Solar cell packaging film

A technology for solar cells and encapsulation films, applied in circuits, adhesives, photovoltaic power generation, etc., can solve the problems of reducing the performance of POE films, affecting the aging resistance of POE films, and no literature reports on solar cell encapsulation films have been found. To achieve the effect of good absorption and utilization, good bonding performance, and improved light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0020] The solar cell encapsulating adhesive film of the present embodiment is made of the following components by weight:

[0021] 100 parts of ethylene-octene copolymer;

[0022] 0.7 parts of tert-butyl peroxy 2-ethylhexyl carbonate as crosslinking curing agent;

[0023] 0.5 parts of trimethylolpropane trimethylmethacrylate as crosslinking curing accelerator;

[0024] 0.5 parts of 3-methacryloxypropyltrimethoxysilane as tackifier;

[0025] 0.3 parts of 2-hydroxy-4-n-octyloxybenzophenone as an ultraviolet absorber.

[0026] After mixing the above-mentioned components uniformly, a solar cell encapsulation adhesive film is prepared according to a conventional method.

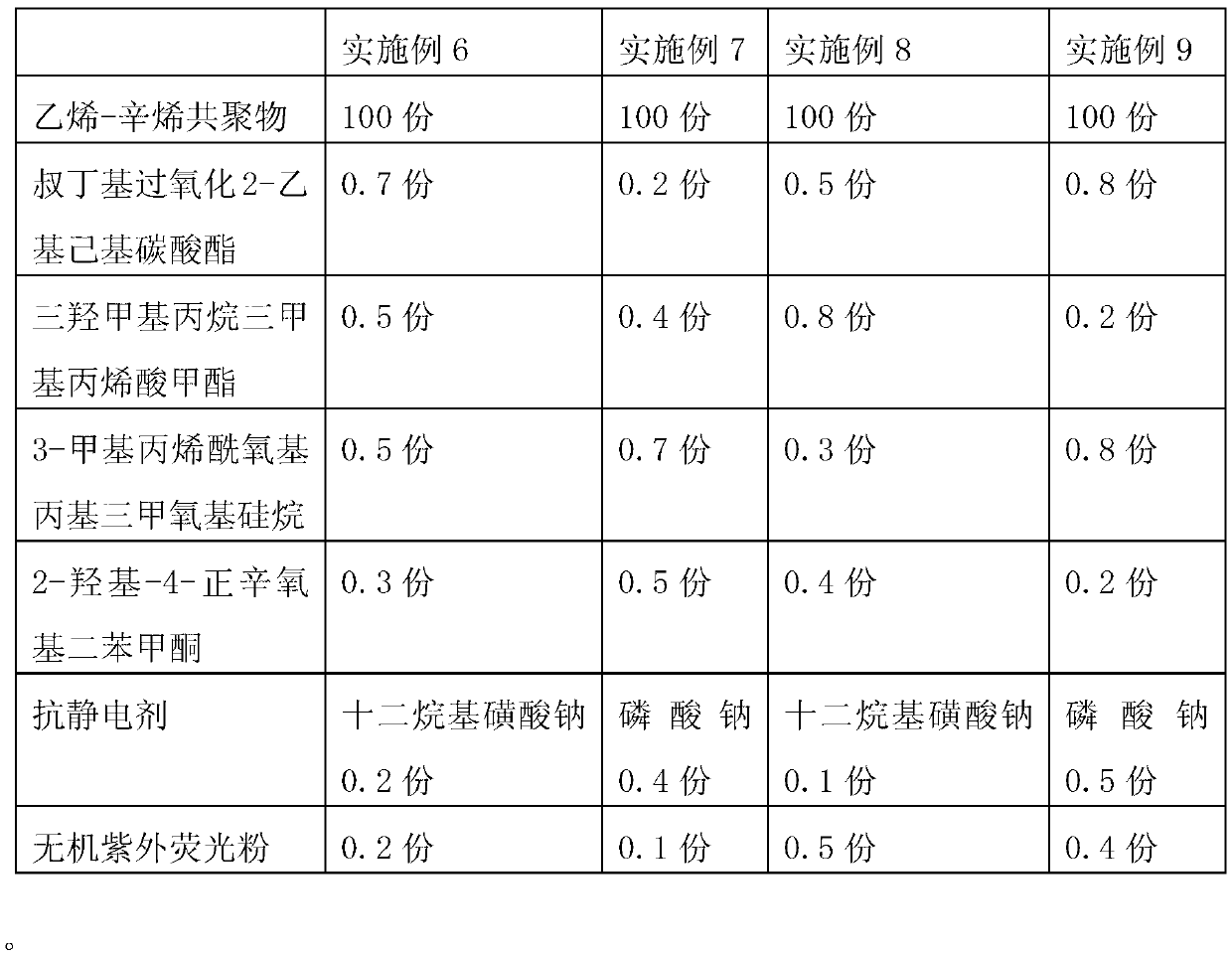

Embodiment 2~ Embodiment 5)

[0028] The solar cell encapsulation film of each embodiment is basically the same as that of Embodiment 1, and the differences are shown in Table 1.

[0029] Table 1

[0030]

[0031] .

Embodiment 6)

[0033] The solar cell encapsulating adhesive film of the present embodiment is made of the following components by weight:

[0034] 100 parts of ethylene-octene copolymer;

[0035] 0.7 parts of tert-butyl peroxy 2-ethylhexyl carbonate as crosslinking curing agent;

[0036] 0.5 parts of trimethylolpropane trimethylmethacrylate as crosslinking curing accelerator;

[0037] 0.5 parts of 3-methacryloxypropyltrimethoxysilane as tackifier;

[0038] 0.3 parts of 2-hydroxyl-4-n-octyloxybenzophenone as ultraviolet absorber;

[0039] 0.2 parts of sodium dodecylsulfonate as antistatic agent;

[0040] 0.2 parts of inorganic ultraviolet fluorescent powder.

[0041] After mixing the above-mentioned components uniformly, a solar cell encapsulation adhesive film is prepared according to a conventional method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com