A white light organic electroluminescent device

An electroluminescent device, an organic technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of low device efficiency, light color difference, different structure of white light devices, etc., and achieve high color stability and device efficiency. The effect of high and multiple luminescence bands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

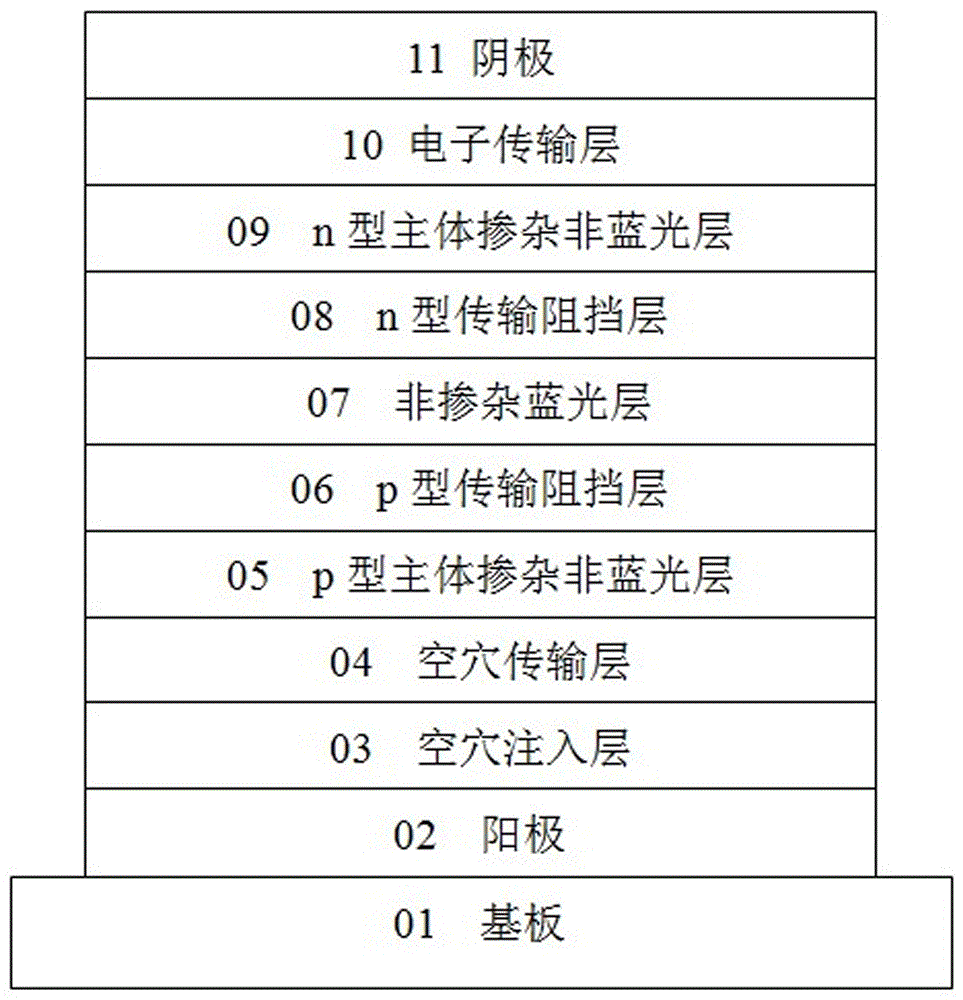

[0043] A white light organic electroluminescent device, such as figure 1 As shown, there are p-type body-doped non-blue light layer 05, p-type transmission blocking layer 06, non-doped blue light layer 07, n-type transmission blocking layer 08 and n-type body-doped non-blue light layer 09 in sequence from bottom to top , also provided with substrate 01, anode 02, hole injection layer 03, hole transport layer 04, electron transport layer 10 and cathode 11, substrate 01, anode 02, hole injection layer 03, hole transport layer 04, p-type The main body-doped non-blue light layer 05, the p-type transport blocking layer 06, the non-doped blue light layer 07, the n-type transport blocking layer 08 and the n-type main body-doped non-blue light layer 09, the electron transport layer 10 and the cathode 11 are arranged from bottom to top The order of the above stacks the settings one by one.

[0044] It should be noted that the layered structure of the white light organic electroluminesce...

