Synthetic method of 2-thiophene ethylamine

一种噻吩乙胺、合成方法的技术,应用在有机化学等方向,能够解决苯磺酰氯污染严重、难再生利用、氨易挥发等问题,达到容易回收、简化操作、环境污染小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

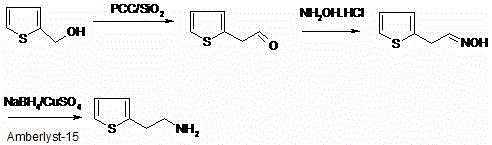

[0029] Implement a kind of synthetic method of 2-thienylethylamine, and its described method is carried out according to the following steps:

[0030] 1) PCC / SiO2 2 Preparation of oxidizing agent

[0031] Under stirring, 20g (0.2mol) CrO 3 Add it to 38.8mL (6mol / L) hydrochloric acid, cool the homogeneous system to 0°C after 5min, slowly add 15.8g (0.2mol) pyridine dropwise, and precipitate occurs. After adding, continue to react for 1h and filter. Add 140mL of water to the filter cake until the solids are completely dissolved, add 100g of macroporous silica gel (pore size 400-500?) at 50°C and impregnate for 24h. Vacuum drying for 24 h yielded 143 g of product.

[0032] 2) Preparation of 2-thiopheneacetaldehyde

[0033] 143g PCC / SiO 2 1. Add 500mL of n-hexane into the reaction flask, heat to 50°C, and slowly drop in a solution consisting of 12.8g of 2-thiophenethanol and 30mL of n-hexane. After dropping, it was detected by TLC until the conversion of the reaction r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com