components: 40% gum arabic, 30% agar, 15% starch, and 15% polyvinyl alcohol.

[0057] Wherein, the stable dispersant is sodium methylene bis-naphthalene sulfonate.

[0058] The nanophotocatalyst spraying agent prepared in this example has remarkable antibacterial (inhibiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com