Pulsation wire mesh catalytic burning device and method

A wire mesh and catalytic combustion technology, which is applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems that the reaction rate is controlled by diffusion, and the preparation process of the wire mesh carrier is complicated, and achieves a simple and compact structure. , The effect of less pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

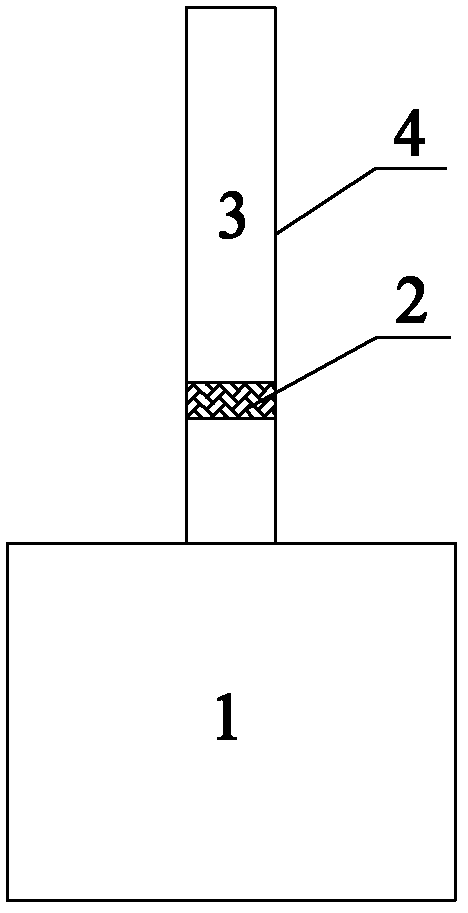

[0037]The pulsating wire mesh catalytic combustion device of the present invention is composed of an acoustic decoupling chamber, a Rijke type pulsating burner body, a wire mesh catalytic bed, and a heat exchange cooling device, wherein the integral metal mesh catalytic bed has a three-dimensional The honeycomb wire mesh carrier with a mesh structure is located at 1 / 4 of the height of the Rijke tube on the upper part of the acoustic decoupling chamber to meet the needs of production processes such as rubber, synthetic leather, pharmaceuticals, enameled wire, printed matter, shoes, paint, etc. Purification of volatile organic pollutants (VOCs) is required.

Embodiment 2

[0039] The pulsating wire mesh catalytic combustion device of the present invention is composed of an acoustic decoupling chamber, a Rijke type pulsating burner body, a metal mesh catalytic bed, and a heat exchange cooling device. The metal mesh catalytic bed layer at the height of 8-1 / 3 is stacked by several short-channel wire meshes with sinusoidal structure, triangular structure or square structure to meet the pollutants in organic waste gas emitted from stationary sources (such as Hydrocarbons, halogenated hydrocarbons, aromatic hydrocarbons, polycyclic aromatic hydrocarbons, acetone, pyridine, ethyl acetate, etc.) purification needs.

Embodiment 3

[0041] The pulsating wire mesh catalytic combustion device of the present invention is composed of an acoustic decoupling chamber, a Rijke type pulsating burner body, a metal mesh catalytic bed, and a heat exchange cooling device. The metal mesh catalytic bed at the height of 8~1 / 2 is composed of upper and lower metal mesh catalytic beds. The bottom catalytic layer is mainly used for the oxidation reaction of hydrogen, while the top catalytic layer is mainly used for the oxidation reaction of CO. In order to meet the needs of blast furnace gas, synthesis gas-based metallurgical reducing gas tail gas, biomass and combustible waste gasification gas rich in H, which are mainly evacuated in the iron and steel industry 2 The efficient utilization of low calorific value gases and the need for pollutant emission reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com