Method of manufacturing thin film cell and thin film cell

A technology of thin film battery and manufacturing method, which is applied in the fields of micro-nano photonics and photovoltaics, can solve problems such as inapplicability to thin-film Si-based batteries, and achieve the effects of improving battery efficiency, high cost performance, and high-efficiency light trapping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The manufacturing method of the thin film battery provided by the present invention and the specific implementation of the thin film battery will be described in detail below in conjunction with the accompanying drawings.

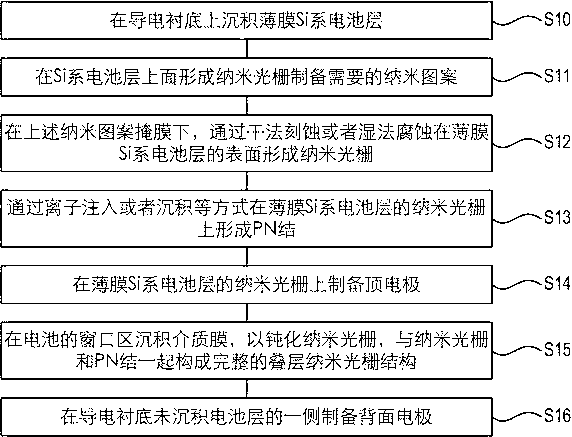

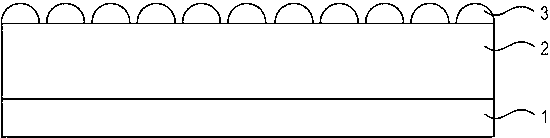

[0027] attached figure 1 Shown is a schematic diagram of the steps of a specific embodiment of the method of the present invention, including: Step S10, depositing a thin film Si-based battery layer on a conductive substrate; Step S11, forming a nano-grating on the Si-based battery layer to prepare nano-patterns; Step S12, under the above-mentioned nano-pattern mask, form a nano-grating on the surface of the thin-film Si-based battery layer by dry etching or wet etching; Step S13, form a nano-grating on the surface of the thin-film Si-based battery layer by ion implantation or deposition Form a PN junction on the grating; Step S14, prepare the top electrode on the nano-grating of the thin-film Si-based battery layer; Step S15, deposit a dielectric fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com