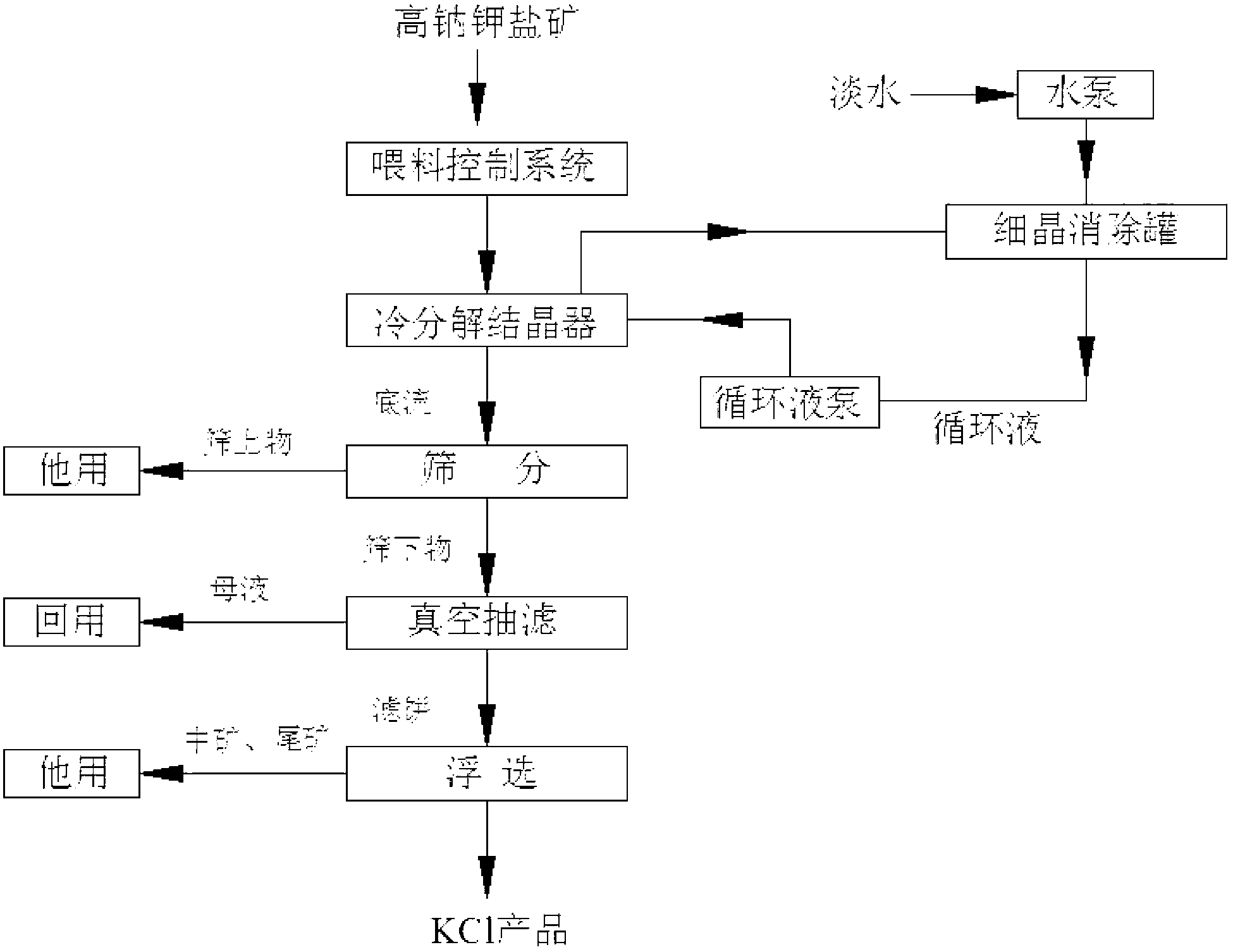

System and processing of the preparation of potassium chloride in lare grains by cold decomposition crystallization of high sodium potassium salt ore and flotation method

A technology of cold decomposition and potassium chloride, applied in the direction of alkali metal chloride, etc., to achieve the effect of improving market competitiveness, reducing equipment operating costs, and having broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

