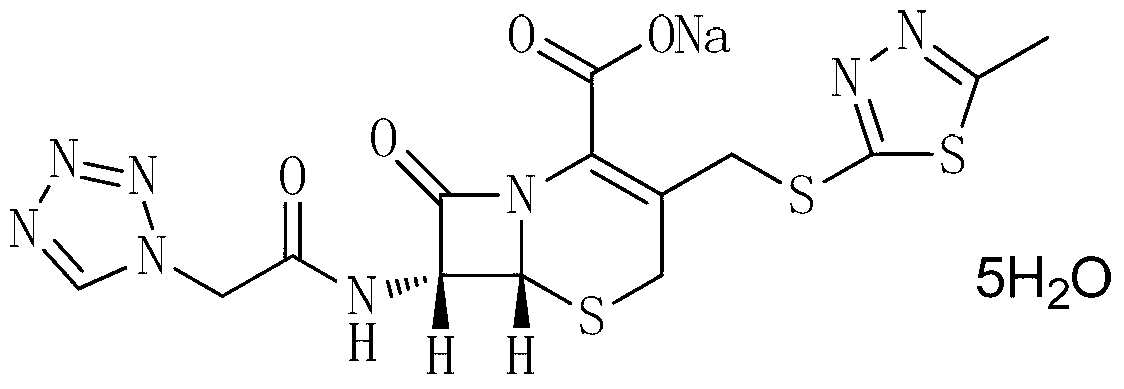

Cefazolin sodium pentahydrate compound and preparation method and medicine composition thereof

A technology of cefazolin sodium and compound, applied in the field of medicine, can solve problems such as poor stability of cefazolin sodium pentahydrate, and achieve the effects of less impurity content, high safety performance and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of cefazolin sodium pentahydrate compound

[0039] Dissolve cefazolin sodium pentahydrate in N,N-dimethylformamide, slowly add water at 40°C under stirring condition, the volume of said N,N-dimethylformamide is equal to that of cefazolin sodium pentahydrate The mass ratio of N,N-dimethylformamide to water is 1ml:35mg, the volume ratio of N,N-dimethylformamide to water is 3:1, adjust to pH 5.0, stir for 35 minutes to obtain a clear liquid medicine, and move the liquid medicine into the reaction kettle , put it at 130°C for 24 hours, take it out, let it stand, and cool it down to 60°C at a rate of 10°C / min, open the kettle, add ethanol dropwise, and stir, the volume of ethanol is 5 times the volume of the liquid medicine , After the dropwise addition, cool to 0°C, filter, wash twice with ethanol, then wash twice with water, and then dry under reduced pressure for 2h to obtain. Yield 64.4%, HPLC content 99.79%. mp: 238-242°C.

Embodiment 2

[0042] Preparation of cefazolin sodium pentahydrate compound

[0043]Dissolve cefazolin sodium pentahydrate in N,N-dimethylformamide, slowly add water at 50°C under stirring condition, the volume of said N,N-dimethylformamide is equal to that of cefazolin sodium pentahydrate The mass ratio of N,N-dimethylformamide to water is 1ml:50mg, the volume ratio of N,N-dimethylformamide to water is 2:1, adjust to pH5.5, stir for 25min to obtain a clear liquid, and move the liquid into the reaction kettle , put it at 150°C for 48 hours, take it out, let it stand, and cool it down to 70°C at a rate of 5°C / min, open the kettle, add ethanol dropwise, and stir, the volume of ethanol is 8 times the volume of the liquid medicine , After the dropwise addition, cool to 5°C, filter, wash twice with ethanol, then wash twice with water, and then dry under reduced pressure for 4h to obtain. Yield 65.5%, HPLC content 99.80%. mp: 238-242°C.

