Antioxidative peptide and preparation method for same

A technology for separation and purification of antioxidant peptides, applied in the field of food biology, can solve problems such as potential safety hazards and waste of protein resources, and achieve the effect of small molecular weight and strong activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of cyanotrophin enzymatic hydrolyzate: mix qingyang meat and water at a mass ratio of 1:1, add 0.5% Papain based on the mass of cyanotrophin, enzymatically hydrolyze at 55 °C for 4 h; sterilize at 95 °C Enzyme for 15 min, centrifuge, and take the supernatant to obtain the enzymatic hydrolyzate of cyanotrophin, the degree of hydrolysis is 16.07±0.21%;

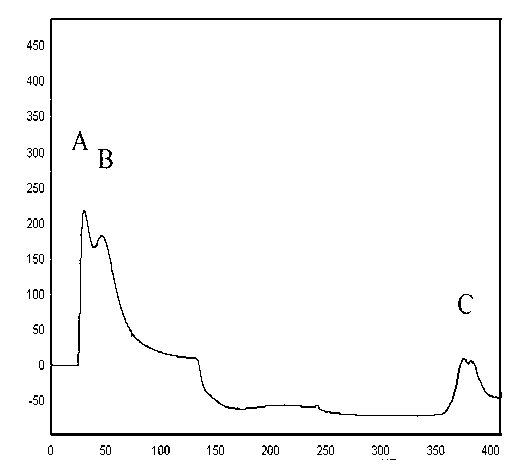

[0033] (2) Separation and purification of antioxidant peptides: pass the Qingyang protein enzymatic hydrolyzate through ultrafiltration membranes with a molecular weight cut-off of 50,000 Da and 1,000 Da, filter out macromolecules, take the permeate, and freeze-dry it into powder; exchange it with weak acid cations The resin Amberlite IRC50 was eluted with 50mM ammonium acetate buffer solution with pH values of 5, 10, and 12 respectively, the flow rate was 4mL / min, and the detection wavelength was 214nm. A total of 3 peaks were collected, and the antioxidant activity of each elution peak was determined. ...

Embodiment 2

[0036] (1) Preparation of cyanotrophin enzymatic hydrolyzate: mix qingyang meat with water at a mass ratio of 1:4, add 0.5% flavor enzyme based on the mass of cyanotrophin, enzymolyze at 50°C for 20 hours; sterilize at 90°C Enzyme for 30 minutes, centrifuge, take the supernatant to obtain the enzymatic hydrolyzate of Qingyang protein, the degree of hydrolysis is 14.21±0.54%;

[0037] (2) Separation and purification of antioxidant peptides: pass the Qingyang protein enzymatic hydrolyzate through ultrafiltration membranes with a molecular weight cut-off of 5000Da and 1000Da, filter out macromolecules, take the permeate, freeze-dry into powder; use weak acidic cation exchange resin Amberlite IRC50 was eluted with 50mM ammonium acetate buffer solution with pH values of 5, 10, and 12 respectively, the flow rate was 6mL / min, and the detection wavelength was 214nm. Three peaks were collected, and the antioxidant activity of each elution peak was measured. The fraction with the high...

Embodiment 3

[0040] Carry out in the same manner as in Embodiment 2, except that papain and flavor enzymes are used to compound to obtain the enzymatic hydrolyzate of cyanotrophin, and the degree of hydrolysis is increased to 18.93±0.12%.

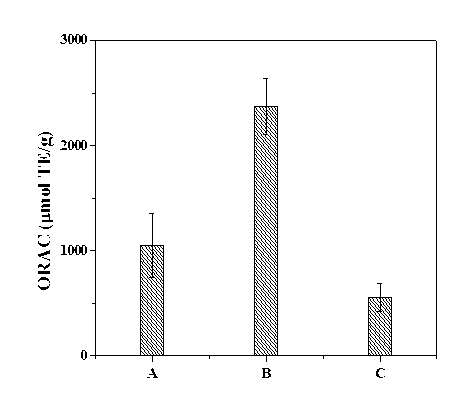

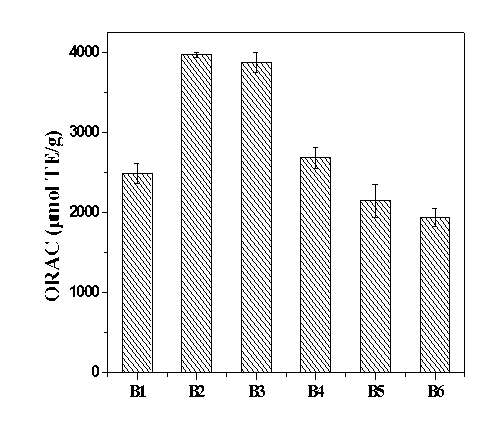

[0041] Figure 1 is the spectrum of antioxidant peptides separated and purified by Amberlite IRC50 ion exchange chromatography. It can be seen from Figure 1 that peak B has the highest antioxidant activity; Figure 2 is the spectrum of antioxidant peptides separated and purified by Sephadex G-15 gel filtration chromatography. 2 It can be seen that the activity of component B2 is the highest, and that of B3 is slightly worse. Figure 3 is a semi-preparative high performance liquid chromatography separation and purification antioxidant peptide map, it can be seen from Figure 3 that components B2-c and B3-a have the highest activity. Fig. 4 is the map of the antioxidant peptides separated and purified by analytical high performance liquid chromatography, iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com