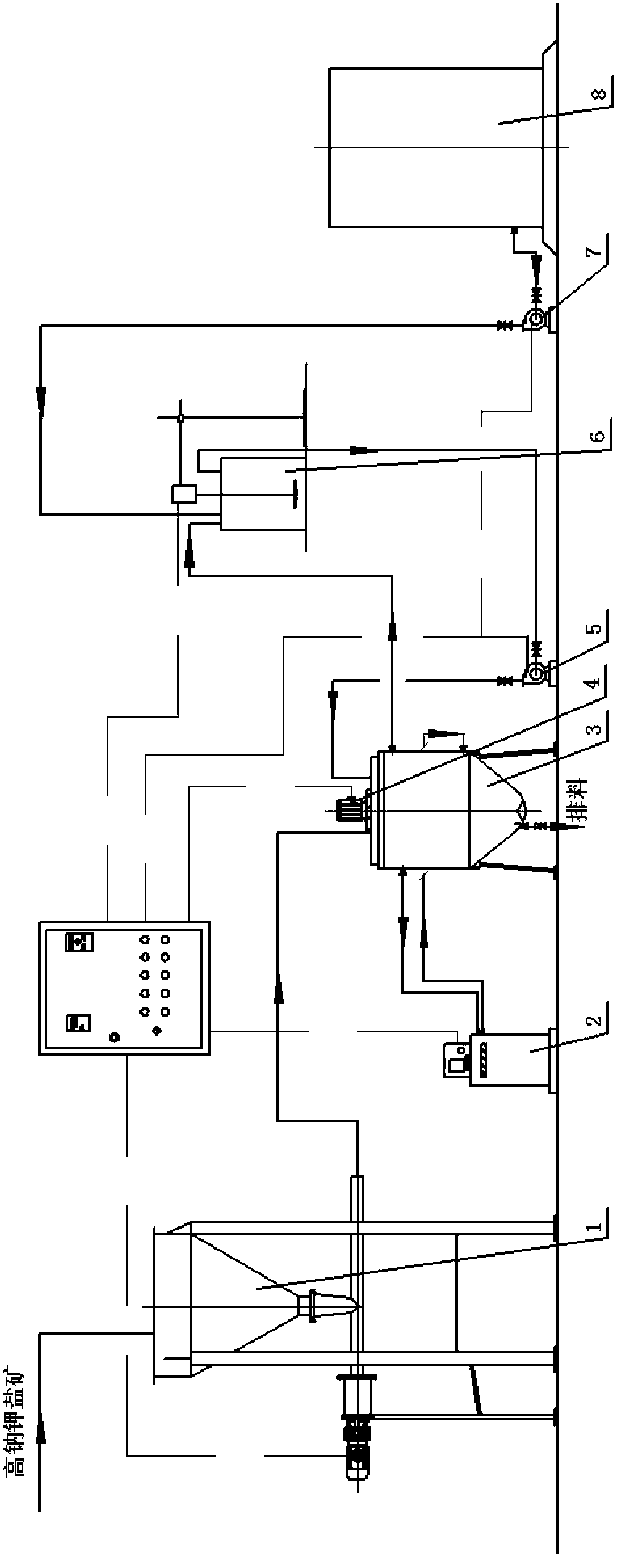

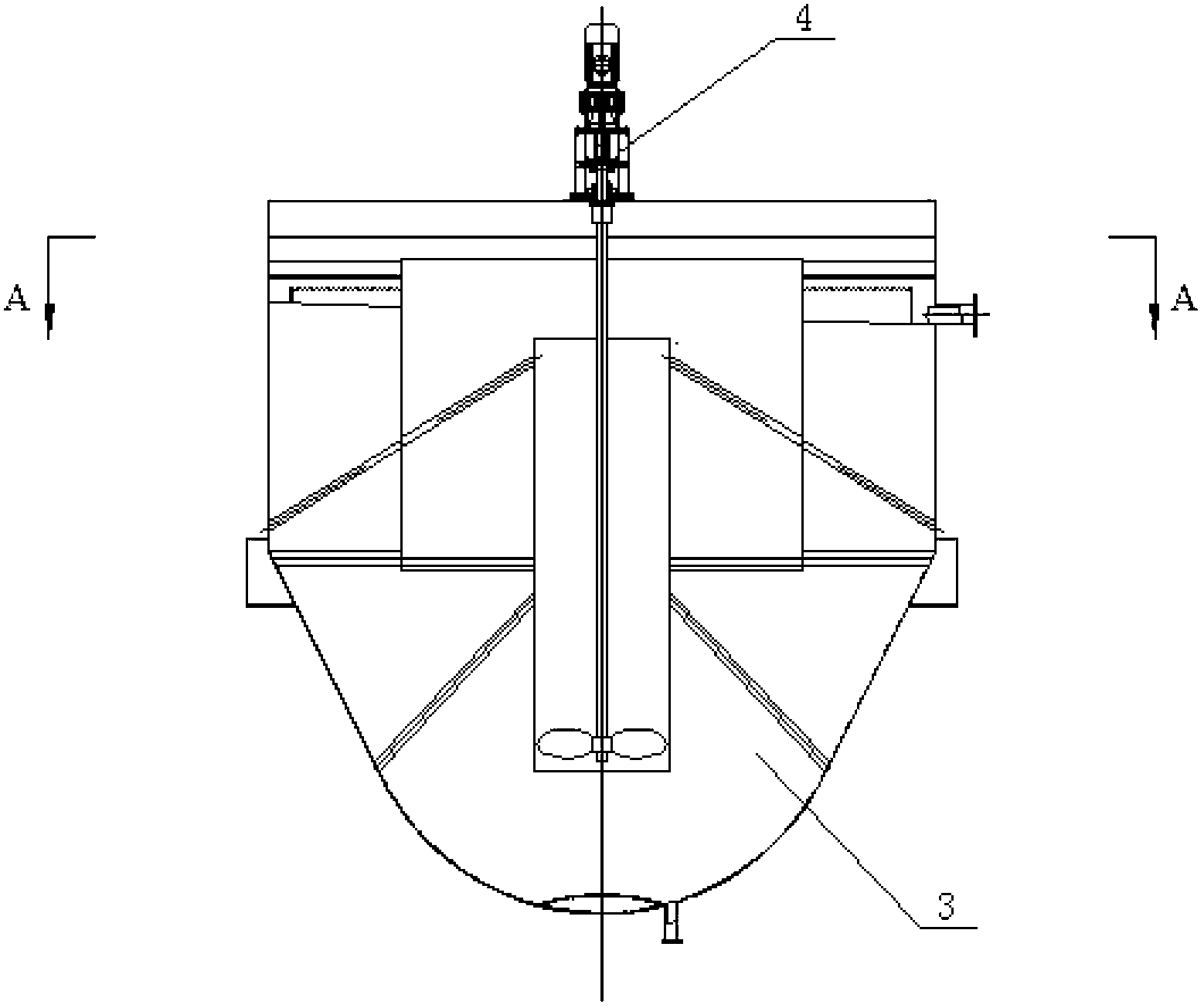

[0032] A kind of technology of cold decomposition crystallization and flotation method of high-sodium potassium salt ore to prepare large particle potassium chloride, concrete steps are as follows:

[0033] (1) The high-sodium potassium salt ore with a mass percentage of sodium chloride of 29.84% is sieved through a standard sieve with a sieve diameter of 4 mm, and the under-sieve is used as feed and continuously fed into the cold decomposition crystallizer by a continuous screw feeding system. The feeding rate of high-sodium potassium salt ore is 2.38kg / h, and the MgCl in the circulating liquid 2 The mass percent concentration is 23%, the residence time of the crystallizer is 3.55 hours, the operating temperature is 25°C, the stirring speed of the propulsion type stirring paddle is 400rpm, and the large particle potassium chloride product is obtained in the crystallizer.

[0034] (2) The potassium chloride fine crystal product obtained at the top of the crystallizer in step (...

Embodiment 2

[0039] A kind of technology of cold decomposition crystallization and flotation method of high-sodium potassium salt ore to prepare large particle potassium chloride, concrete steps are as follows:

[0040] (1) The high-sodium potassium salt ore with a mass percentage of sodium chloride of 42.50% is sieved through a standard sieve with a sieve diameter of 6mm, and the undersieve is used as feed and continuously fed into the cold decomposition crystallizer by a continuous screw