Flavoniodes processing technology

A kind of processing technology of hollyhock flowers, applied in lighting and heating equipment, heating to dry solid materials, medical preparations containing active ingredients, etc., can solve the problems of high loss of active ingredients, long drying time, browning of color and luster, etc. , to achieve good economic benefits, high degree of hygiene, and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

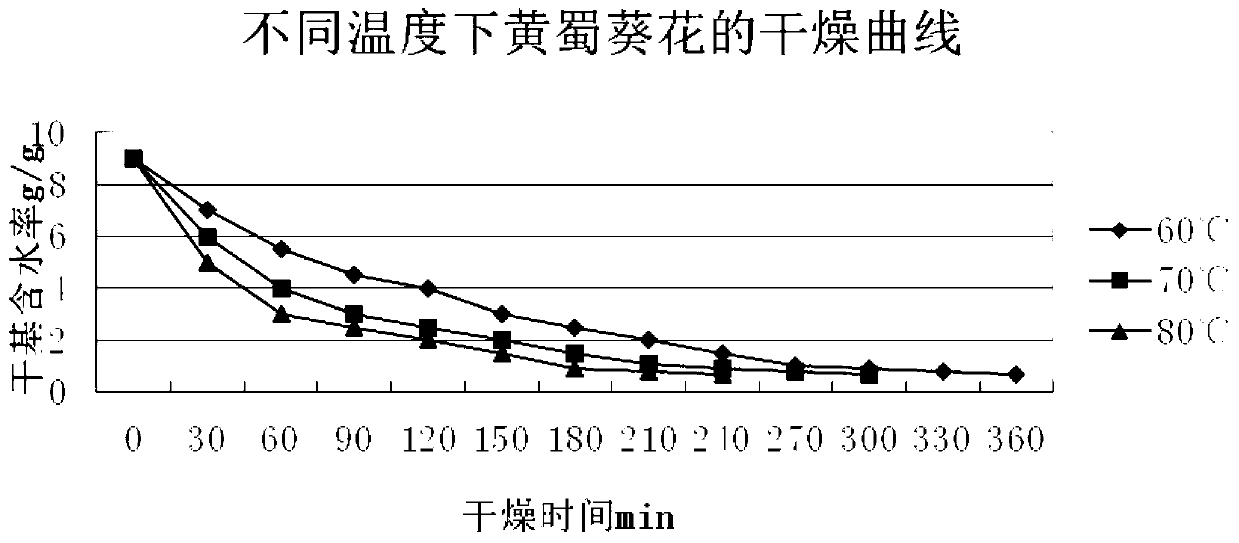

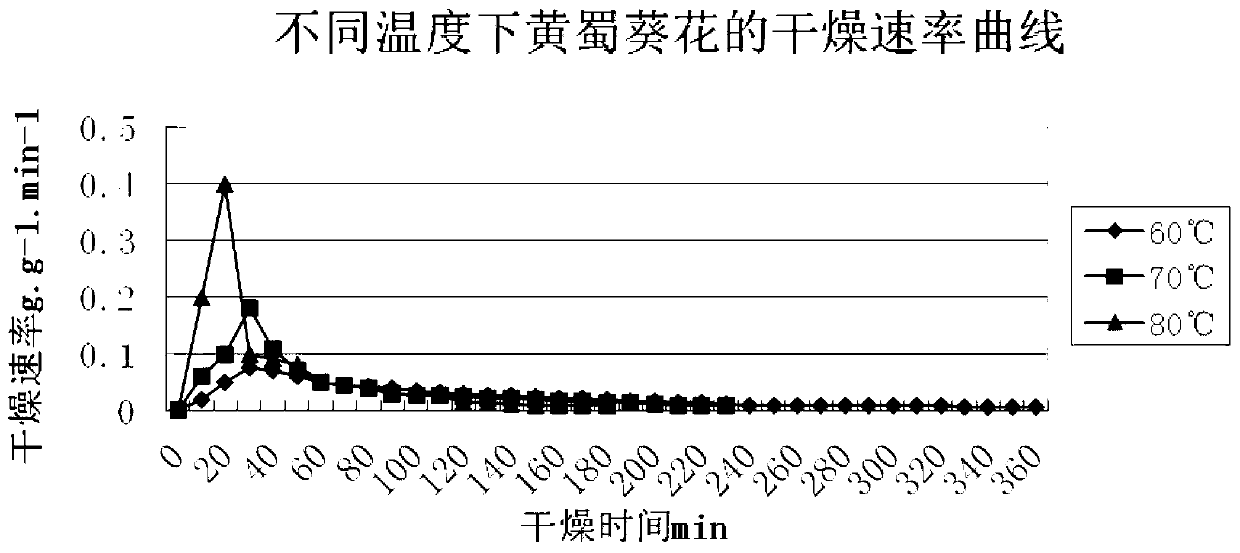

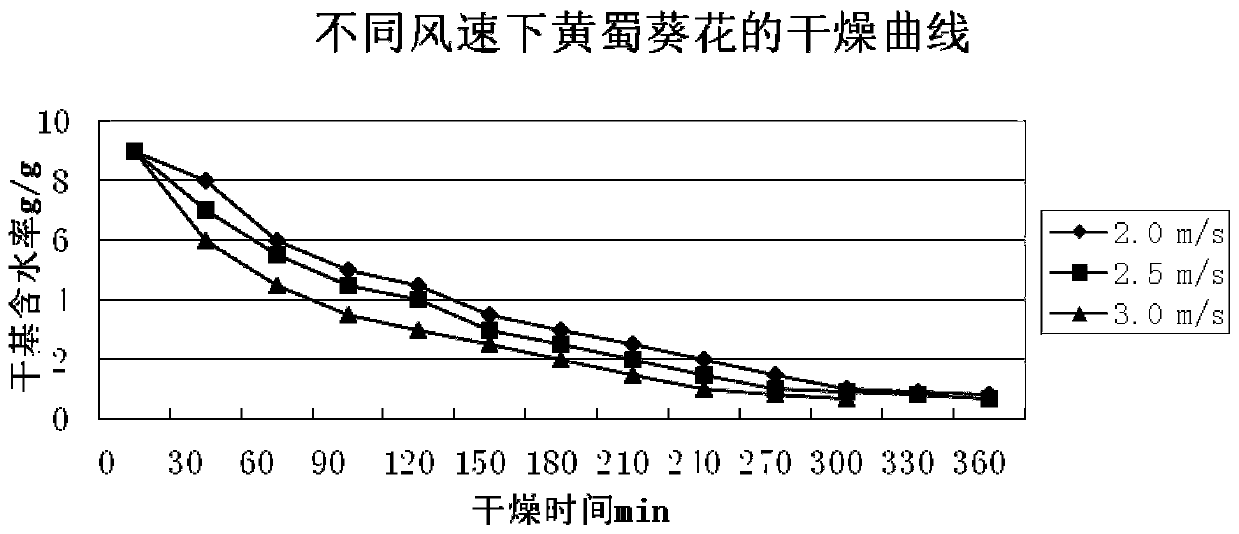

[0042] Pick fresh hollyhock flowers when the flowers are in full bloom in summer and autumn (August-October); remove impurities and rotten petals on the same day; set the temperature at 60°C; wind speed at 2.5m / s, load capacity at 6kg / m 2 ;The hollyhock flowers picked on the same day were dried with hot air within 3 hours of picking, and the drying time was about 6 hours. During the drying process, the real-time quality of the materials was measured regularly, and the moisture content on a dry basis was calculated until the moisture content of the hollyhock flowers was less than 12%.

Embodiment 2

[0044] Pick fresh hollyhock flowers when the flowers are in full bloom in summer and autumn (August-October); remove impurities and rotten petals on the same day; set the temperature at 80°C; wind speed at 2.5m / s, load capacity at 6kg / m 2 ;The hollyhock flowers picked on the same day were dried with hot air within 3 hours of picking, and the drying time was about 3.5 hours. During the drying process, the real-time quality of the materials was measured regularly, and the moisture content on a dry basis was calculated until the moisture content of the hollyhock flowers was less than 12%.

Embodiment 3

[0046] Pick fresh hollyhock flowers when the flowers are in full bloom in summer and autumn (August-October); remove impurities and rotten petals on the same day; set the temperature at 80°C; wind speed at 2.5m / s, load capacity at 4kg / m 2 ;The hollyhock flowers picked on the same day were dried with hot air within 3 hours of picking, and the drying time was about 3.0 hours. During the drying process, the real-time quality of the materials was measured regularly, and the moisture content on a dry basis was calculated until the moisture content of the hollyhock flowers was less than 12%.

[0047] For each of the above embodiments, existing equipment such as GZ-1 drying device, DEY-IV digital anemometer equipment, and BL31 electronic analytical balance can be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com