Alcohol production method by taking sugariness raw material as fermentation substrate

A production method and sugar technology, applied in the field of biomass liquid fuel processing, can solve the problems of large area of waste water treatment projects, high waste water treatment costs, hidden dangers of environmental pollution, etc., so as to achieve water-saving production and eliminate environmental pollution. Hidden dangers and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

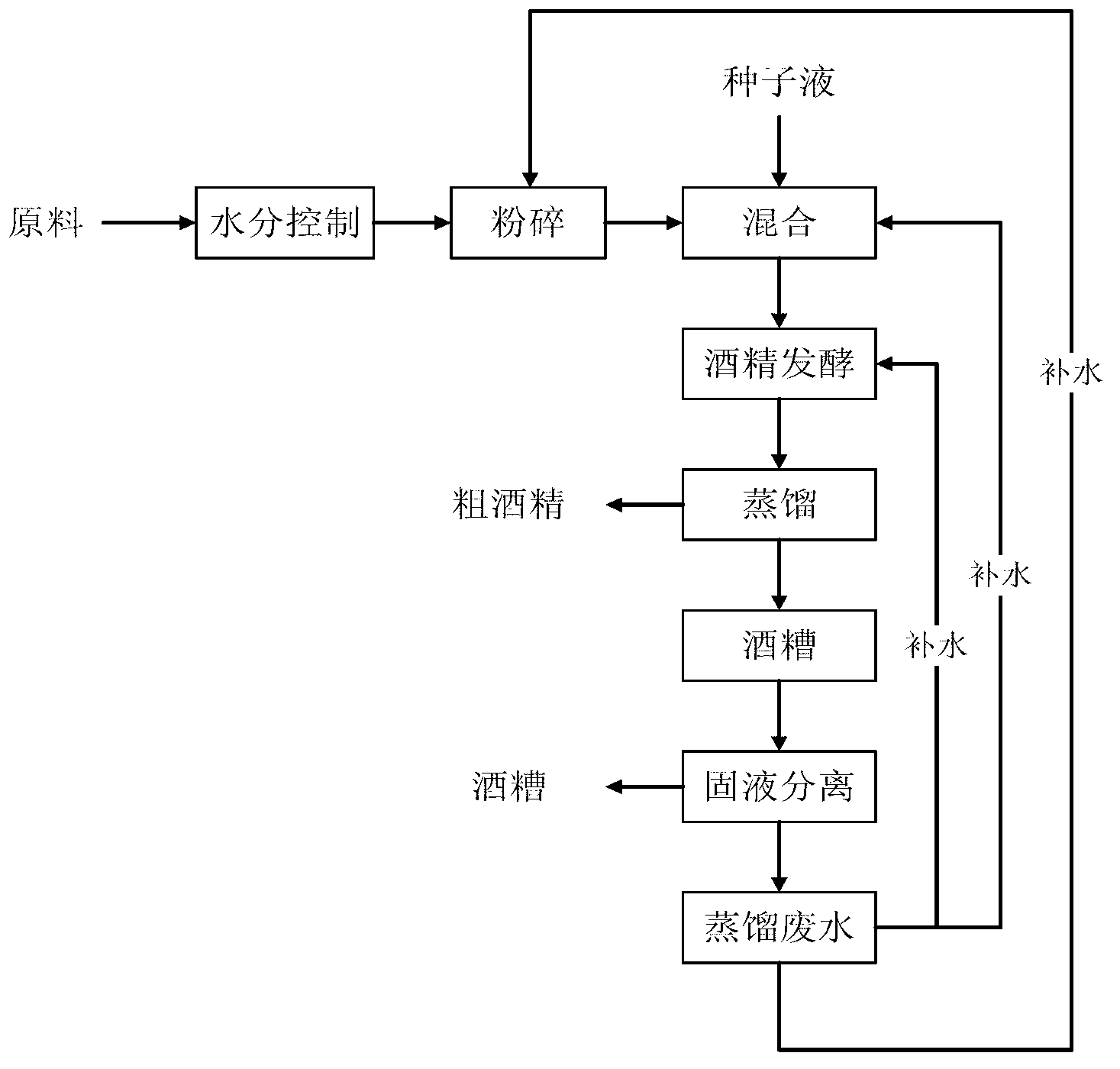

Method used

Image

Examples

Embodiment 1

[0026] A kind of alcohol production method using sugary material as fermentation substrate, adopts following steps:

[0027] (1) Raw material storage: Take 16 tons of sweet sorghum stalks and dry them naturally to control their water content to 20%;

[0028] (2) Crushing: crushing the sweet sorghum stalks with a water content of 20% in (1);

[0029] (3) Moisture adjustment: Add 6 tons of distilled waste water and 4 tons of fresh water to the crushed material obtained in (2), and adjust the moisture content of the material to 70%;

[0030] (4) Alcoholic fermentation: Mix the cultured yeast seed liquid with the material obtained in (3) at a ratio of 15% (v / m) and carry out alcoholic fermentation; the moisture content of the fermented material is 74%, and the fermentation temperature is 28°C, fermentation time 30 hours; (5) Obtaining and using distillation waste water: After alcohol fermentation, after distillation and rectification, 1 ton of fuel ethanol with an ethanol content...

Embodiment 2

[0033] A kind of alcohol production method using sugary material as fermentation substrate, adopts following steps:

[0034] (1) Material moisture control: take 8 tons of sweet sorghum stalks and 8 tons of sugarcane, and control their moisture content to remain unchanged;

[0035] (2) Pulverization: Add 7.25 tons of distillation waste liquid and fresh water to the sweet sorghum stalks with a moisture content of 70% in (1), adjust the moisture content of the pulverized materials to 84.3%, and pulverize;

[0036] (3) Alcoholic fermentation: Mix 1.5 tons of cultured yeast seed liquid with the material obtained in (3) and carry out alcoholic fermentation; the moisture content of the fermented material is 85%, the fermentation temperature is 30°C, and the fermentation time is 16 hours ;

[0037] (4) Acquisition and use of distillation wastewater: After alcoholic fermentation, 1 ton of industrial alcohol with an ethanol content of 99.5% (v / v) and 30 tons of distiller's grains with ...

Embodiment 3

[0040] A kind of alcohol production method using sugary material as fermentation substrate, adopts following steps:

[0041] (1) Material moisture control: Take 16 tons of sugarcane and reduce its moisture content to 50%;

[0042] (2) Crushing: crushing the sugarcane stalks with a water content of 50% in (1);

[0043] (3) Moisture adjustment: Mix 1 ton of the cultured yeast seed liquid and 1.4 tons of distillation waste liquid, and then mix with the pulverized material to adjust the water content of the material to 60%;

[0044] (4) Alcoholic fermentation: send the mixed materials into the fermenter for alcoholic fermentation; the fermentation temperature is 40°C, and the fermentation time is 24 hours;

[0045] (5) Obtaining and using distillation wastewater: After alcoholic fermentation, 1 ton of industrial alcohol with an ethanol content of 99.5% (v / v) and 9.8 tons of distiller's grains with a water content of 74% are obtained after distillation and rectification. The dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com