Oxide for semiconductor layer of thin film transistor, sputtering target, and thin-film transistor

A technology of thin film transistors and sputtering targets, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc. It can solve the problems of unstable TFT characteristics, reduced mobility, and increased costs, and achieve switching characteristics and stress resistance. Excellent, small change in threshold voltage, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

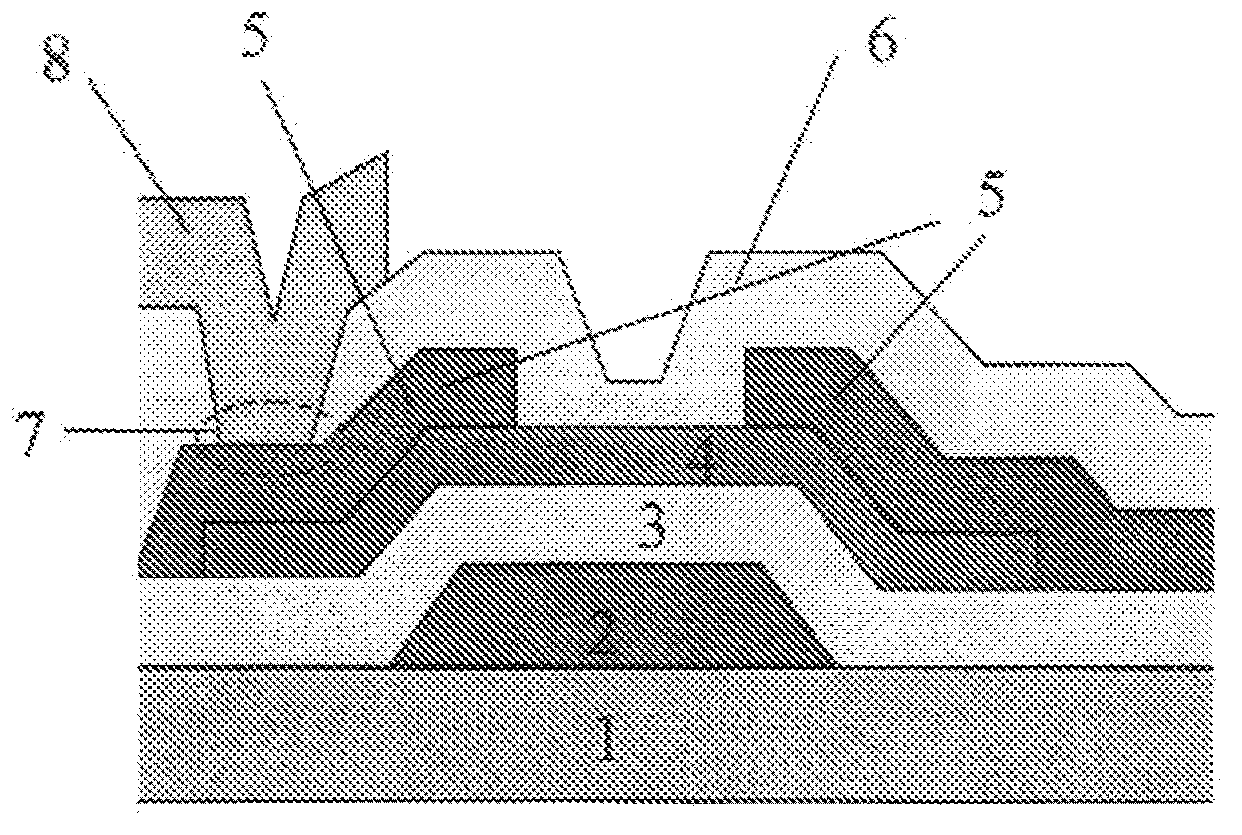

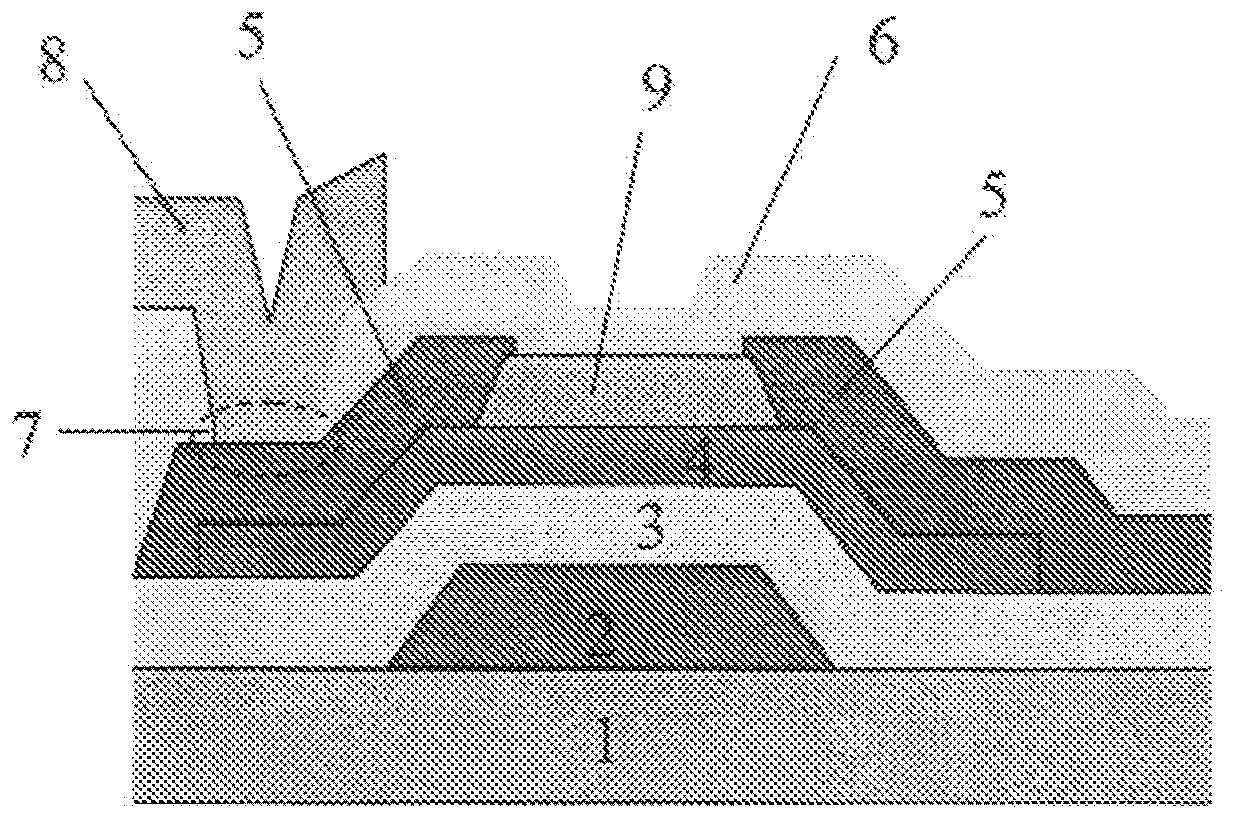

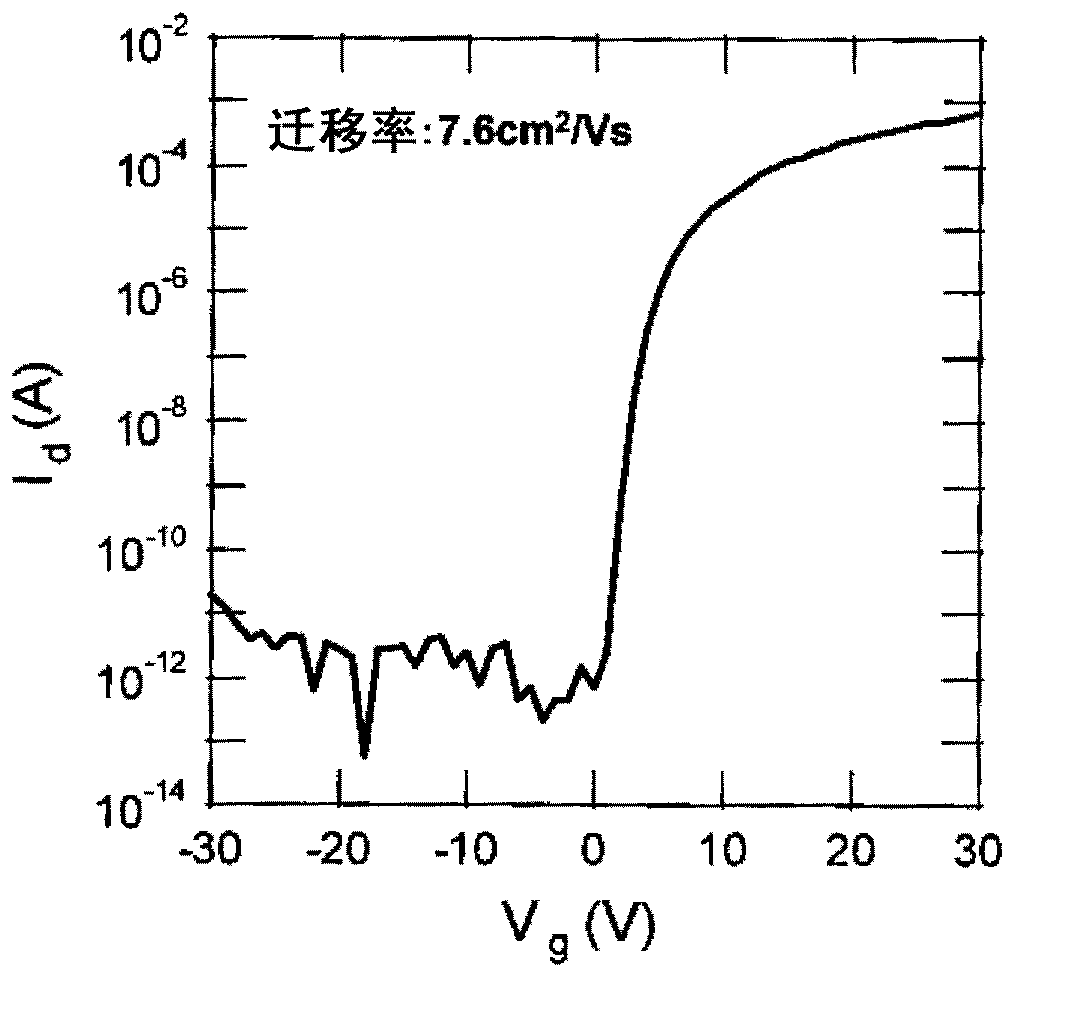

[0083] Based on the above method, the production figure 1 Each characteristic of the thin film transistor (TFT) shown in was evaluated.

[0084] First, on a glass substrate (EAGLE2000 manufactured by Corning, 100mm in diameter x 0.7mm in thickness), a 100nm Mo thin film as a gate