Electrostatic spinning method for preparing luminous nano composite fiber film containing rare earth polyacid and application of electrostatic spinning method

A nano-composite fiber, rare earth polyacid technology, applied in fiber processing, fluorescence/phosphorescence, material excitation analysis, etc., to achieve wide application prospects, strong operability, and the effect of reducing fluorescence quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

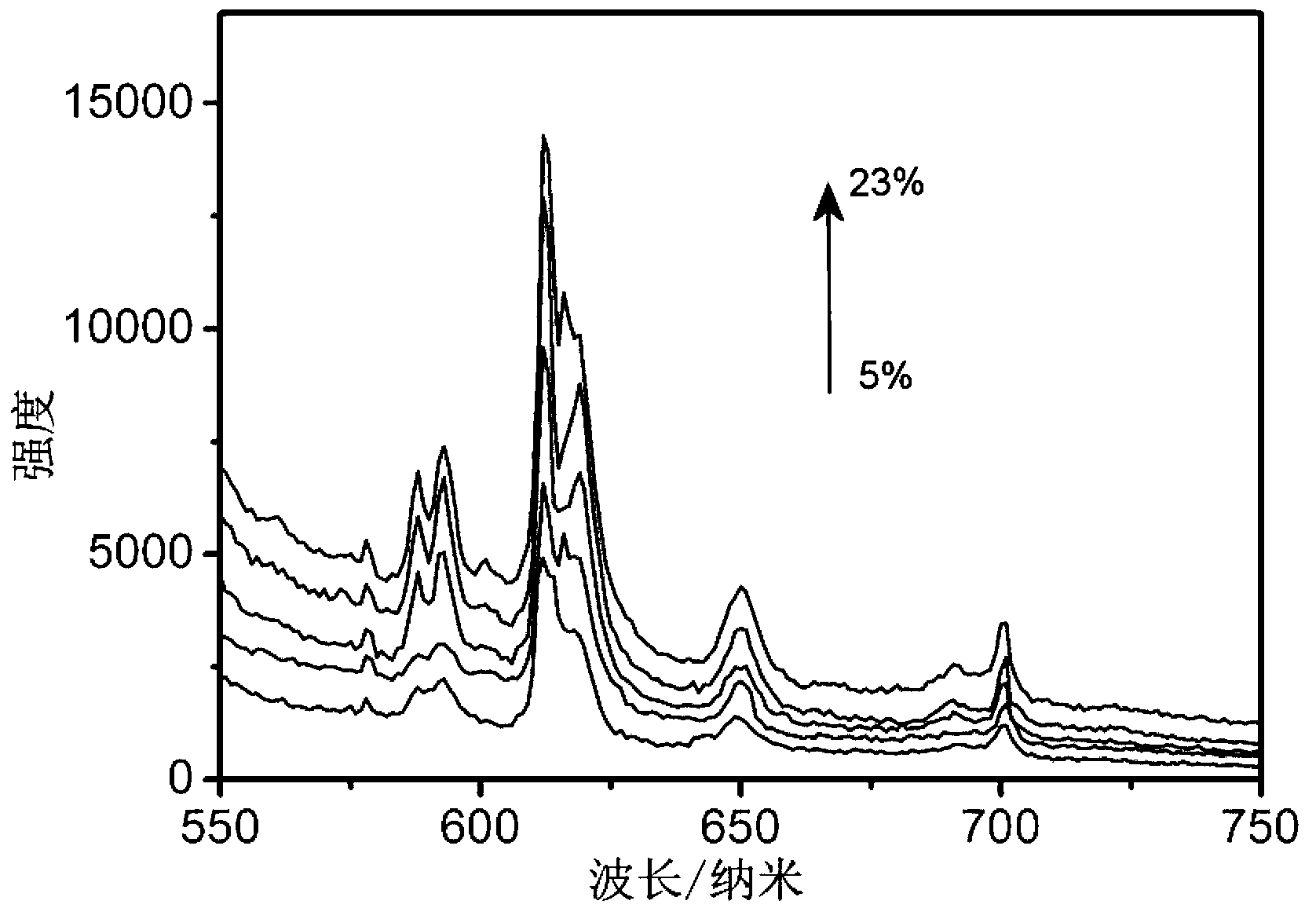

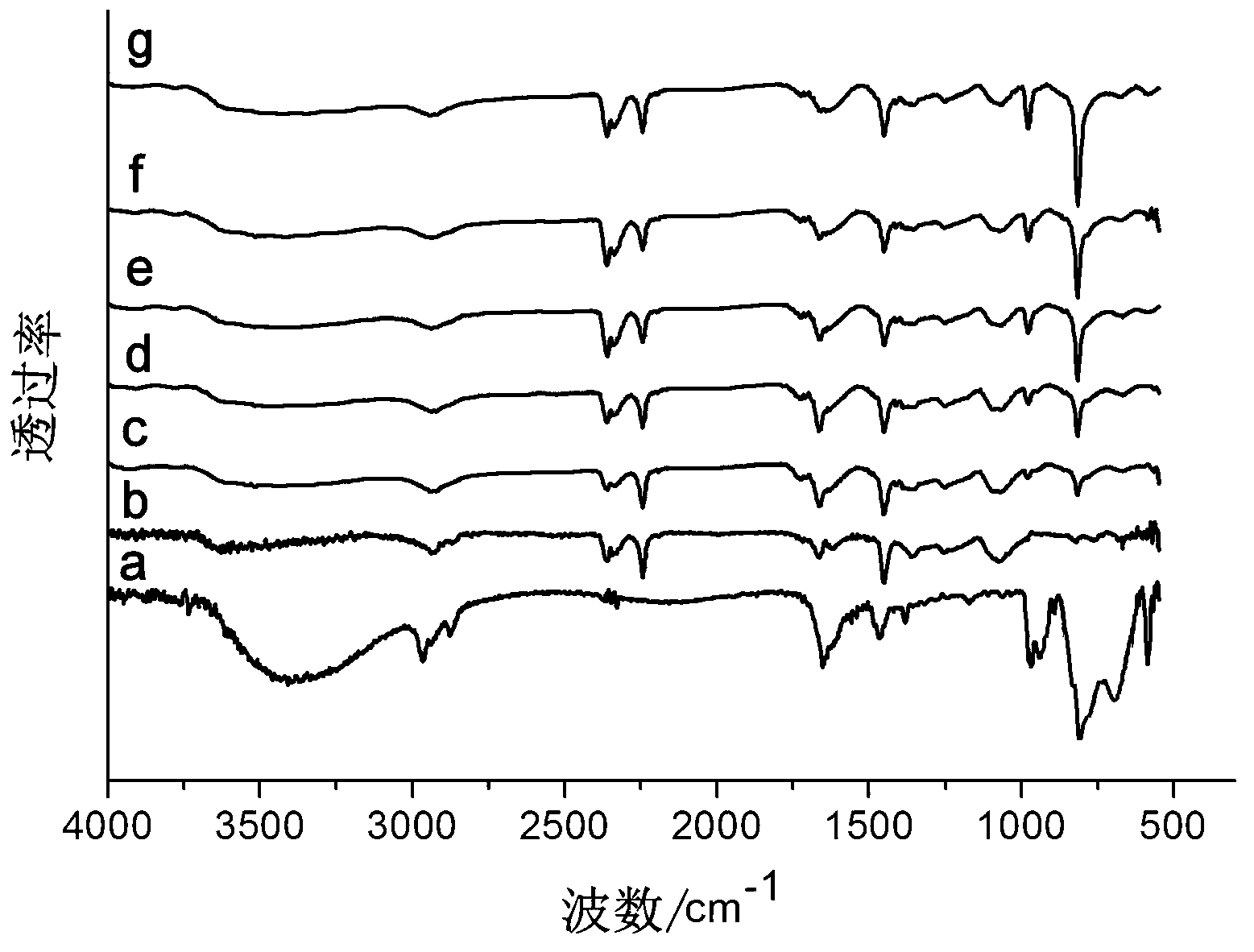

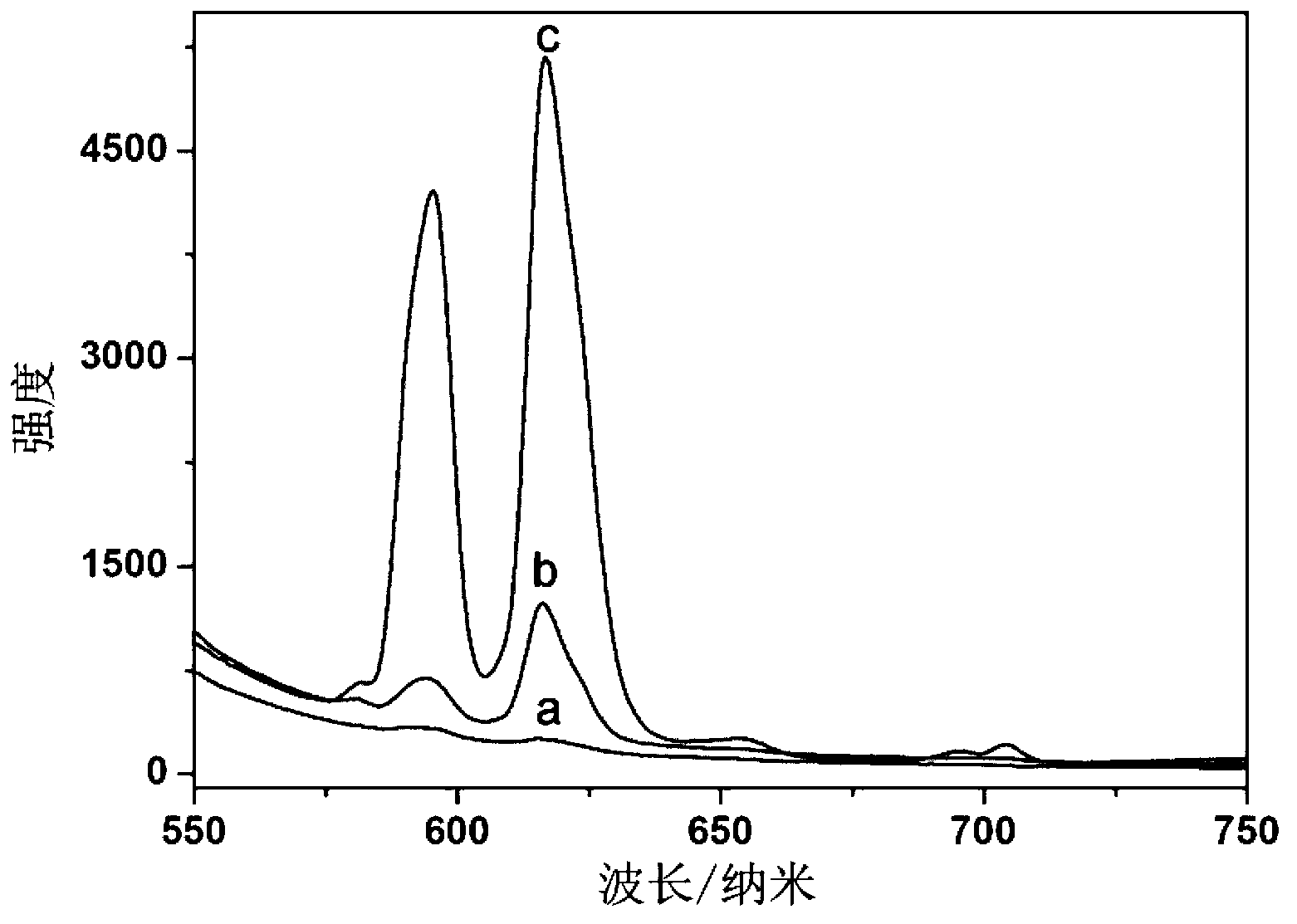

Embodiment 1

[0026] 1. Weigh 23g of dimethylformamide in a 250ml Erlenmeyer flask, then weigh 2g of polyacrylonitrile with a molecular weight of 15,000 and slowly add it under stirring conditions, place the Erlenmeyer flask in an oil bath stirring device, 60 Stir at ℃ for 12h until the polyacrylonitrile is completely dissolved;

