Vertical turbocharger

A turbocharger, vertical technology, applied in the direction of machines/engines, engine components, internal combustion piston engines, etc., can solve the problems of complex control system, complex air flow channel, large flow loss, etc., achieve low noise and improve mechanical efficiency , The effect of small friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

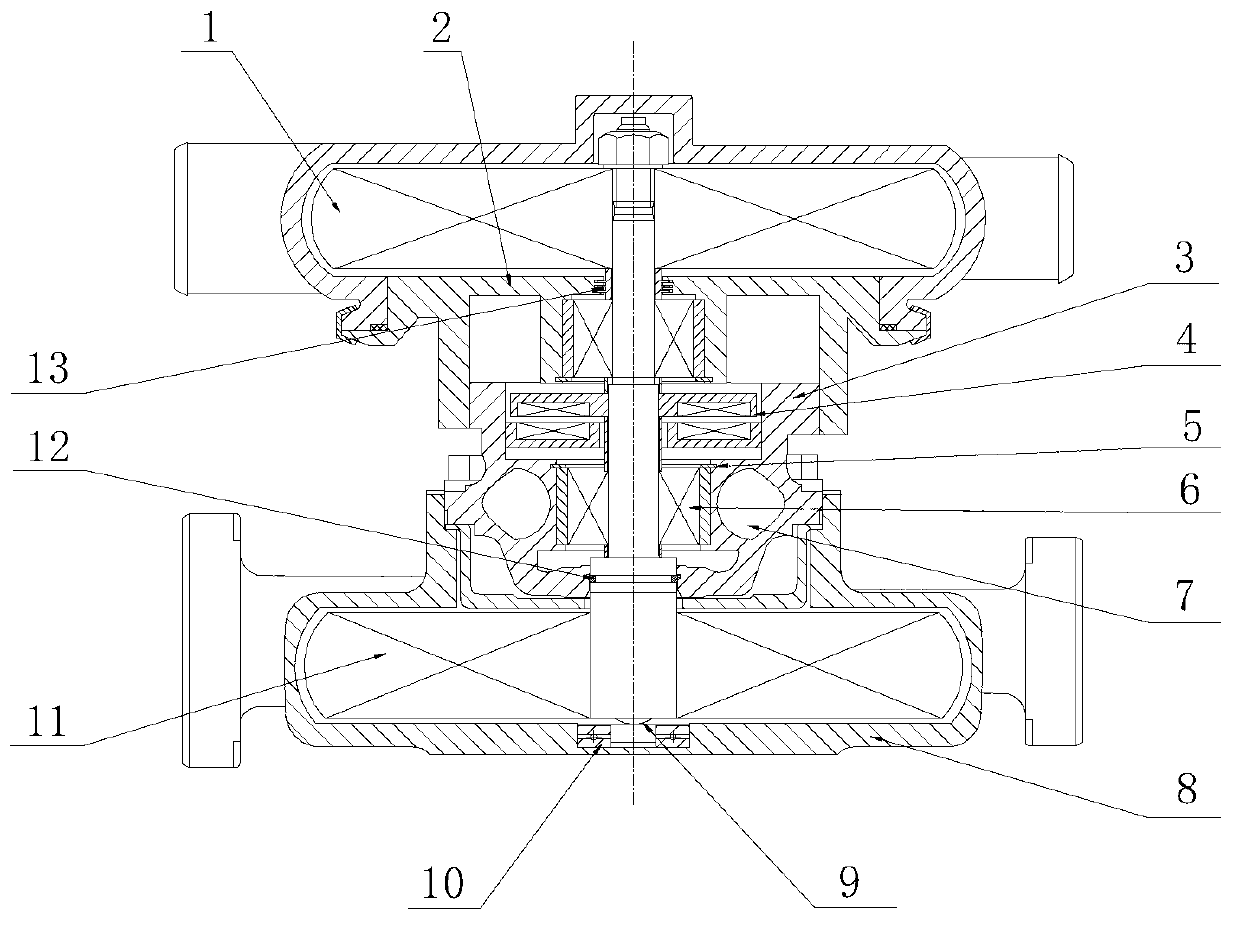

[0034]figure 1 It is a structural diagram of the first embodiment of the vertical turbocharger of the present invention. The non-liquid oil lubricated bearing used in this embodiment is an electromagnetic bearing, including a radial electromagnetic bearing 6 and an axial electromagnetic bearing 4, such as figure 1 shown. The rotor shaft of the vertical turbocharger is arranged vertically to the ground, and the compressor and the turbine are respectively arranged at the upper end and the lower end of the rotor shaft. In the present invention, the rotor shaft is vertically arranged, so the lower end of the rotor shaft and the An axial thrust bearing 10 is provided at the matching place of the turbine casing 8 of the turbine for carrying axial force. Preferably, in order to reduce the friction between the rotor shaft and the axial thrust bearing 10 when it rotates, the top of the lower end of the rotor shaft is provided with a spherical center 9 structure to cooperate with the a...

