Method for producing bandwidth tunable slow light in polymer filling photonic crystal slot waveguide

A photonic crystal slot and production method technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of limiting the slow light application range of photonic crystal slot waveguides, changing slow light characteristics, and working wavelength drift, and reducing the difficulty of process exploration. 、Various structural parameters, optimizing the effect of slow light characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific structure, principle and slow light characteristic optimization process of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

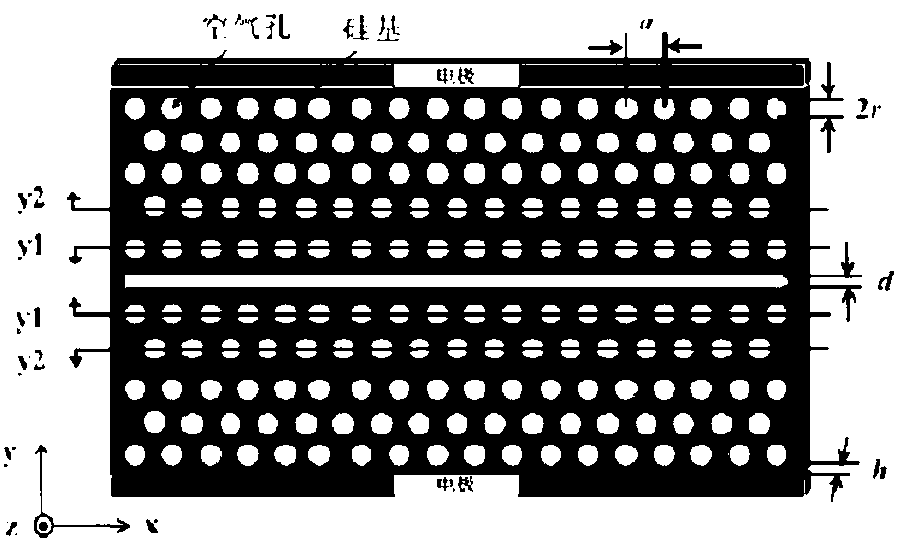

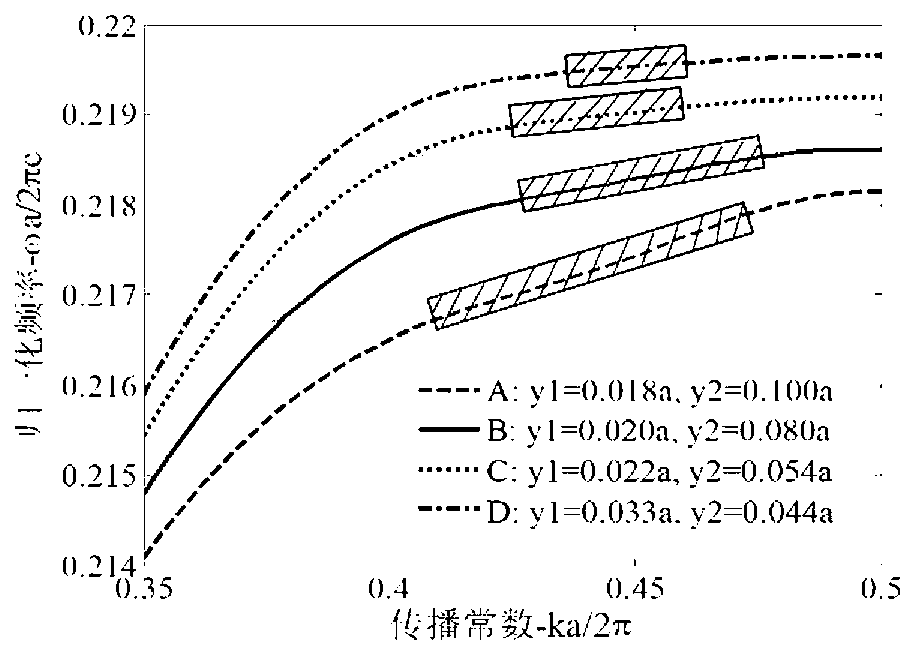

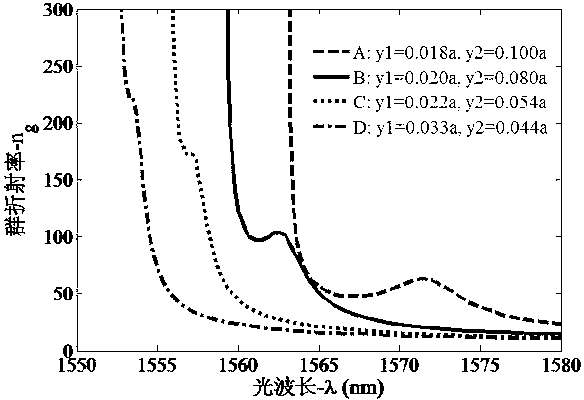

[0027] The present invention proposes a method for generating broadband tunable slow light in a polymer-filled photonic crystal slot waveguide, such as figure 1 Shown is a schematic diagram of the structure of a polymer-filled photonic crystal slot waveguide based on electro-optic modulation. A photonic crystal waveguide with a W1 structure is formed by removing the middle row of air holes along the x direction in an ordinary triangular lattice photonic crystal, and then at the center of the defect Place a row with a width of d =0.32 a The air slots form a photonic crystal slot waveguide structure. in, a =341nm is the photonic crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com