Thermochromic composite powder with core-shell structure and preparation method of powder

A thermochromic and composite powder technology, which is applied in heat treatment technology, wet chemical treatment technology, and hydrothermal treatment technology, can solve the problems of losing thermochromic properties, achieve improved visible light transmittance, excellent performance, and enhanced chemical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention relates to a "rattle" type thermochromic hollow structure and a preparation method thereof, so as to reduce VO 2 The particle size of the powder reduces the refractive index of the film, reduces the heat exchange between indoor and outdoor, and increases the VO 2 Optical properties of the base film. "Ratter" type structure refers to a structure with a solid core in a hollow shell, also known as a core-shell material with a movable core, which can be regarded as a special hollow material.

[0043] Specifically, the structure of a "Rattle" type thermochromic powder is first provided, the movable inner core part is vanadium dioxide thermochromic powder, the outer shell is a transparent oxide, and the space between the outer shell and the inner core is air or vacuum. In order to ensure good optical performance, the minimum dimension in the three-dimensional dimension of the "rattle" type structure must be below 200 nanometers, preferably below 100 nanometers,...

Embodiment 1

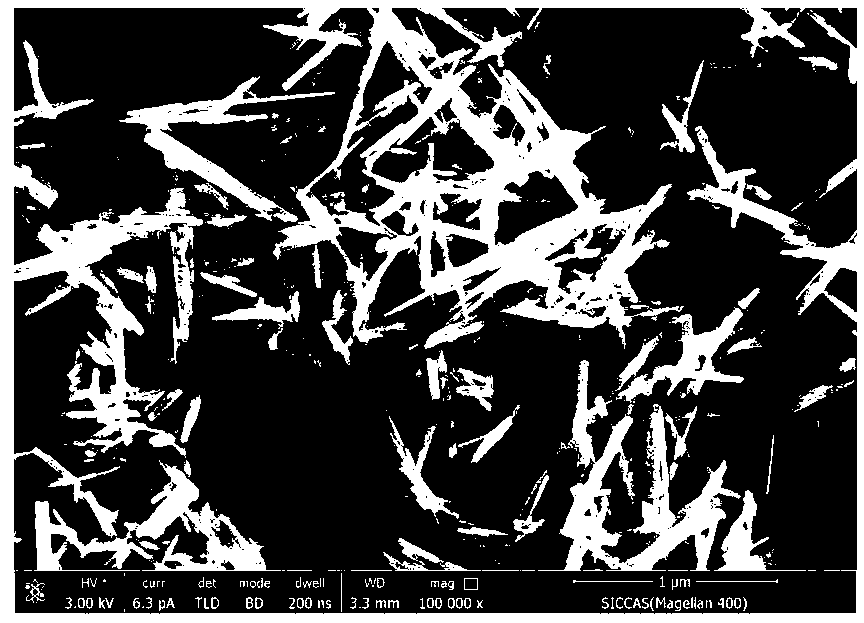

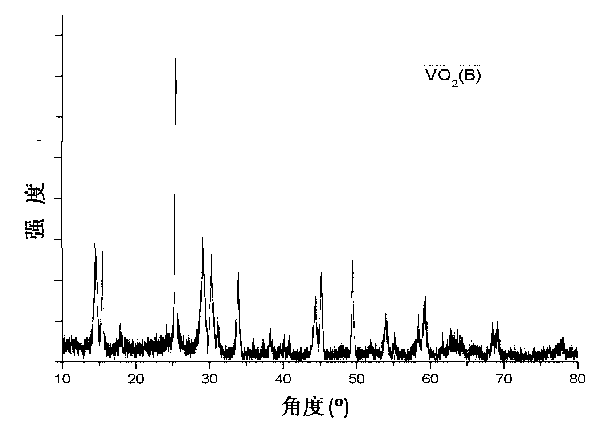

[0054] Weigh 1.0g of vanadium pentoxide, 5.0ml of ethylene glycol and 40ml of deionized water and place it in a hydrothermal kettle, keep at 160-320°C for 1-48 hours, and cool to obtain blue-black powder, see figure 1 and figure 2 , which respectively show the SEM image and XRD image of vanadium dioxide in the present embodiment, indicating that it is the B phase;

