Preparation method of cyclohexanone-oxime

A technology of cyclohexanone oxime and cyclohexanone amidoxime is applied in the field of preparation of cyclohexanone oxime, and can solve the loss of titanium silicon molecular sieve, low cyclohexanone conversion rate and cyclohexanone oxime selectivity, catalyst pore volume and ratio The effect of avoiding the loss of titanium-silicon molecular sieve, high cyclohexanone oxime selectivity, and high cyclohexanone conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the cyclohexanone oxime according to the present invention comprises: under the cyclohexanone ammoximation reaction condition, make the reaction raw material that contains cyclohexanone, ammonia, hydrogen peroxide and solvent pass through the polyhedron in the fixed-bed reactor Each catalyst bed layer contains titanium silicate molecular sieve and resin, along the flow direction of the reaction raw material in the reactor, the content of the resin in the catalyst bed layer increases, and at least part of the catalyst The weight percentage of the resin in the bed layer is less than 50%.

[0016] According to a preferred embodiment of the present invention, along the flow direction of the reaction raw materials in the reactor, the total height of the catalyst bed with the weight percentage of the resin less than 50% is the total height of the catalyst bed. 5 to 90% of the height, more preferably 10 to 80%, even more preferably 20 to 60%.

[0017...

Embodiment 1

[0037] This example is used to illustrate the preparation method of the cyclohexanone oxime of the present invention.

[0038] (1) Preparation of composite catalyst

[0039] In the polymerization reactor, add Ti-MWW molecular sieve powder, styrene, divinylbenzene and gasoline, stir and mix evenly, when the water bath is heated to 60°C, add benzoyl peroxide, and react at 90°C for 6 hours to obtain The block composite catalyst is then crushed to obtain composite catalyst particles with a particle size of 1-3 mm, then added to 250 milliliters of 1,2-dichloroethane to swell, keep swelling for 5 hours at normal temperature, and then pour out 1 , 2-dichloroethane, and then add 200 ml of ethyl acetate for solvent extraction, the extraction temperature is 55 ° C, the extraction time is 4 hours, and the extraction is repeated three times to obtain a composite catalyst of titanium silicon molecular sieve and resin.

[0040] Composite catalysts A1-A3 of titanium-silicon molecular sieves...

Embodiment 2

[0061] This example is used to illustrate the preparation method of the cyclohexanone oxime of the present invention.

[0062] (1) Preparation of composite catalyst

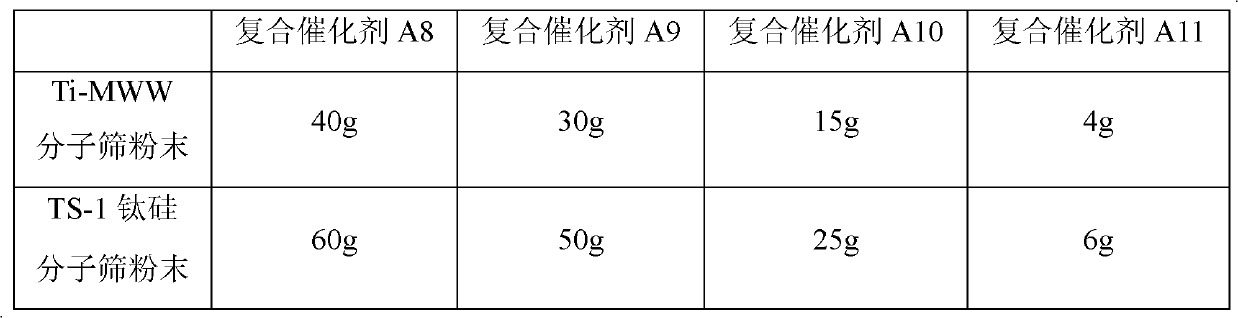

[0063] In the polymerization reactor, add Ti-MWW molecular sieve powder, TS-1 titanium silicon molecular sieve powder, styrene, divinylbenzene and amyl alcohol, stir and mix evenly, when the water bath is heated to 60°C, add azobisisobutanol , reacted at 100°C for 6 hours to obtain a block composite catalyst, and then crushed to obtain composite catalyst particles with a particle size of 1-3 mm, and then added 250 ml of 1,2-dichloroethane to swell. Keep swelling for 5 hours, then pour out 1,2-dichloroethane, then add 200 milliliters of xylene to carry out solvent extraction, the extraction temperature is 55 ° C, the extraction time is 4 hours, and the extraction is repeated three times to obtain Composite catalyst of titanium silicate molecular sieve and resin.

[0064] Composite catalysts A4-A7 of titanium-sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Conversion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com