Cement concrete strength promoter and preparation method thereof

A technology of cement concrete and accelerator, applied in the field of building materials, can solve the problems of large water absorption, less than 10% utilization rate of phosphogypsum, environmental pollution, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

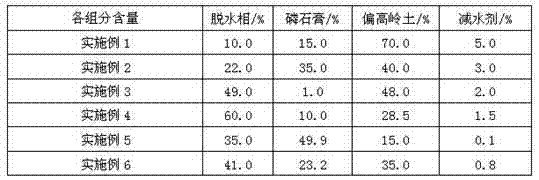

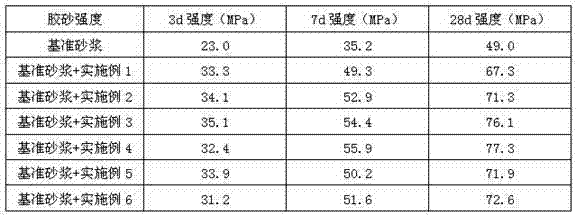

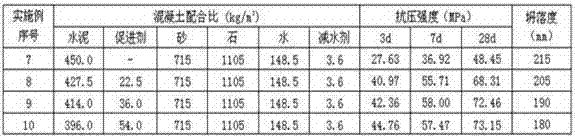

Embodiment 1

[0019]A cement concrete strength accelerator, it is made up of cement slurry dehydration phase, metakaolin, phosphogypsum, and water reducer, and its weight percentage of each component is as shown in Table 1, wherein, the cement slurry dehydration phase follows the steps Preparation: 1) Firstly, the waste concrete is separated and crushed to a certain extent, the large aggregates are removed, and the waste cement slurry is selected, and then crushed, ground and sieved, and the sieve of 0.075mm sieve is taken , which is the powder; 2) The obtained powder was calcined at a temperature of 750°C for 4 hours, and rapidly cooled to room temperature at a cooling rate of 50°C / min to obtain a dehydrated cement slurry phase. Metakaolin is prepared according to the following steps: 1) First, put a large piece of kaolin into a ball mill for 30 minutes of grinding to obtain kaolin powder; 2) Calcinate the kaolin powder at a temperature of 700°C for 6 hours, and put it into a ball mill afte...

Embodiment 2

[0029] A cement concrete strength accelerator, the weight percentage of each component is shown in Table 1, wherein the cement paste dehydration phase is prepared according to the following steps: 1) Firstly, the waste concrete is separated and crushed to remove large pieces Aggregate, select the waste cement slurry, and then after crushing and grinding for 30 minutes, sieve, and take the sieve of 0.075mm sieve, which is the powder; 2) Put the obtained powder at a temperature of 1000℃ Calcined for 0.5 hours, then rapidly cooled to room temperature at a cooling rate of 80°C / min to obtain a dehydrated cement paste phase. Metakaolin is prepared according to the following steps: 1) First, put a large piece of kaolin into a ball mill for 20 minutes of grinding to obtain kaolin powder; 2) Calcinate the kaolin powder at a temperature of 1000°C for 1 hour, cool it and put it into a ball mill Medium grinding for 20min until the specific surface area is 8000m 2 / kg to get metakaolin. ...

Embodiment 3-6

[0033] A cement concrete strength accelerator, the weight percentage of each component is shown in Table 1, wherein the cement paste dehydration phase is prepared according to the following steps: 1) Firstly, the waste concrete is separated and crushed to remove large pieces Aggregate, select the waste cement slurry, and then after crushing, grinding, sieving, take the sieve of 0.075mm sieve, which is the powder; 2) Calcinate the obtained powder at a temperature of 500°C for 6 Hours, rapidly cooled to room temperature at a cooling rate of 120°C / min to obtain the dehydrated phase of the cement slurry. Metakaolin is prepared according to the following steps: 1) Firstly, put a large piece of kaolin into a ball mill for 40 minutes of grinding to obtain kaolin powder; 2) Calcinate the kaolin powder at a temperature of 550°C for 4 hours, and put it into Grind in a ball mill for 25 minutes until the specific surface area is 15000m 2 / kg to get metakaolin. The preparation process of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com