Transverse high-voltage power device with ultralow specific on-conduction resistance and manufacturing method of transverse high-voltage power device

A technology of specific on-resistance and lateral high voltage, applied in the field of semiconductor power devices, can solve problems such as rising on-resistance, and achieve the effect of reducing resistivity, small on-resistance, and reducing on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention provides a horizontal high-voltage power device realized by ion implantation process, which has low process difficulty and strong operability. By selecting different types of substrates and impurities, n-channel and p-channel horizontal high-voltage power devices can be manufactured .

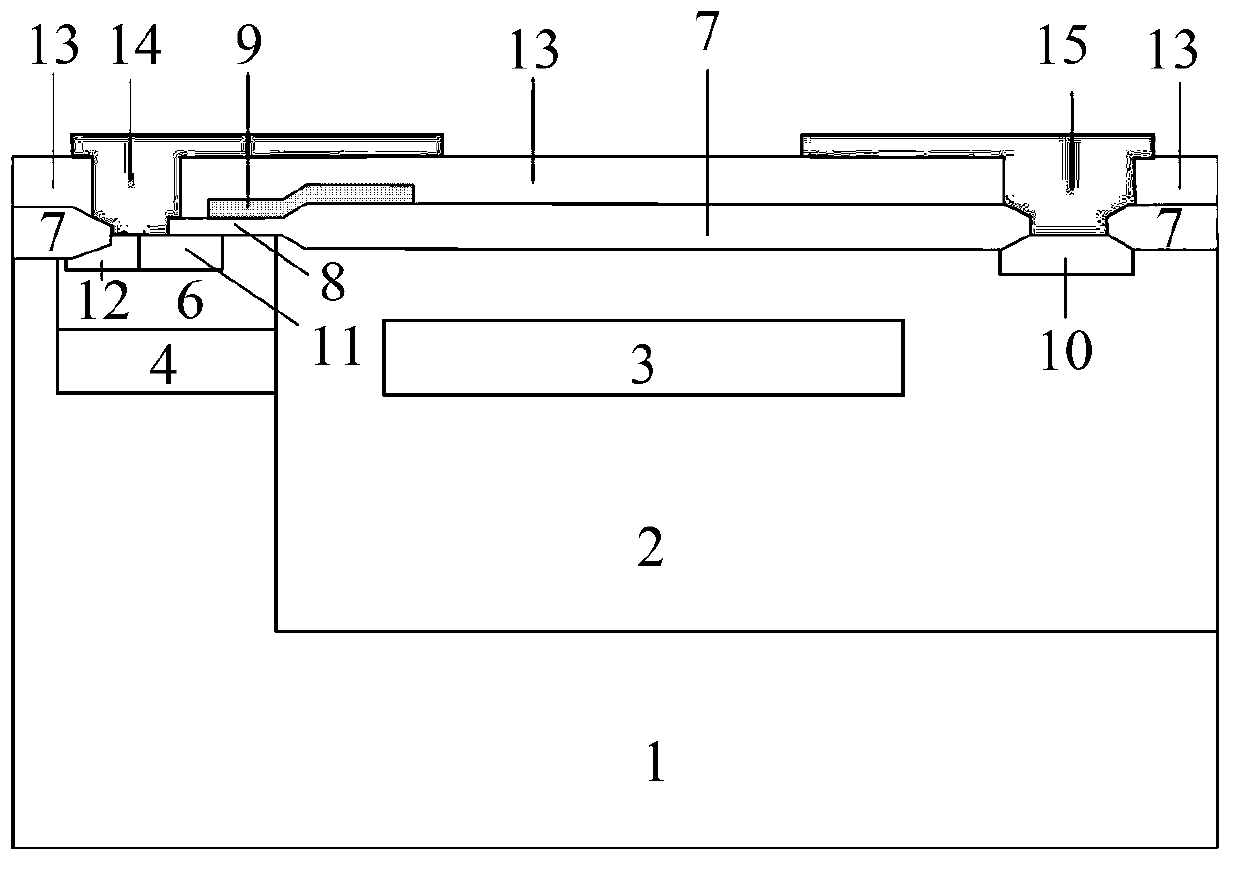

[0036] figure 1 The structure diagram of a traditional lateral high voltage DMOS device with a field drop layer structure is given, including a first conductivity type semiconductor substrate 1, a second conductivity type semiconductor drift region 2, a first conductivity type semiconductor drop field layer 3, and a first conductivity type Semiconductor body region 6, field oxide layer 7, gate oxide layer 8, polysilicon gate electrode 9, second conductivity type semiconductor drain region 10, second conductivity type semiconductor source region 11, body contact region 12, pre-metal dielectric 13, source electrode Metal 14 and drain metal 15.