Embodiment 2

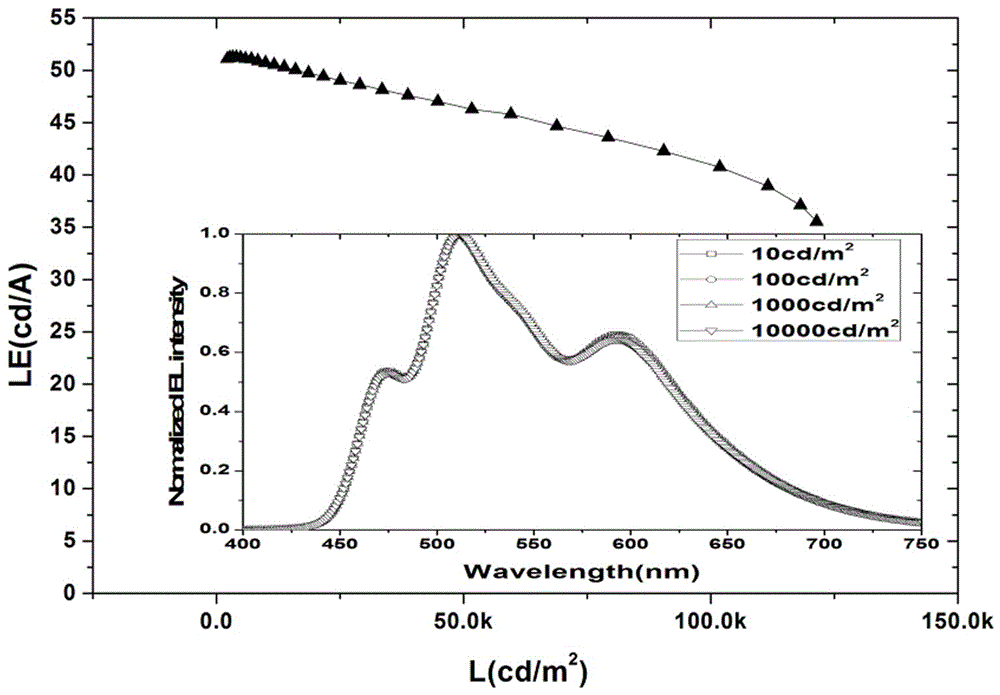

[0070] A white light organic electroluminescence device was prepared and its performance was tested.

[0071] Description of materials used:

[0073] HAT-CN: Dipyrazine [2,3- f :2',3'- h ]quinoxaline-2,3,6,7,10,11-hexamethancyanogen;

[0074] NPB: N,N'-di(naphthalene-1-yl)-N,N'diphenyl-benzidine;

[0075] Ir(MDQ) 2 (acac): (acetylacetonate) bis(2-methyldibenzo[F,H]quinoxaline) iridium;

[0076] TCTA: Tris(4-carbazol-9-yl-phenyl)amine;

[0077] Firpic: bis(3,5-difluoro-2-(2-pyridyl)phenyl-(2-carboxypyridine)iridium;

[0078] TPBi: 1,3,5-tris(1-phenyl-1H-benzimidazol-2-yl)benzene;

[0079] Ir(ppy) 3 : Tris(2-phenylpyridine) iridium;

[0080] Bepp 2 : Bis(2-(2-phenolyl)pyridine)beryllium.

[0081] In this embodiment, the adopted process flow is as follows: firstly, the commercial ITO glass is patterned, cleaned, and dried, and sent to the vacuum evaporation equipment; then the organic layers are prepared by vacuum thermal deposition; ...

Embodiment 3

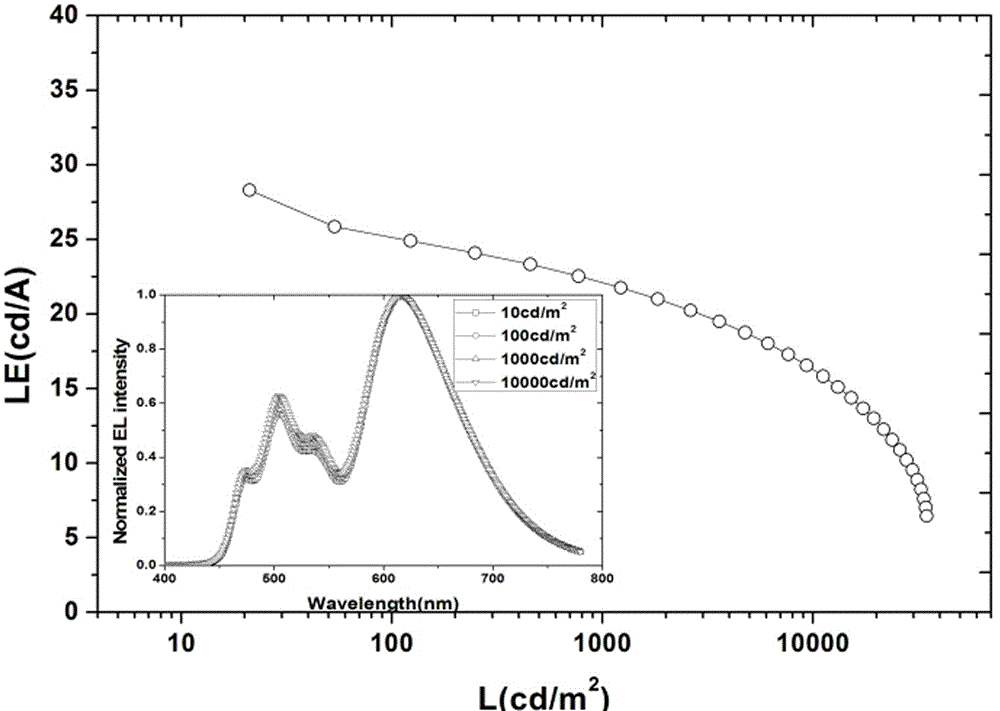

[0100] A white light organic electroluminescence device was prepared and its performance was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com