Method for starting half short-cut nitrification technology

A semi-short-cut nitrification and process technology, applied in the start-up field of the semi-short-cut nitrification process, can solve the problem of slow enrichment of ammonia oxidizing bacteria, and achieve the effects of good treatment, stable operation, and high ammonia nitrogen conversion load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

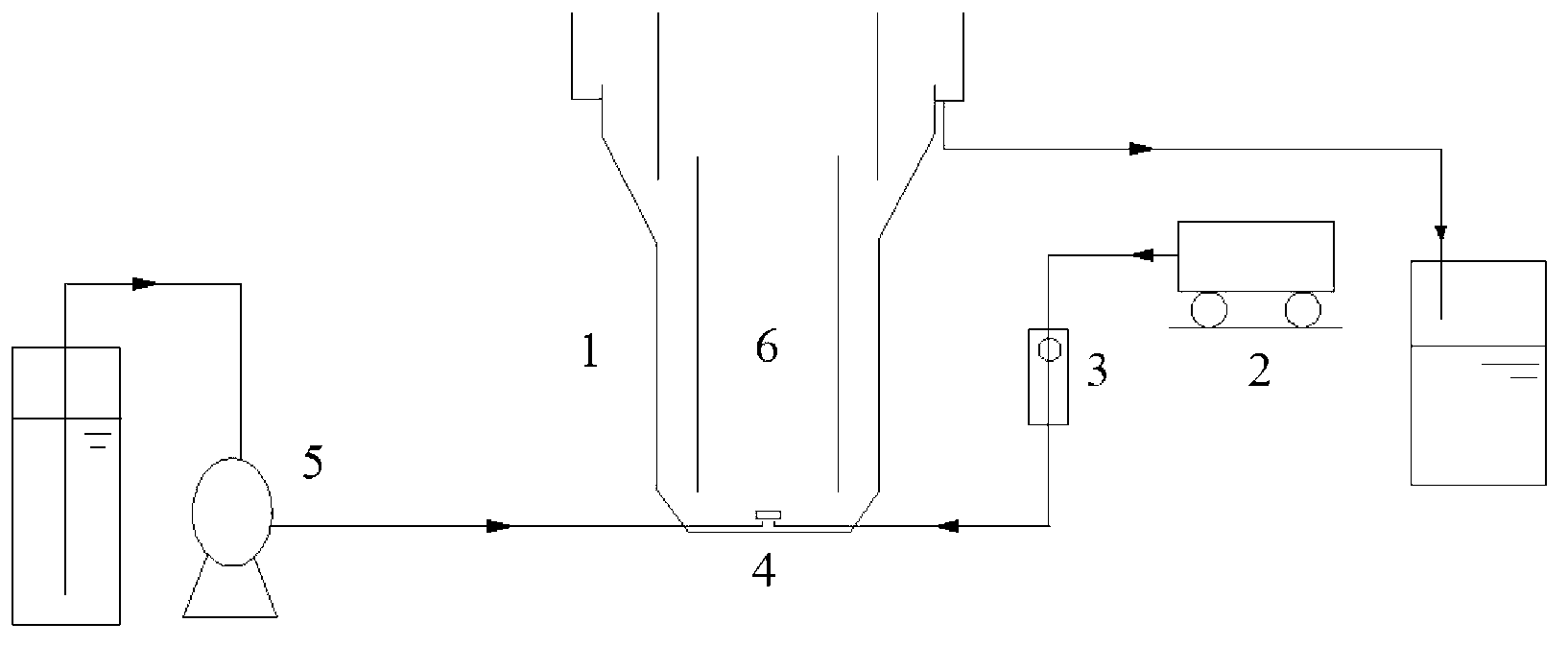

[0015] refer to figure 1 The bottom of the reactor body 1 is equipped with an air inlet and a water inlet, the air passes through the air compressor 2 and the flow rate is controlled by the air flow meter 3, and is introduced into the bottom of the reactor through the microporous gas distributor 4, and the ammonia nitrogen wastewater is collected by the reactor. The peristaltic pump 5 is pumped into the upflow zone 6 from the water inlet at the bottom. The specific steps for starting the semi-short-cut nitrification process are as follows: first, inoculate the aerobic activated sludge into the air-lift internal loop reactor with an effective volume of 3.8 L, and inoculate the sewage The mud concentration is 10g / L, and the simulated wastewater containing ammonia (the initial concentration of ammonia nitrogen is 70mg / L) is used as the reactor feed water, the water temperature of the reactor is maintained at 30°C, the dissolved oxygen concentration in the reactor is 3.0mg / L, and t...

Embodiment 2

[0018] refer to figure 1 , This embodiment adopts the reactor device identical with embodiment 1. The specific steps for the start-up of the semi-short-cut nitrification process are as follows: first, aerobic activated sludge was inoculated into an air-lift internal loop reactor with an effective volume of 3.8 L, the concentration of the inoculated sludge was 15 g / L, and simulated wastewater containing ammonia (ammonia nitrogen The initial concentration is 84mg / L) as the reactor feed water, the reactor water temperature is maintained at 35°C, the dissolved oxygen concentration in the reactor is 4.0mg / L, the hydraulic retention time is 24h, and the mass ratio of alkalinity to ammonia nitrogen in the feed water is 7.14:1, monitor the concentration of ammonia nitrogen in the effluent in real time, and increase the concentration of ammonia nitrogen in the influent when the conversion rate of ammonia nitrogen is greater than 80%; the method for increasing the concentration of ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com