Synthetic method of cooling agent N-, 2, 3-trimethyl-2-isopropyl butyrylamide

A technology of isopropyl butyramide and a synthesis method is applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., and can solve the problems of complex process, inconsistent with green chemistry, low conversion rate of intermediates, and the like, To achieve the effect of simple process, long-lasting cooling sensation and pure aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

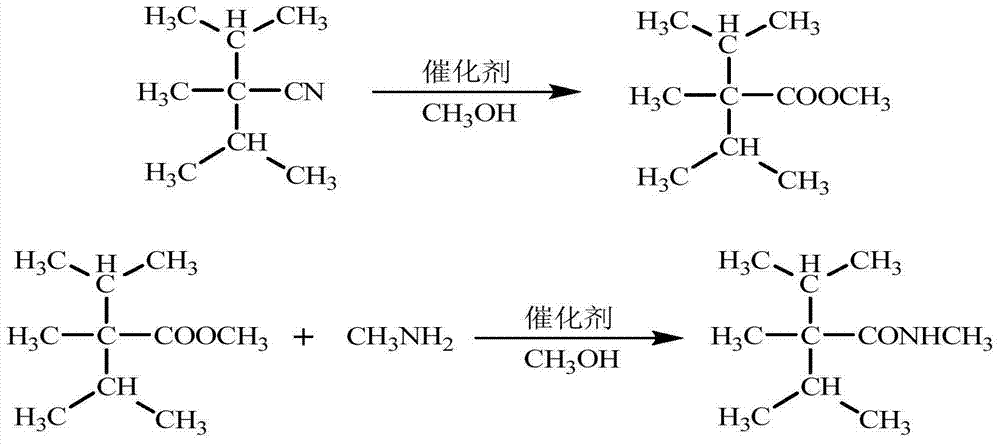

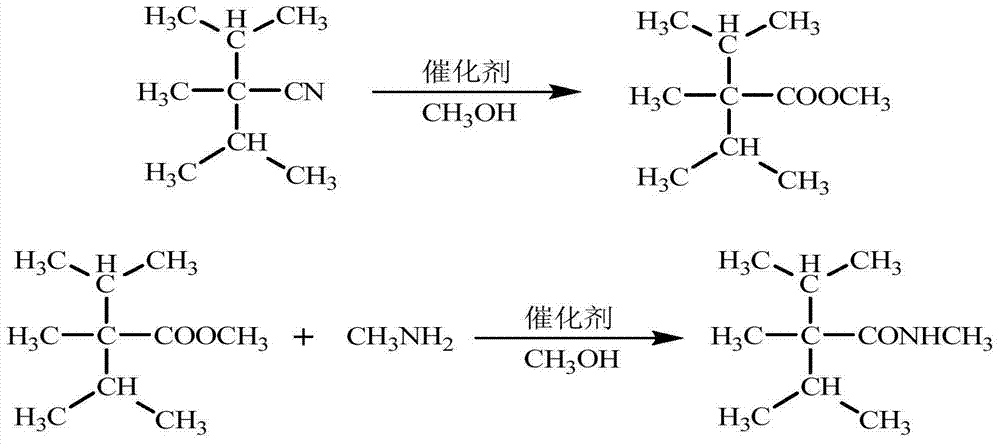

[0016] A kind of cooling agent N, the synthetic method of 2,3-trimethyl-2-isopropyl butanamide is characterized in that, comprises the steps:

[0017] (1) Add the raw materials 2,2-isopropylpropionitrile, alcohol, and acid gas into a 500mL autoclave according to the molar ratio of 1:3~5:3~5, and heat and reflux for 4~10h under stirring conditions , recover excess acid gas and alcohol to obtain the reactant, wash the reactant twice with sodium bicarbonate after cooling, extract with saturated sodium chloride solution, stand still, separate liquid, and dry to obtain 2,3-di Methyl-2-isopropylbutyrate.

[0018] (2) The 2,3-dimethyl-2-isopropyl butyrate reacted in (1) and the amine and the basic catalyst are in a molar ratio of 1:1.5~5:0.04~0.3 respectively Add it into a 500mL autoclave, reflux under stirring for 8 hours, recover the alcohol solution of the amine, add an organic solvent, neutralize to neutral, wash twice with water, separate the liquid, crystallize at a temperatur...

Embodiment 1

[0022] Example 1: Synthesis of methyl 2,3-dimethyl-2-isopropylbutyrate.

[0023] Add 1 mol of 2,2-isopropylpropionitrile and 3 mol of methanol into a 500mL autoclave, and then feed 3 mol of hydrogen chloride gas, and heat to reflux for 4 hours under stirring;

[0024] Cooling and emptying Use cooling methanol to recover excess hydrogen chloride gas (reserve for recycling), and then distill to recover excess methanol (at the same time use cooling ethanol to absorb hydrogen chloride gas, retain for recycling), then wash twice with 50mL saturated sodium bicarbonate, and then Extract with saturated sodium chloride solution, stand still, and obtain the product after liquid separation.

Embodiment 2

[0025] Example 2, the synthesis of 2,3-dimethyl-2-isopropylbutyric acid methyl ester.

[0026] Add 1 mol of 2,2-isopropylpropionitrile and 4 mol of methanol into a 500mL autoclave respectively, then feed 3 mol of hydrogen bromide gas, and heat to reflux for 4 hours under stirring;

[0027] Post-processing is carried out according to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com