Preparation method of bismuth phosphate photocatalyst

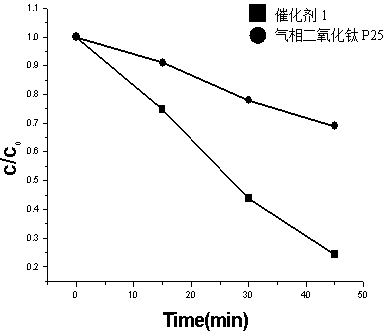

A technology of photocatalyst and bismuth phosphate, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of unsatisfactory catalytic activity of photocatalysts, and achieve low cost and good catalytic performance , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 1 mmol each of EDTA-2Na and bismuth nitrate in water, stir evenly, add nitric acid with a concentration of 65% by mass to adjust the pH to 2, add 1 mmol sodium phosphate, and stir for five minutes to obtain a mixed solution.

[0021] The mixed solution was put into an autoclave, and hydrothermal reaction was carried out at 160° C. for 24 hours. After the hydrothermal reaction, the precipitate was collected by centrifugation, and dried at 60°C for 3 hours to obtain catalyst 1.

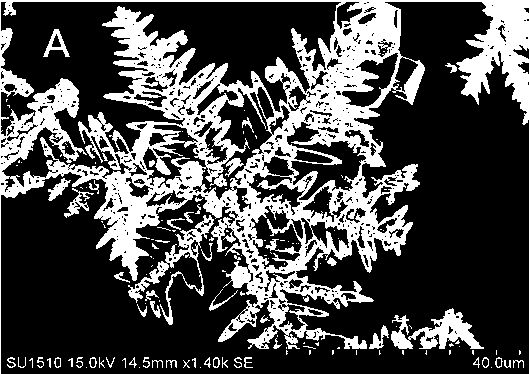

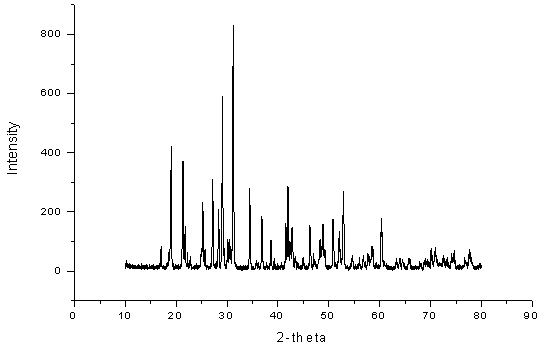

[0022] From figure 1 It can be seen that the crystal morphology of Catalyst 1 is uniform and snowflake-like. From figure 2 It can be seen that catalyst 1 is a pure phase of bismuth phosphate.

Embodiment 2

[0024] Dissolve 1mmol of EDTA-2Na and 0.5mmol of bismuth nitrate in water, stir evenly, add nitric acid with a concentration of 66% by mass to adjust the pH to 3, add 0.5mmol of sodium phosphate, and stir for five minutes to obtain a mixed solution.

[0025] The mixed solution was put into an autoclave, and hydrothermal reaction was carried out at 180° C. for 18 hours. After the hydrothermal reaction, the precipitate was collected by centrifugation, and dried at 80°C for 2 hours to obtain catalyst 2.

[0026] It can be seen from the X-ray diffraction picture of catalyst 2 that catalyst 2 is bismuth phosphate in a pure phase. From the scanning electron microscope image of Catalyst 2, it can be seen that the crystal morphology of Catalyst 2 is uniform and snowflake-like.

Embodiment 3

[0028] Dissolve 1mmol of EDTA-2Na and 0.25mmol of bismuth nitrate in water, stir evenly, add nitric acid with a concentration of 68% by mass to adjust the pH to 2.5, add 0.25mmol of sodium phosphate, and stir for five minutes to obtain a mixed solution.

[0029] The mixed solution was put into an autoclave, and hydrothermal reaction was carried out at 170° C. for 20 hours. After the hydrothermal reaction, the precipitate was collected by centrifugation, and dried at 70°C for 2.5 hours to obtain catalyst 3.

[0030] It can be seen from the X-ray diffraction picture of catalyst 3 that catalyst 3 is bismuth phosphate in a pure phase. From the scanning electron microscope image of Catalyst 3, it can be seen that the crystal morphology of Catalyst 3 is uniform and snowflake-like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com