Method for ultra-smooth surface processing through ultraviolet-light-induced nano-particle colloid jet flow

An ultra-smooth surface and nano-particle technology, applied in the field of ultra-smooth surface processing, can solve the problems of low material removal efficiency, processing removal characteristics and uncontrollable factors of processing surface quality, and achieve the effect of improving efficiency and improving removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

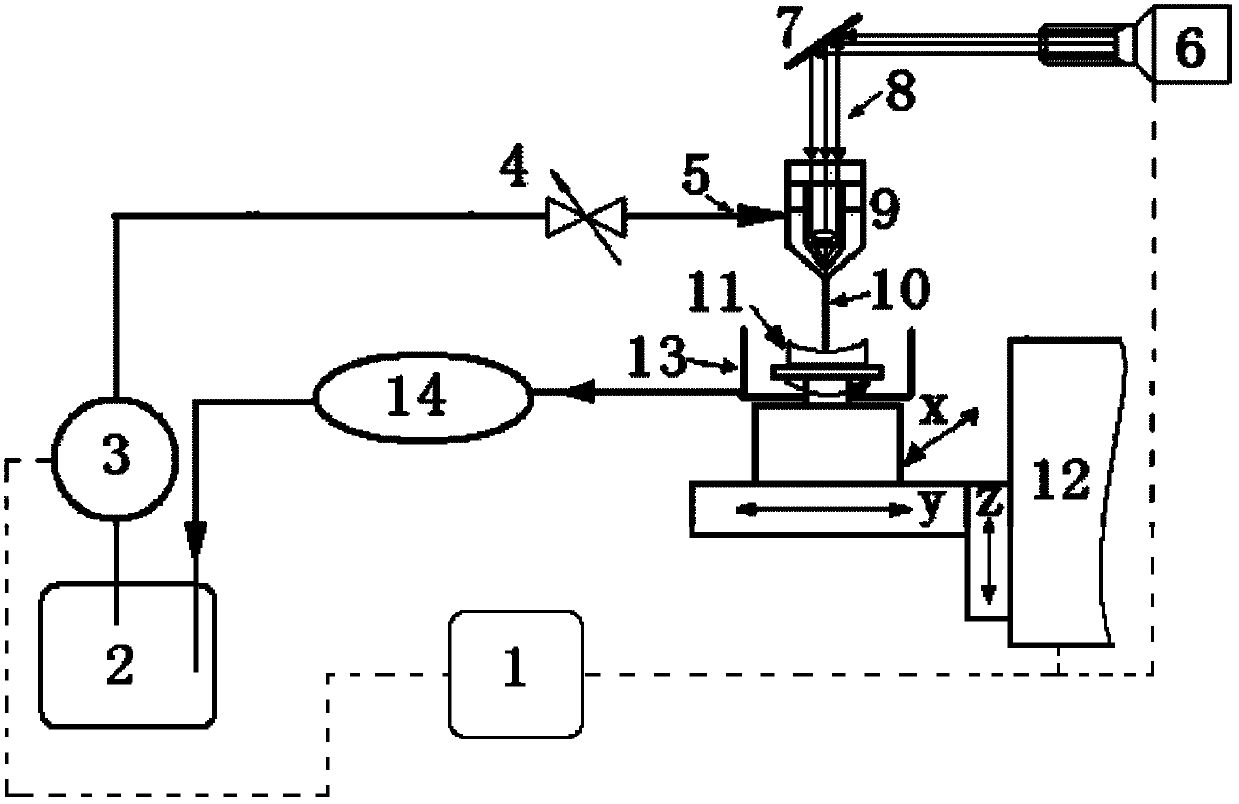

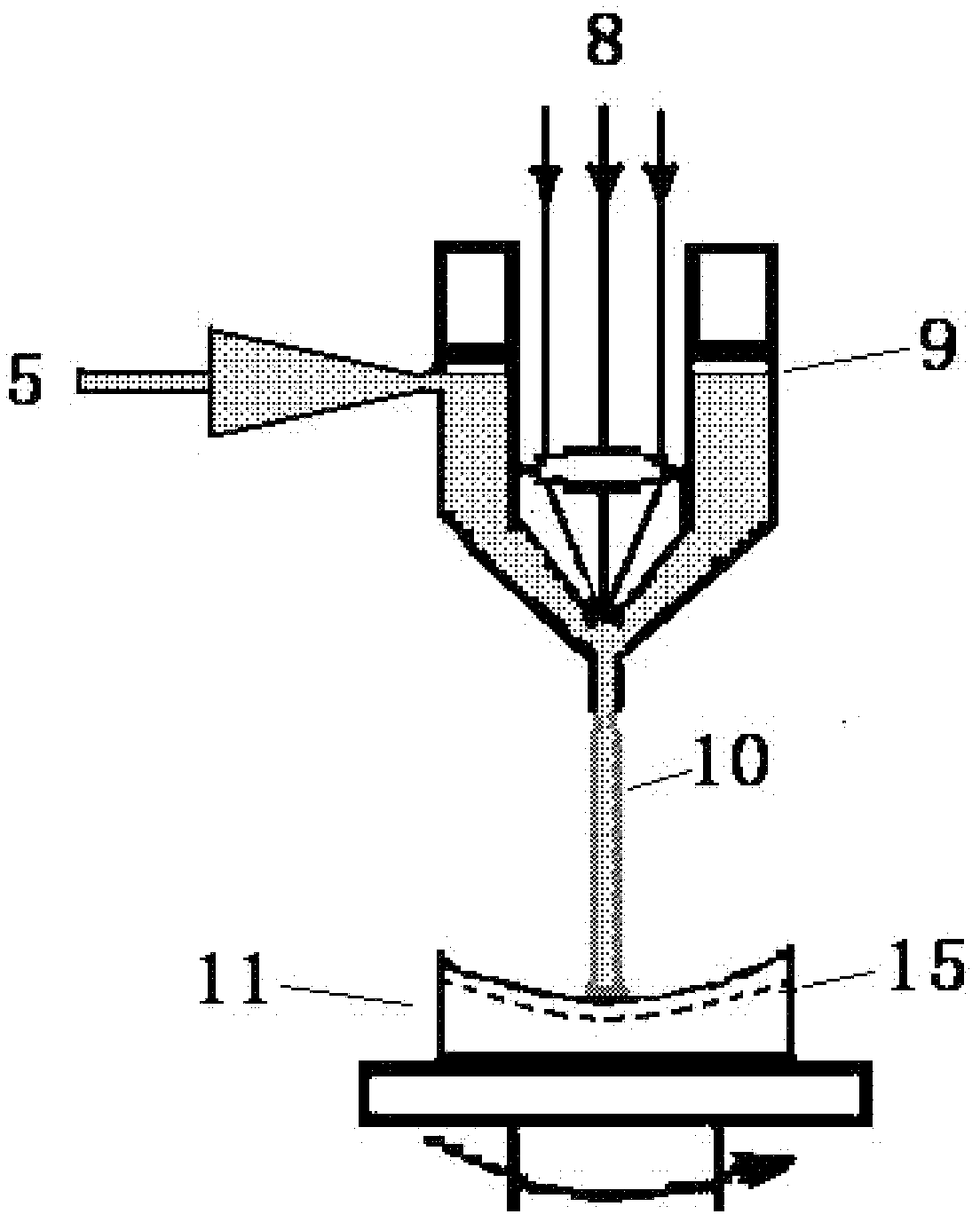

[0018] Specific implementation mode one: In this implementation mode, the ultra-smooth surface processing method induced by ultraviolet light colloidal jet flow of nanoparticles is as follows:

[0019] (1) Preparation of nanoparticle colloid:

[0020] In terms of mass percentage, 2.5% of titanium dioxide nanoparticles with a particle diameter of 20nm-30nm, 97% of deionized water, 0.15% of a pH regulator and 0.35% of a surfactant are used. Dosing according to these ingredients, using a mechanical dispersion method to disperse it for 20 minutes, to obtain a nanoparticle colloid with a pH value of 9;

[0021] (2) Nanoparticle colloidal pressure occurs:

[0022] The prepared titanium dioxide nanoparticle colloid is put into the nanoparticle colloid container 2, and then the nanoparticle colloid is generated with a pressure of 10 MPa by the booster device 3.

[0023] (3) Generation of focused ultraviolet beams:

[0024] Turn on the adjustable ultraviolet light source 6, wherein ...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the nanoparticle colloid consists of 5 parts by weight of nanoparticles, 94.5 parts of deionized water, 0.1 part of pH regulator, and 0.4 parts of active agent. into, wherein the particle size of the nanoparticles is below 50nm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the nanoparticle colloid consists of 8 parts by weight of nanoparticles, 91.5 parts of deionized water, 0.15 parts of pH regulator, and 0.35 parts of surfactant The composition of the agent, wherein the particle size of the nanoparticles is below 40nm, and the composition of the nanoparticles is a combination of 3 parts of nano-titanium dioxide particles and 5 parts of nano-cerium oxide particles. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com