Steam condensate corrosion inhibitor for industrial boiler

A technology for steam condensate water and industrial boilers, which is used in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. Corrosion, low cost of water treatment, low dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

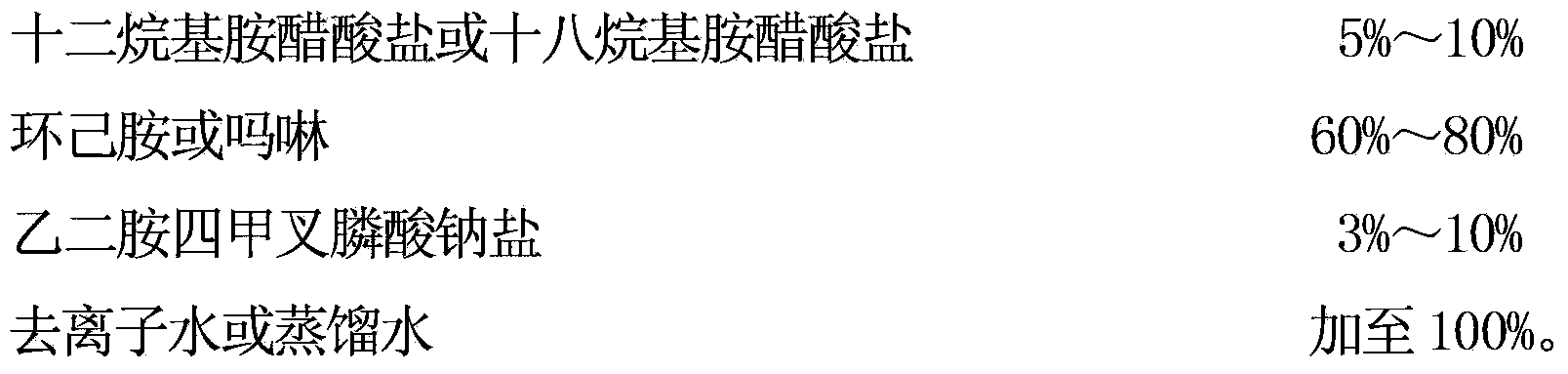

[0019] Taking the preparation of 1000g industrial boiler steam condensate corrosion inhibitor as an example, the raw materials used and their mass ratios are as follows:

[0020]

[0021] The preparation method of the above-mentioned industrial boiler steam condensate corrosion inhibitor is as follows: according to the mass ratio of the above-mentioned raw materials, octadecylamine acetate, cyclohexylamine, ethylenediamine tetramethylene phosphonate, and deionized water are added In a reaction kettle, heat to 70°C, stir until it is completely dissolved, cool to room temperature, and pack it into packaging barrels to obtain an industrial boiler steam condensate corrosion inhibitor.

Embodiment 2

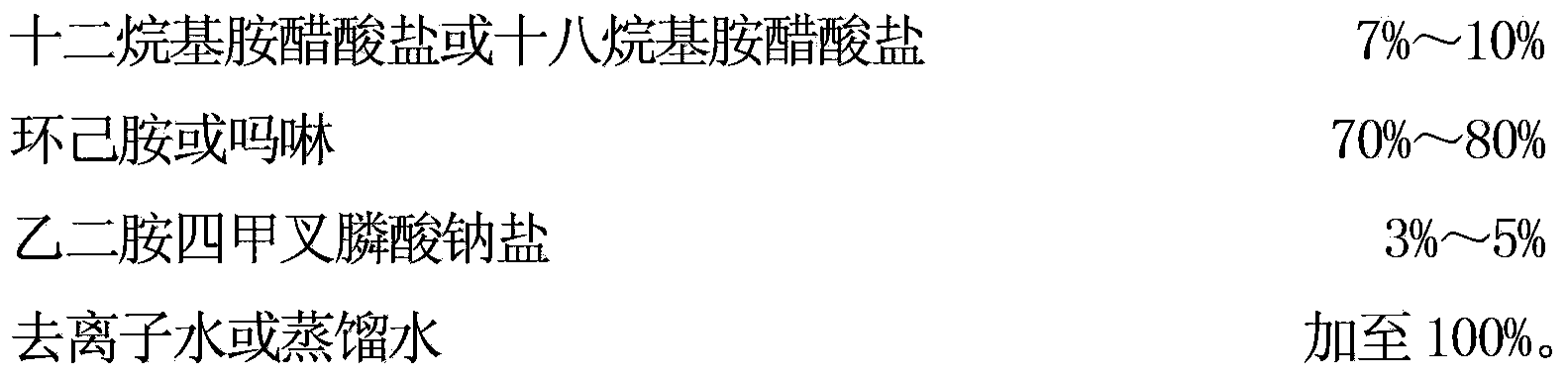

[0023] Taking the preparation of 1000g industrial boiler steam condensate corrosion inhibitor as an example, the raw materials used and their mass ratios are as follows:

[0024]

[0025] The preparation method of the industrial boiler steam condensate corrosion inhibitor is the same as that of Example 1.

Embodiment 3

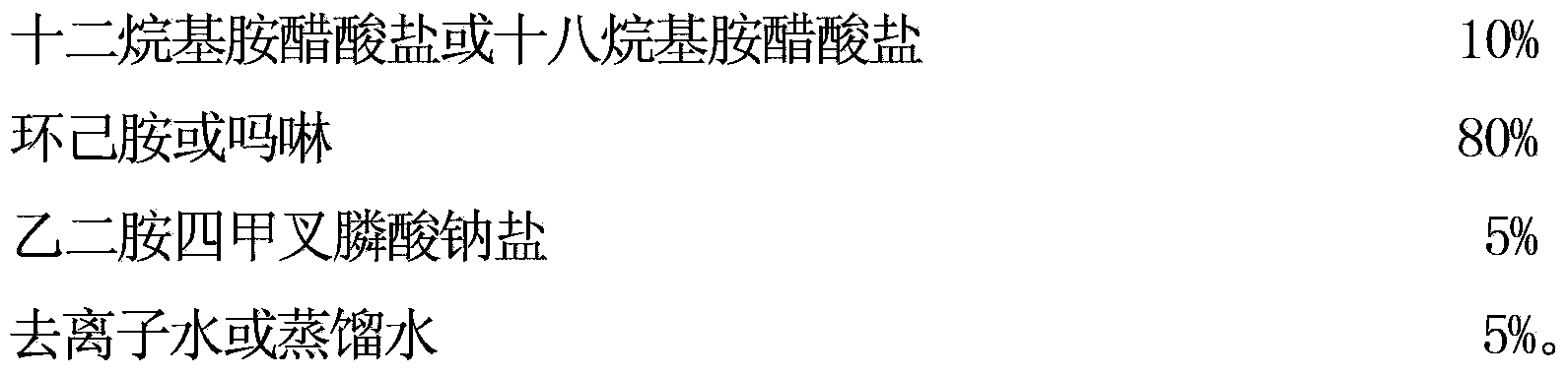

[0027] Taking the preparation of 1000g industrial boiler steam condensate corrosion inhibitor as an example, the raw materials used and their mass ratios are as follows:

[0028]

[0029] The preparation method of the industrial boiler steam condensate corrosion inhibitor is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com