Crystalline silicon and preparation method thereof

A technology of crystalline silicon and monocrystalline silicon, applied in the field of crystalline silicon and its preparation, can solve the problems of accumulation of dislocations, high cost of casting monocrystalline silicon wafers, and low conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

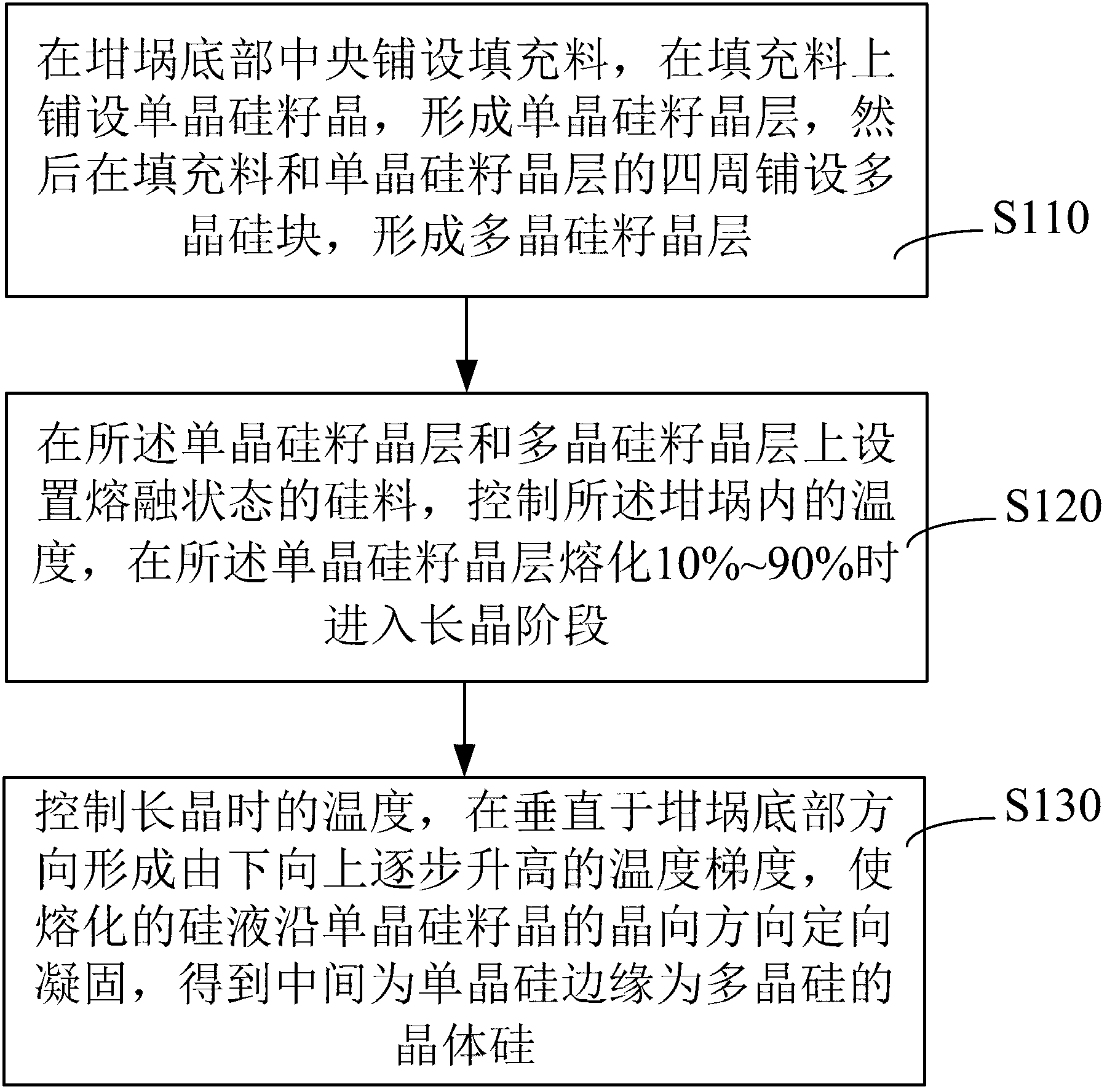

[0019] Please refer to figure 1 and figure 2 , a method for preparing crystalline silicon according to one embodiment, comprising the following steps.

[0020] Step S110, laying a filling material in the center of the bottom of the crucible, laying a monocrystalline silicon seed crystal on the filling material to form a monocrystalline silicon seed crystal layer, and then laying polycrystalline silicon blocks around the filling material and the monocrystalline silicon seed crystal layer to form a polycrystalline silicon seed crystal layer.