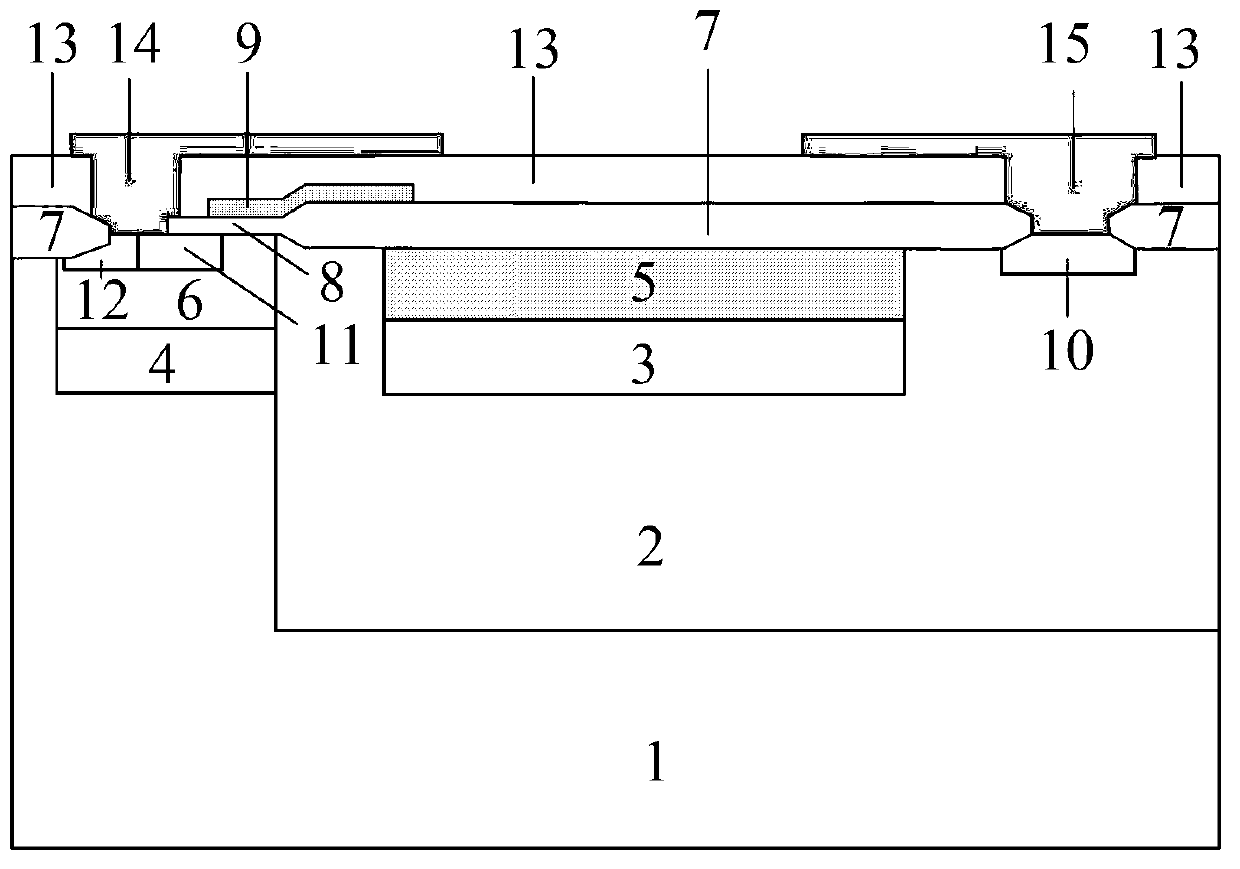

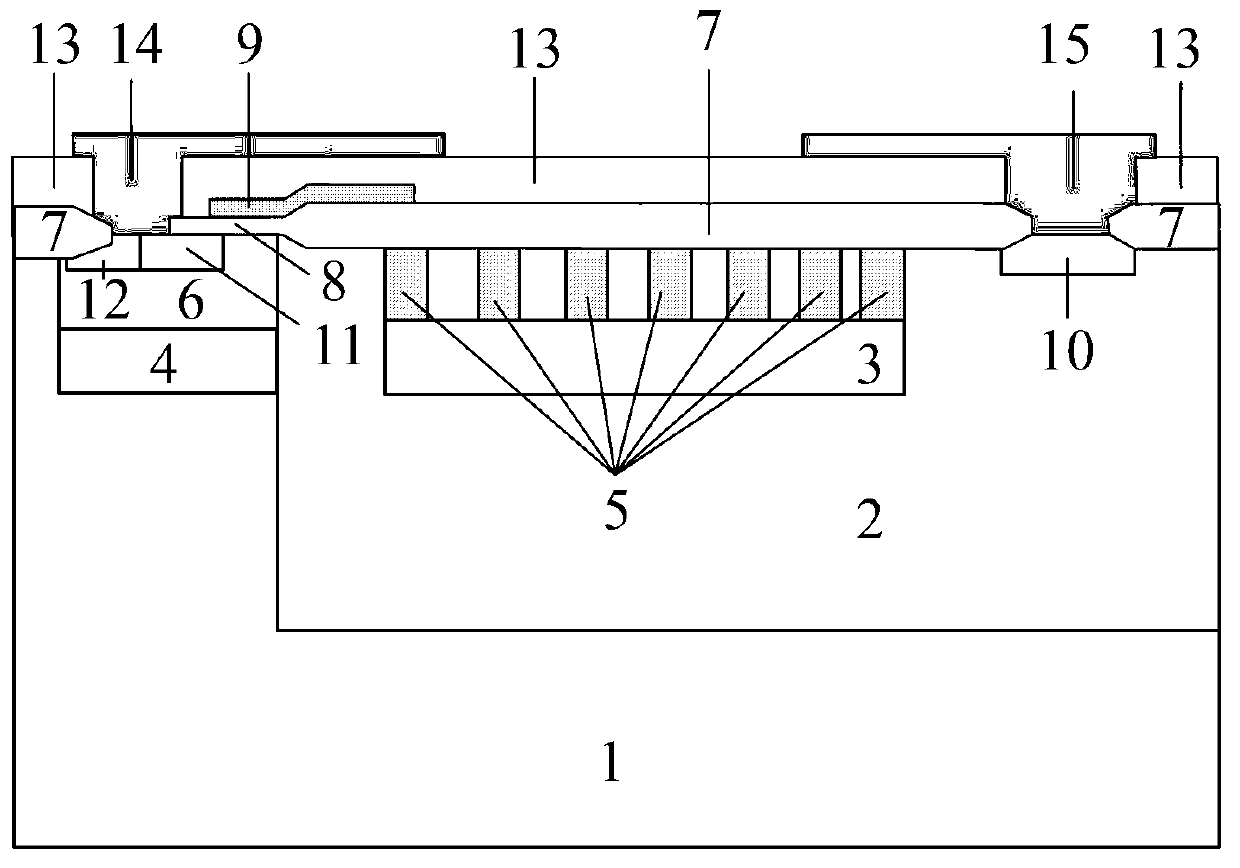

[0037] figure 2 It is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com