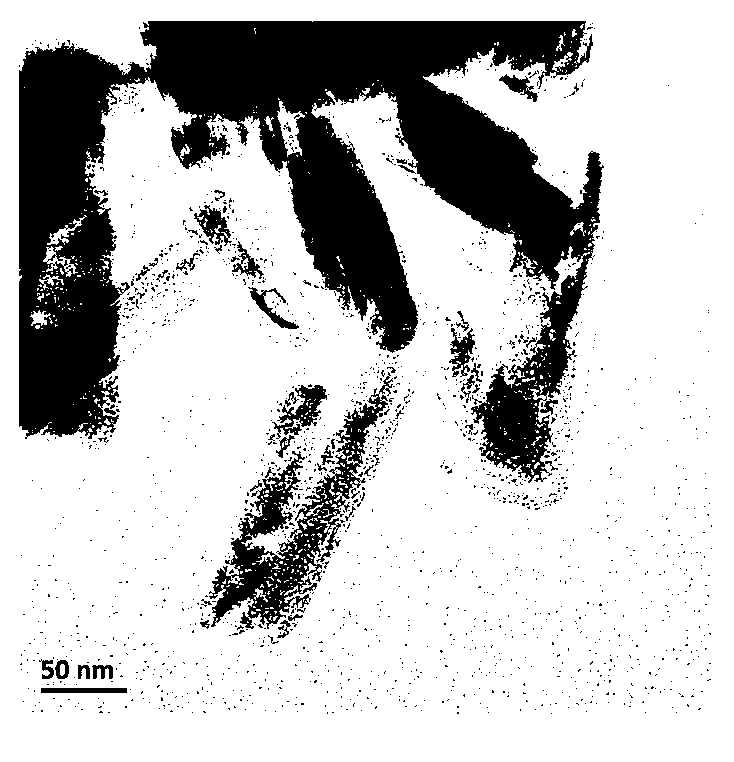

[0055] Then put the blue-black powder into a 1:4 weight percent solution of 50 ml of deionized water and absolute ethanol, after ultrasonic dispersion for 30 minutes, adjust the pH to 11 with ammonia water, and slowly add 1 mL of ethyl orthosilicate to it, stir After 4 hours, it was filtered, washed and dried at 110 °C for 2 hours to obtain a silica-wrapped vanadium dioxide core-shell structure (VO 2 SiO 2 ), see image 3 , which shows the SEM image of the B-phase of silica-coated vanadium dioxide in the present implementation;

[0056] Weigh a small amount of the above silica-coated vanadium dioxide powder (V...

Embodiment 2

[0060] Weigh 1.0g of vanadium pentoxide and 1.8ml of hydrazine solution, place in 40ml of deionized water and stir until completely dissolved to obtain a tetravalent vanadium ion precursor solution, keep at 160-320 ° C for 1-48 hours, and cool to obtain black powder , see Image 6 and Figure 7 , which respectively show the SEM image and XRD image of vanadium dioxide in the present embodiment, indicating that it is M phase;

[0061] Then put the black powder into a 1:4 weight percent solution of 50 ml of deionized water and absolute ethanol, after ultrasonic dispersion for 30 minutes, adjust the pH to 11 with ammonia water, and slowly add 1 mL of ethyl orthosilicate to it, stir for 4 After 1 hour, it was filtered, washed and dried at 110 °C for 2 hours to obtain a silica-wrapped vanadium dioxide (M) core-shell structure (VO2 SiO 2 ), see Figure 8 , which shows the SEM image of the silica-coated vanadium dioxide M phase in the present implementation;

[0062] The obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com