no. 2 example

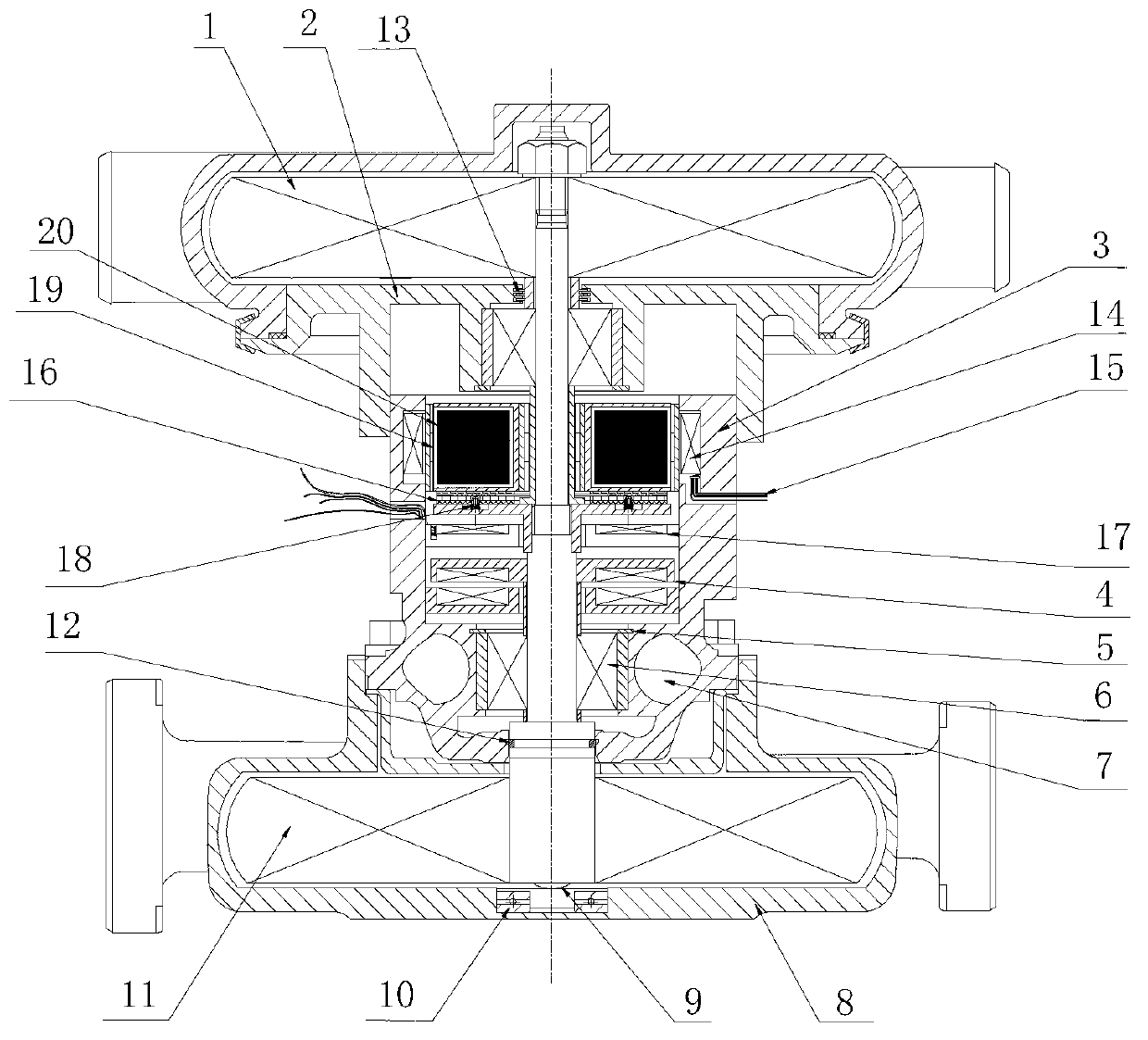

[0036] figure 2 It is a structural diagram of the second embodiment of the vertical turbocharger of the present invention. Such as figure 2 As shown, further, in order to solve the problem of "turbo lag" of the turbocharger, improve the utilization rate of exhaust gas energy, and improve the economical efficiency of the engine, the intermediate body 3 of the vertical turbocharger and the compressed air in this embodiment A motor generator and a clutch device are arranged between the motors, and both the motor generator and the clutch device are arranged around the rotor shaft, and the motor generator can be combined and separated from the rotor shaft through the clutch device. When the engine starts, accelerates or operates at low speed, the motor-generator rotor 20 is combined with the rotor shaft through the clutch device, the motor-generator rotor 20 and the turbine drive the coaxial compressor to rotate together, and the motor-generator acts as a motor to drive the roto...

