Formulation of zirconium oxide and aluminum oxide ceramic mirror polishing pellet tablet fixation grinding material

A technology of alumina ceramics and mirror polishing, which is applied in the field of zirconia, which can solve the problems that the surface molding marks cannot be eliminated, there is no targeted polishing process, and high-speed grinding cannot be performed, and the processing effect is remarkable and the surface shape is not easy to change. , the effect of small loss

Active Publication Date: 2013-09-04

衢州飞瑞特种陶瓷有限公司

View PDF8 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this way, the processing efficiency will be low and the processing effect will not be obvious.

At the same time, there will be serious surface scratches, surface molding marks that cannot be eliminated, and other processing problems that affect the mirror effect.

[0006] When conventional fixed abrasives are used for mirror polishing of zirconia and alumina ceramics, high-speed grinding cannot be performed, resulting in low processing efficiency

Poor thermal conductivity also makes it difficult to remove surface scratches, and it is difficult to reflect the mirror effect

The existing general-purpose fixed abrasives are based on diamond grinding, and there is no targeted polishing process. Regardless of the microstructure and special ceramic polishing characteristics, there are relatively large defects and deficiencies. The general purpose of different materials is carried out in the same way. Polishing, which is often lack of efficient production mode

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

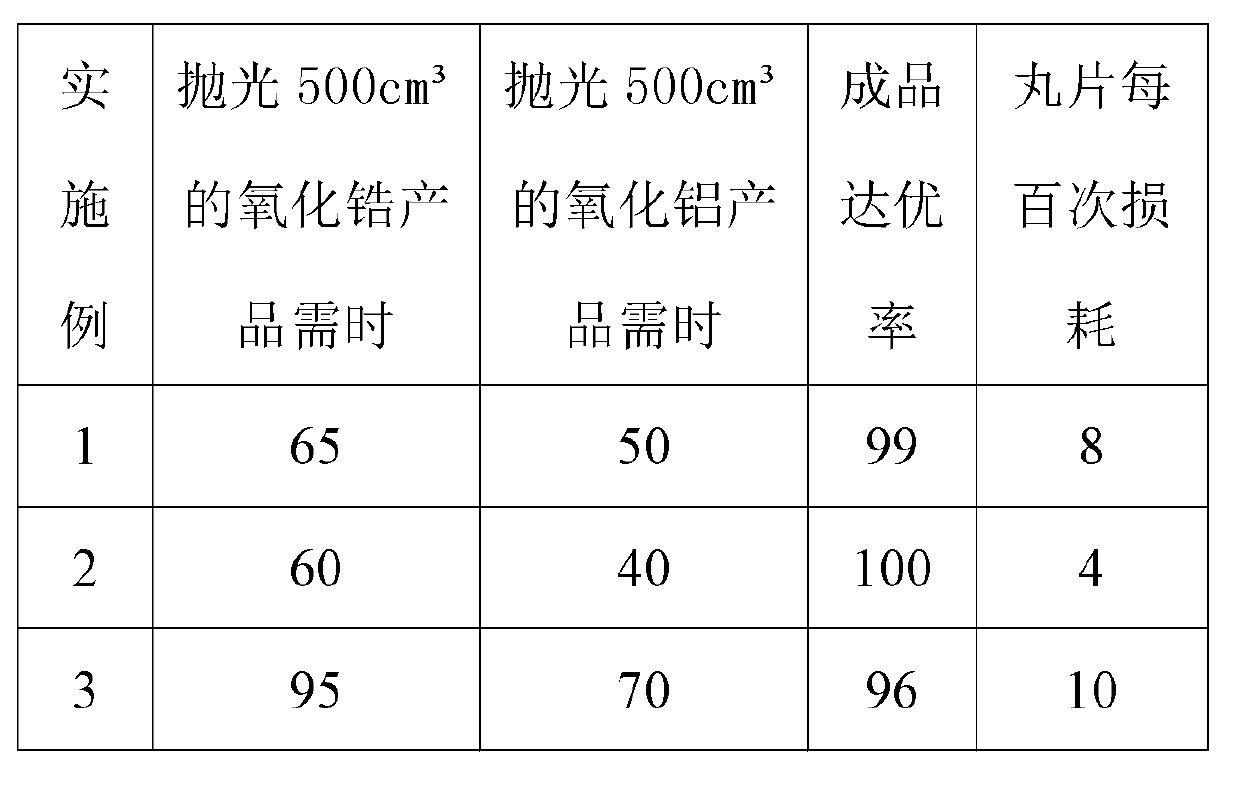

Embodiment 1

[0022] Copper powder 200.0 Diamond powder 42.0

[0023] Resin powder 46.0 Silicon carbide powder 8.0

[0024] Graphite powder 8.0

Embodiment 2

[0026] Copper powder 204.0 Diamond powder 40.0

[0027] Resin powder 44 Silicon carbide powder 8.0

[0028] Graphite powder 8.0

Embodiment 3

[0030] Copper powder 208.0 Diamond powder 42.0

[0031] Resin powder 38.0 Silicon carbide powder 8.0

[0032] Graphite powder 8.0

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a formulation of a zirconium oxide and aluminum oxide ceramic mirror polishing pellet tablet fixation grinding material. A conventional fixation grinding material can not undergo high-speed grinding when being used for zirconium oxide and aluminum oxide ceramic mirror polishing, and therefore machining efficiency is low. The formulation is characterized by comprising the following components of copper powder, diamond powder, resin powder, silicon carbide powder and graphite powder, namely by weight ratio, 50.0-52.0 parts of the copper powder, 10.0-11.5 parts of the diamond powder, 9.5-12.0 parts of the resin powder, 2.0 parts of the silicon carbide powder and 2.0 parts of the graphite powder. According to the formulation, wear resistance is fully considered, surface shape adjustment is small, thermal conductivity is good, water cooling can be easily conducted, and efficiency of mirror polishing is greatly improved. By adopting produced fixation grinding material pellet tablet to machine zirconium oxide products and aluminum oxide products, machining surface quality can be greatly improved, and the surfaces of the products reach 18 nanometers (Ra).

Description

technical field [0001] The invention relates to the field of precision grinding of zirconia and alumina ceramics, in particular to a zirconia, [0002] Formulation of fixed abrasive for alumina ceramic mirror polishing pellets. Background technique [0003] Fixed abrasive high-speed grinding was developed abroad in the 1960s, and my country began to develop it in the 1970s. Fixed abrasive grinding has better solved most of the deficiencies in the traditional slow grinding of loose abrasives. Its biggest feature is that it can significantly improve the grinding efficiency, but the low processing efficiency is the biggest obstacle that restricts the wide application of traditional grinding. Therefore, high-speed grinding with fixed abrasives has attracted people's attention since the emergence of high-speed grinding with fixed abrasives. [0004] In order to better improve the grinding effect of fixed abrasives and improve the quality of pellets, Ju'ichi Ikeno and others fro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24D3/28B24D13/00B24B29/02

Inventor 许庆华曾辉陈蓓

Owner 衢州飞瑞特种陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com