electrode, and a gate insulating film of SiO 2 (200nm) film formation. The gate electrode was formed by a DC sputtering method using a pure Mo sputtering target. Set the sputtering conditions as follows: room temperature, film forming power density: 3.8W / cm 2 , Air pressure: 2mTorr, Ar gas flow: 20sccm. In addition, the gate insulating film adopts the plasma CVD method, in the carrier gas: SiH 4 with N 2 Mixed gas of O, film forming power: 1.27W / cm 3 , Film forming temperature: film forming under the condition of 320℃. The air pressure at the time of film formation was set to 133Pa.

[0085] Next, oxide thin films having various compositions described in Table 1 described later were formed int...

Embodiment 2

[0142] In this example, the relationship between the density of the oxide semiconductor film and the TFT characteristics was investigated for oxides having the compositions shown in Table 2. Specifically, while measuring the density of the oxide film (thickness: 100 nm) by the following method, TFTs were produced in the same manner as in Example 1 above, and field-effect mobility was measured. In Table 2, the composition (In-Zn-Sn-O) of No. 1 and 2 oxides in Table 2 is the same as No. 2 in Table 1 above; the composition of No. 3 and 4 oxides in Table 2 (In-Zn-Al-O) is the same as No. 4 in the above table 1; the composition of oxides (In-Zn-Ti-O) of No. 5 and 6 in the table 2 is the same as No. 6 in the above table 1 The composition (In-Zn-La-O) of the oxide of No.7 of Table 2 is the same as No.8 of the above-mentioned Table 1; the composition of the oxide of No.8 of Table 2 (In-Zn-Mg-O ) is the same as No. 9 in the above-mentioned Table 1; the composition (In-Zn-Nb-O) of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com