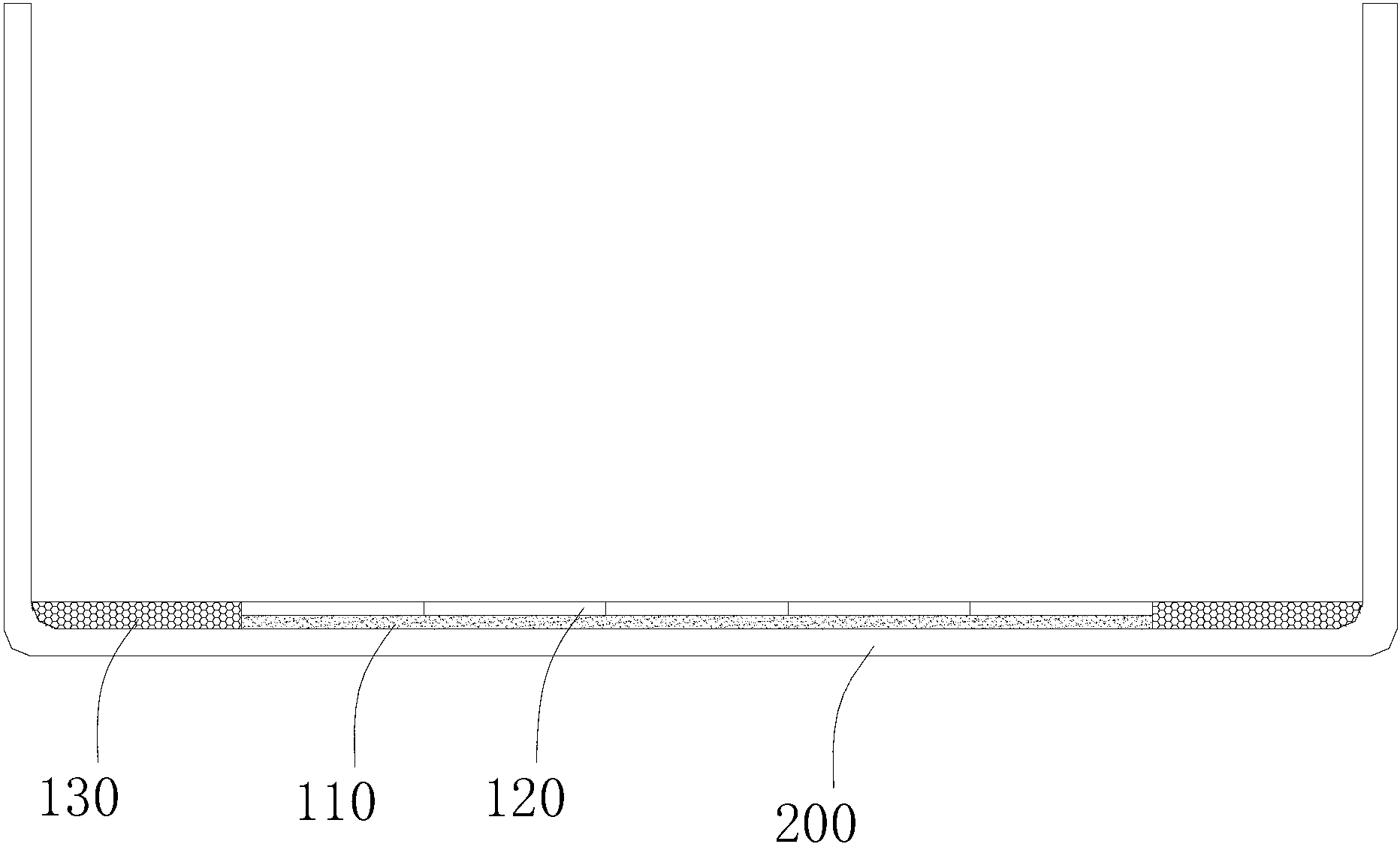

[0021] Please refer to figure 2 , in the center of the bottom of the crucible 200, the filling material 110 is first laid, and then the single crystal silicon seed crystal is laid on the filling material 110 to form the single crystal silicon seed crystal layer 120, and then the filling material 110 and the single crystal silicon seed crystal layer 120 A polysilicon block is laid around to form a polysilicon seed crystal layer 130 . ...

Embodiment 1

[0033] like figure 2 As shown, the filler is laid in the center of the bottom of the crucible, the monocrystalline silicon seed crystal is laid on the filler to form a monocrystalline silicon seed layer, and the polycrystalline silicon block is laid around the monocrystalline silicon seed layer and the filler to form a polycrystalline silicon seed layer. The filling material is silicon powder, and the thickness is 15mm. The size of the monocrystalline silicon seed crystal is 160×160×15mm, and there are 9 pieces in total, which are closely arranged in 3×3. The size of the polycrystalline silicon blocks laid around the monocrystalline silicon seed crystal is 140×140×25 mm.

[0034] Setting the silicon material in molten state on the monocrystalline silicon seed crystal layer and the polycrystalline silicon seed crystal layer is as follows: put 500 kg of polycrystalline silicon material on the polycrystalline silicon seed crystal layer and the monocrystalline silicon seed cryst...

Embodiment 2

[0036] like figure 2 As shown, the filler is laid in the center of the bottom of the crucible, the monocrystalline silicon seed crystal is laid on the filler to form a monocrystalline silicon seed layer, and the polycrystalline silicon block is laid around the monocrystalline silicon seed layer and the filler to form a polycrystalline silicon seed layer. Among them, the filling material is a silicon block with a size of 156×156×10mm, a total of 9 pieces, which are closely arranged in 3×3 at the bottom of the crucible. The size of the monocrystalline silicon seed crystal is 120×120×10mm, and there are 16 pieces in total, which are closely arranged in 4×4. The size of the polycrystalline silicon blocks laid around the monocrystalline silicon seed crystal is 156×156×20 mm.

[0037] Setting the silicon material in molten state on the monocrystalline silicon seed crystal layer and the polycrystalline silicon seed crystal layer is as follows: put 450 kg of polycrystalline silicon ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com