no. 3 example

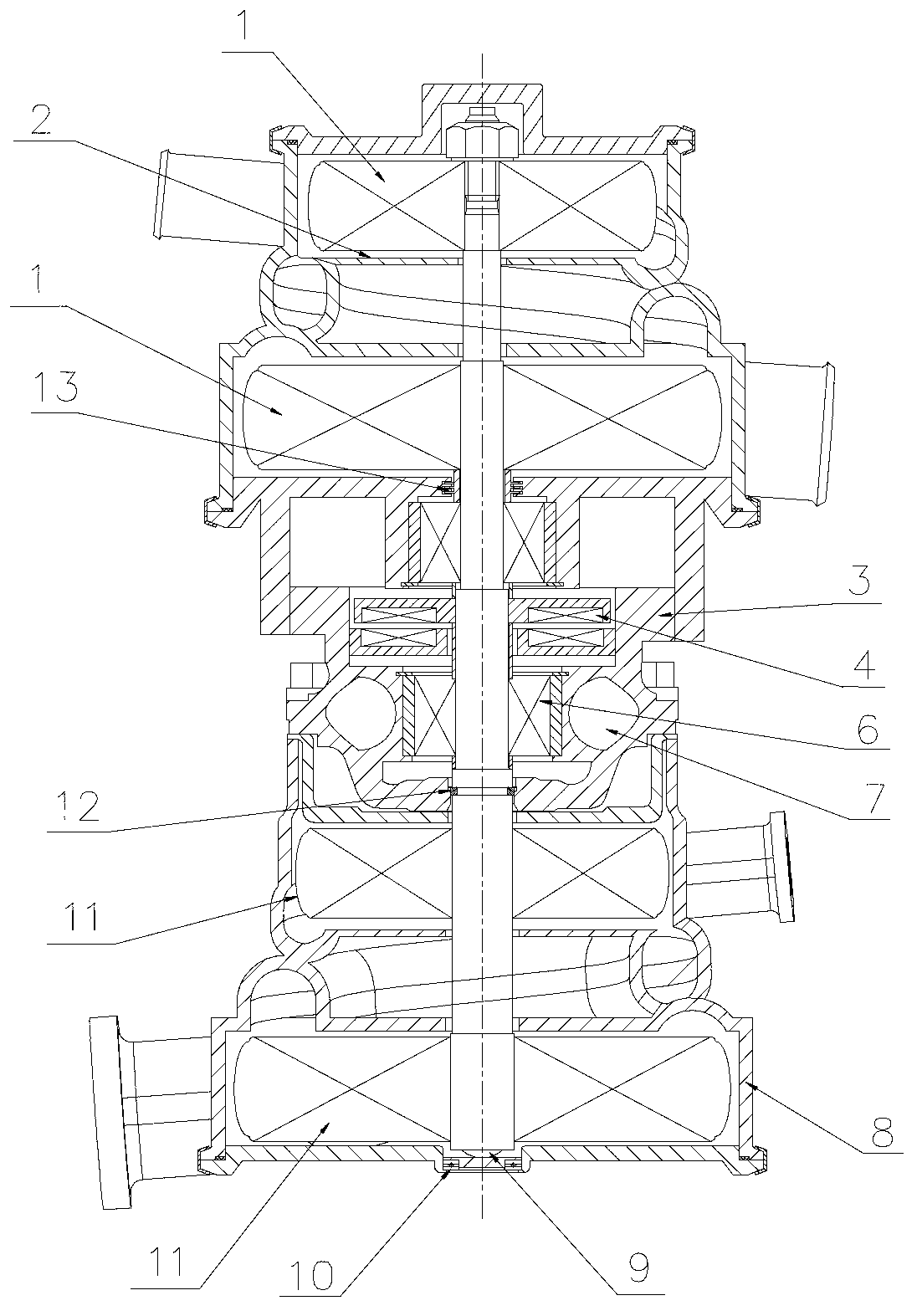

[0039] In the first embodiment and the second embodiment, the compressor and the turbine are respectively a first-stage compressor and a first-stage turbine, and the third embodiment of the present invention is as image 3 shown. In order to improve the utilization efficiency of exhaust gas and improve the working efficiency of the compressor, in this embodiment, the turbine is a two-stage turbine with two turbine wheels 11, and the two turbine wheels 11 are installed on the rotor shaft in sequence, which is relatively Preferably, the two turbine impellers 11 are one large and one small, and the center line of the gas passage in the turbine shell 8 of the second-stage turbine is a quadratic curve or a cubic curve and above curves, and spiral upward or Downward structure, the helix angle is γ, 180°≤γ≤360°, and the cross-section of the flow channel is circular, double pear-shaped or quadratic. The compressor is a two-stage compressor with two compressor impellers 1, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com