Method and device for producing furfural by using biomass hydrolysis coupling pervaporation separation technology

A technology of pervaporation and pervaporation membrane is applied in the field of hydrolysate separation in biomass hydrolysis process, which can solve problems such as great difficulty and achieve the effects of improving yield, good application prospect and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

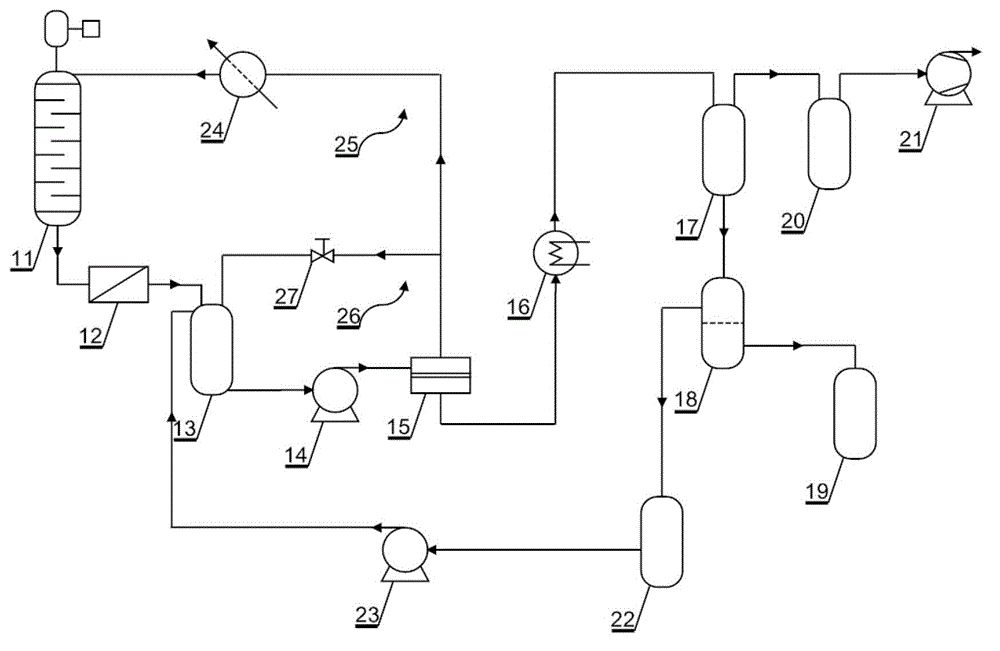

[0068] Using corncobs as biomass raw materials, continuous biomass hydrolysis coupled with pervaporation separation to produce furfural, the schematic diagram of the process is shown in figure 1 .

[0069] 1. Biomass hydrolysis to obtain furfural-containing hydrolyzate

[0070]Add corncobs that have been mechanically crushed and have a particle size of less than 2 cm into the hydrolysis device 11, and add sulfuric acid solution with a concentration of 10 g / L. The volume ratio (solid-to-liquid ratio) of corncobs to sulfuric acid solution is 1:8. Turn on the stirring motor on the hydrolysis device for acid mixing operation, so that the sulfuric acid solution is evenly distributed and fully in contact with the corn cob. Start the heater of the hydrolysis device to maintain the temperature in the hydrolysis device at about 160°C for hydrolysis.

[0071] 2. The furfural-containing hydrolyzate is filtered to obtain the furfural-containing hydrolyzate from which solids have been re...

Embodiment 2

[0085] The production process of Example 2 is the same as that of Example 1. The difference from Example 1 is that after the temperature in the hydrolysis device is maintained at 160°C for 3 hours, the valve at the lower end of the hydrolysis device is opened to carry out the biomass hydrolysis coupling pervaporation separation process, and the feed liquid The concentration and temperature of furfural in storage tank 13 are 3.0wt% and 90°C respectively. The concentration of furfural in the aqueous furfural concentrate obtained through pervaporation membrane separation is 80.17wt%, and the actual yield of furfural is 93%.

Embodiment 3

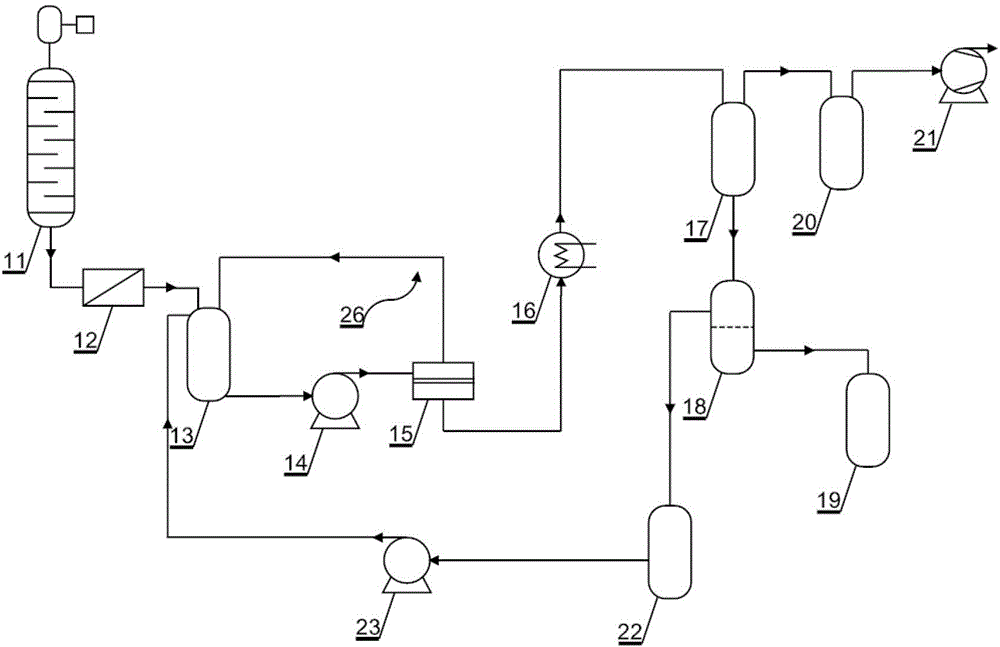

[0087] Using sweet sorghum stalks as biomass raw materials, furfural is produced by intermittent biomass hydrolysis coupled with pervaporation separation. The process flow diagram is shown in figure 2 .

[0088] 1. Biomass hydrolysis to obtain furfural-containing hydrolyzate

[0089] Put mechanically pulverized sweet sorghum stalks with a particle size of less than 0.5 cm into the hydrolysis device 11 and add acetic acid solution with a concentration of 30 g / L. The volume ratio (solid-to-liquid ratio) of sweet sorghum to acetic acid solution is 1:10. Turn on the stirring motor on the hydrolysis device for acid mixing operation, so that the acetic acid solution is evenly distributed and fully in contact with the sweet sorghum stalks. Turn on the heater of the hydrolysis device, and the temperature in the hydrolysis device is maintained at about 160°C.

[0090] 2. The furfural-containing hydrolyzate is filtered to obtain the furfural-containing hydrolyzate from which solids h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com