Cross position-sensitive anode and method for achieving photon counting integral imaging measurement with cross position-sensitive anode applied

A position-sensitive anode and electron technology, applied in the field of multi-anode detection, can solve the problems of reducing signal pulse transmission speed, charge signal delay, poor real-time signal processing, etc., and achieve the effect of improving time resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

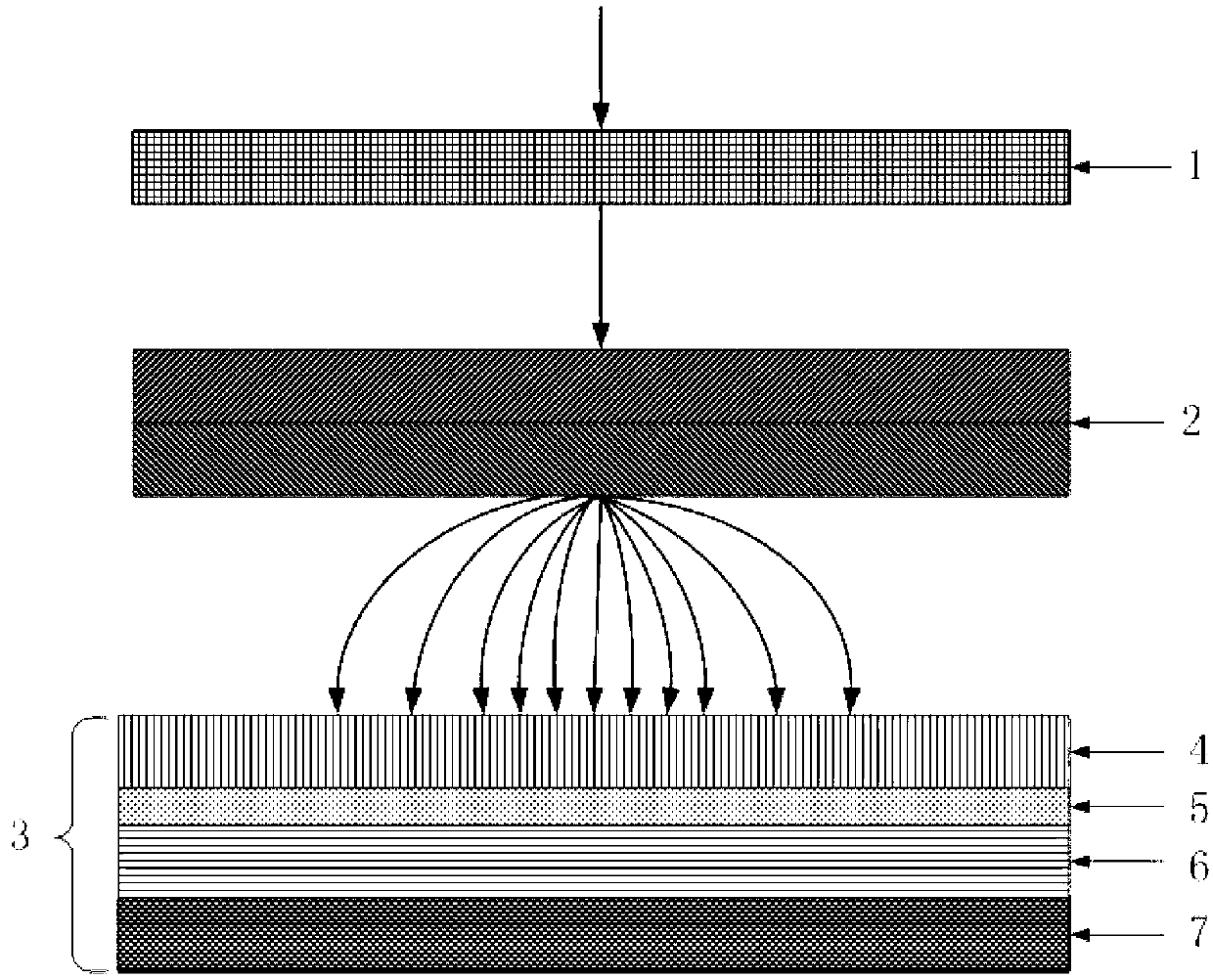

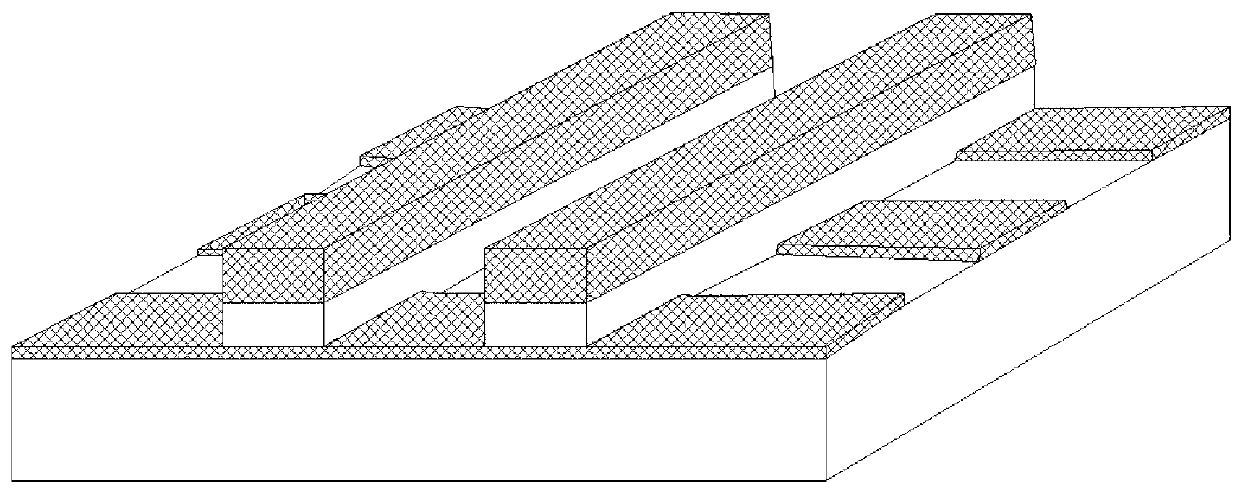

[0041] Such as image 3 Shown is a schematic diagram of the structure of the cross position sensitive anode of the present invention. The cross-position-sensitive anode is designed as upper and lower conductive layers and an insulating layer in the middle by using the principle of charge division. Both the upper conductive layer and the lower conductive layer include a plurality of rectangular conductive strips with the same size. The conductive strips are composed of rectangular insulating strips with the same size and arrangement. The rectangular conductive strips of the upper conductive layer are vertically overlapped on the rectangular conductive strips of the lower conductive layer through the insulating layer; the rectangular conductive strips of the upper conductive layer are parallel to each other in the same plane. , each rectangular conductive strip of the lower conductive layer is parallel to each other in the same plane; the insulating layer corresponds to each rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com