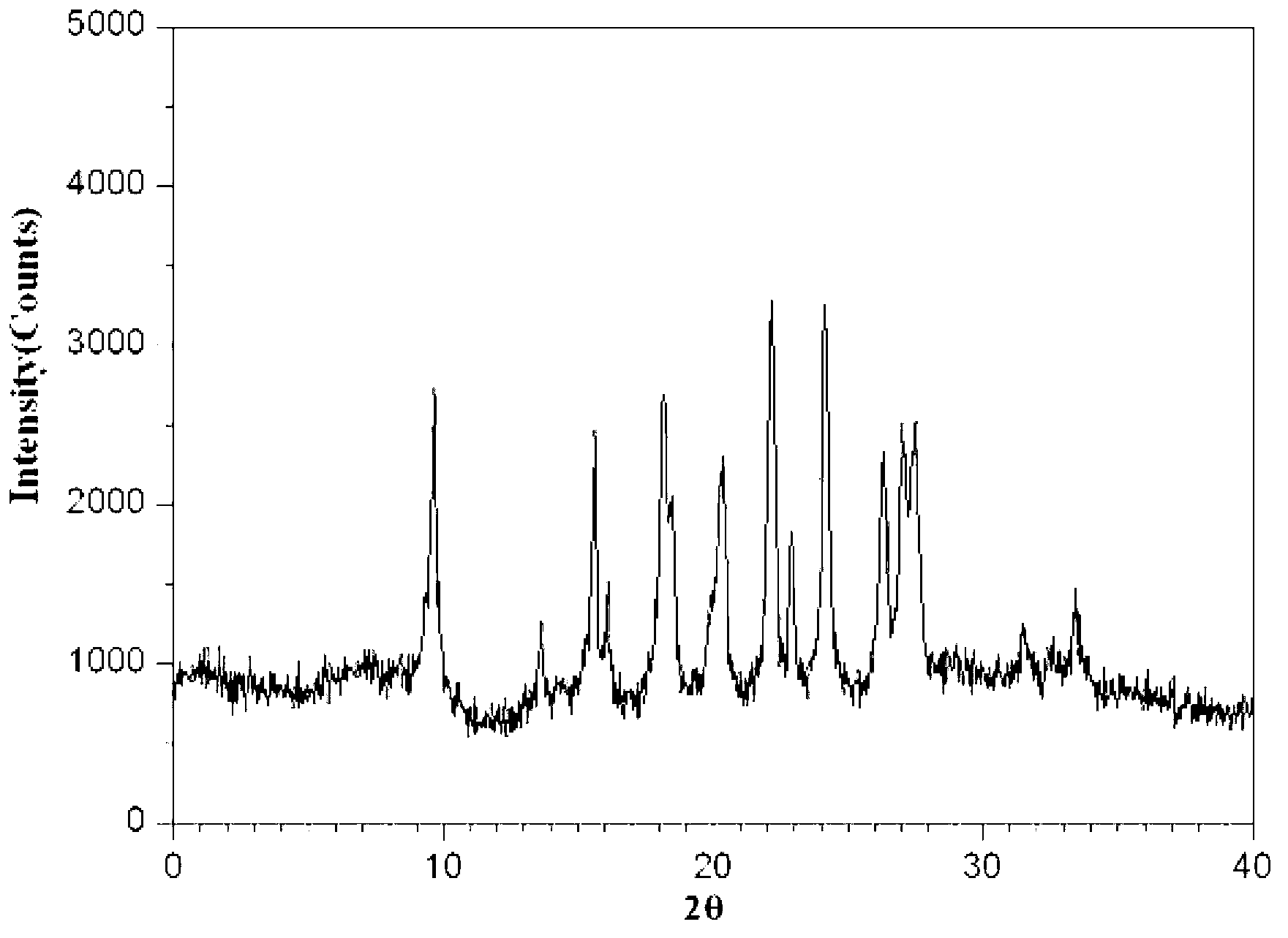

[0044] The X-ray powder diffraction pattern obtained by ...

Embodiment 3

[0046] Preparation of Cefazolin Sodium Pentahydrate Sterile Powder Injection

[0047] Weigh 999 g of cefazolin sodium pentahydrate and 1 g of sodium benzoate prepared in Example 1 under aseptic conditions, place them in a solid powder mixer and mix them uniformly, and the raw materials obtained are transferred to a sterile preparation workshop for precision metering and subpackaging, each bottle Contains vinpocetine 0.25g, stoppered and capped, and the finished product is packaged for storage and sent for inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com