[0027] 2. Weigh 100mg of Na 9 wxya 10 o 36 32H 2 O powder, it was added in the polyacrylonitrile solution prepared in step 1, magnetically stirred at room temperature for 6h, until Na 9 wxya 10 o 36 32H 2 The O powder was completely dissolved, and the solution was light yellow, clear and transparent, and EuW was obtained. 10 / Polyacrylonitrile spinning solution;

[0028] 3. Put the spinning solution obtained in step 2 into the glass spinneret of the electrospinning equipment for successive spinning. The inner diameter of the glass spinneret head is 0.6mm, with the aluminum sleeve as the anode and the aluminum foil as the cathode as the receiving plate To ...

Embodiment 2

[0030] The nanocomposite fiber membrane is prepared in the same manner as in Example 1, except that Na 9 wxya 10 o 36 32H 2 O powder is 200mg, the distance from the needle to the receiving plate is 15cm, and the spinning voltage is 17kv. A nanocomposite fiber membrane with a mass ratio of rare earth polyacid to polyacrylonitrile of 0.1 was obtained, and the average diameter of the composite fiber was 198 nm.

Embodiment 3

[0032] The nanocomposite fiber membrane is prepared in the same manner as in Example 1, except that Na 9 wxya 10 o 36 32H 2O powder is 300mg, the distance from the needle to the receiving plate is 20cm, and the spinning voltage is 20kv. A nanocomposite fiber membrane with a mass ratio of rare earth polyacid to polyacrylonitrile of 0.15 was obtained, and the average diameter of the composite fiber was 167 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com