Greenhouse crop culturing substrate and preparation method thereof

A cultivation substrate and greenhouse technology, applied in cultivation, preparation of organic fertilizers, treatment of bio-organic parts, etc., can solve problems such as environmental pollution, environmental pollution, difficulty in decomposition, etc., achieve less material consumption, eliminate infection routes, and reduce material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

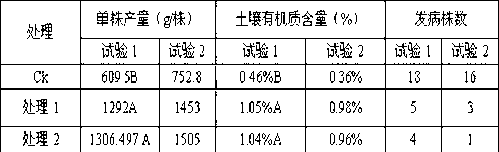

Examples

Embodiment 1

[0020] (1) First, cut the green corn stalks into 5cm small pieces, stack them in a trapezoidal shape, cover the top and surrounding areas with plastic film, press them tightly, and cover them firmly. Place a thermometer on the top of the trapezoidal pile to measure the temperature of the pile. The temperature of the pile body rose sharply to 65°C in the first 4 days, and then decreased. When the temperature of the pile body dropped to room temperature, the corn stalks were already decomposed.

[0021] (2) Fully mix fresh pig manure, quicklime and clay at a ratio of 12:1:1, stack them in a trapezoidal shape, and cover the top and surrounding areas with plastic film. And use a thermometer to measure the temperature of the pile body. When the temperature of the heap rises to 45°C, uncover the film, turn the heap, water until the water content of the heap reaches 80%, and cover the film. When the temperature of the heap reaches room temperature, it becomes decomposed pig manure. ...

Embodiment 2

[0029] (1) Grinding the decomposed corn stalks to a particle size of 0.5 cm;

[0030] (2) Crush the decomposed pig manure and pass it through a 5mm sieve.

[0031] (3) Mix and stack the decomposed corn stalks, pig manure and vinegar grains at a volume ratio of 3:3:4. Water thoroughly after mixing.

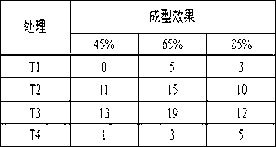

[0032] (4) When the relative water content of the heap is 65%, the mixed organic matter is taken out, pressed into a cube with a side length of 15cm, and on the top of the cube, dig a cylindrical hole with a diameter of 4cm and a height of 5cm; Then leave to dry.

[0033] (5) Place the pressed cultivation matrix cube on the cultivation bed, and then bury it to the middle of the cube with soil. Cucumbers were cultivated and managed in the greenhouse according to conventional management.

Embodiment 3

[0035] (1) crushing the decomposed corn stalks, the particle size of which is 5mm;

[0036] (2) Crush the decomposed pig manure and pass it through a 5mm sieve.

[0037] (3) Mix and stack the decomposed corn stalks, pig manure and vinegar grains in a volume ratio of 3.5:3:3.5. Water thoroughly after mixing.

[0038] (4) When the relative water content of the heap is measured to be 70%, the mixed organic matter is taken out and pressed into a cube with a side length of 15 cm. On the top of the cube, dig a small cylinder with a diameter of 4 cm and a height of 5 cm. hole; then set aside to dry.

[0039] (5) Place the pressed cultivation matrix cube on the cultivation bed, and then bury it to the middle of the cube with soil. Cucumbers were cultivated and managed in the greenhouse according to conventional management.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com