A preparation method of ultraviolet detector based on fluorescent coating integrating sphere

A technology of ultraviolet detector and fluorescent coating, which is applied in the field of ultraviolet detection, can solve the problems of poor sensitivity, affecting device sensitivity, poor resolution and response non-uniformity, and achieve good effect, convenient and accurate detection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The ultraviolet detector based on the fluorescent coating integrating sphere is a silicon-based detector that uses the integrating sphere as a collector of signal light and responds to visible light. The preparation method steps are as follows:

[0015] 1) The integrating sphere is made of metal or plastic material, and the inner surface is polished to ensure the firm adhesion between the surface of the sphere and the film layer;

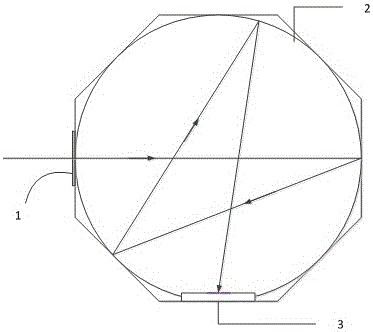

[0016] 2) if figure 1 As shown in the schematic diagram, the sphere is divided into two hemispheres, and semicircular holes of the same radius are respectively opened on the round sides of the two integrating hemispheres, and the inner wall of the integrating sphere is uniformly coated by vacuum or spin coating 2; in order to ensure the uniformity of the film layer, The hemisphere is rotated at a constant speed during true coating; the coating material used is a fluorescent material with ultraviolet excitation and emission characteristics, s...

Embodiment

[0021] Embodiment: adopt light metal aluminum to make a 6-inch sphere, the sphere is divided into 2 hemispheres; Adopt special chemical reagent to polish the inner surface; Open semicircular holes with the same radius on the round edges of the two integral hemispheres, merged as The entrance light hole; adopt the coating method of vacuum thermal evaporation to deposit a layer of Lumogen fluorescent film on the inner wall of the integrating sphere; the sphere is assembled into a complete sphere by mechanical fastening method, and the bottom of the integrating sphere is in a 90° direction with the entrance hole A rectangular hole is opened on the top, and a linear array CCD of model ILX55B is fixed, and a fixing bracket is installed outside the sphere to make an ultraviolet detector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com