feeding system. The feeding rate of sodium potassium salt ore is 3.95kg / h, and the MgCl in the circulating liquid 2 The mass percentage concentration is 25%, the residence time of the crystallizer is 2.26 hours, the operating temperature is 27°C, the stirring speed of the straight stirring paddle is 600rpm, and the large particle potassium chloride product is obtained in the crystallizer.

[0041] (2) The potassium chloride fine crystal product obtained at the top of the crystallizer in step (1) enters t...

Embodiment 3

[0046] A kind of technology of cold decomposition crystallization and flotation method of high-sodium potassium salt ore to prepare large particle potassium chloride, concrete steps are as follows:

[0047] (1) The high-sodium potassium salt ore with a mass percentage of sodium chloride of 39.06% is sieved through a standard sieve with a sieve diameter of 8mm, and the undersieve is used as feed and continuously fed into the cold decomposition crystallizer by a continuous screw feeding system. The feeding rate of high-sodium potassium salt ore is 2.66kg / h, and the MgCl in the circulating liquid 2 The mass percent concentration is 24%, the residence time of the crystallizer is 3.50 hours, the operating temperature is 35°C, the stirring speed of the propulsion type stirring paddle is 400rpm, and the large particle potassium chloride product is obtained in the crystallizer.

[0048] (2) The potassium chloride fine crystal product obtained at the top of the crystallizer in step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com