Autoclaved aerated concrete masonry block and production method thereof

A concrete block, autoclaved and gas-filled technology, which is applied to building components, molds, ceramic molding machines, etc., can solve the problems of increased product storage and transportation costs, hidden dangers of building safety, and large manual labor, so as to reduce the amount of raw materials and reduce Effects of weight and heat cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

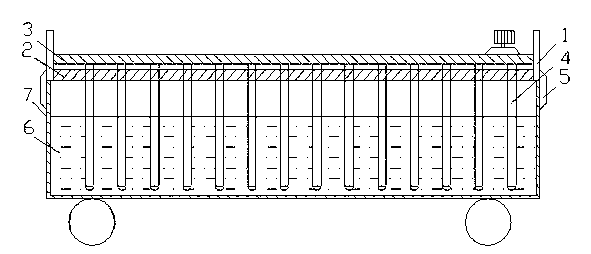

[0032] Refer to attached figure 1 Shown, a kind of production method of autoclaved aerated concrete block comprises the following steps:

[0033] (1), inject the slurry 6 into the mold box 7;

[0034] (2), fixing at least one mandrel 4 on the mold box 4 through a positioning device, and each mandrel 4 is partially immersed in the slurry 6;

[0035] (3), place the mold box 7 in the step (2) in the drying room, rest and foam until the slurry is shaped into a green body;

[0036] (4) Pull out the mandrel 4 after rotating the mandrel 4 until it becomes loose, and separate the mandrel 4 from the mold box 7;

[0037] (5), turning over, cutting, and steaming the green body shaped in step (3);

[0038] Wherein: the positioning device in step (2) includes a mold base 1, a mounting plate 3 fixedly arranged on the mold base 1, a fixing plate 2 detachably arranged on the mold base 1, and a locking device 5, so that The mounting plate 3 has a plurality of grooves, the fixing plate 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com