Graphite intercalation compound lithium-ion battery negative electrode material, as well as preparation method and application thereof

A lithium-ion battery and graphite intercalation technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low reversible capacity and small interlayer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

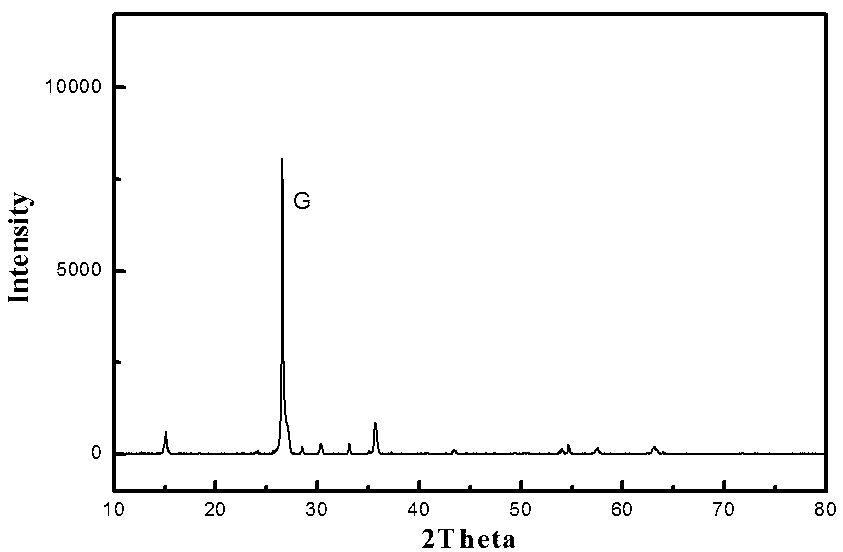

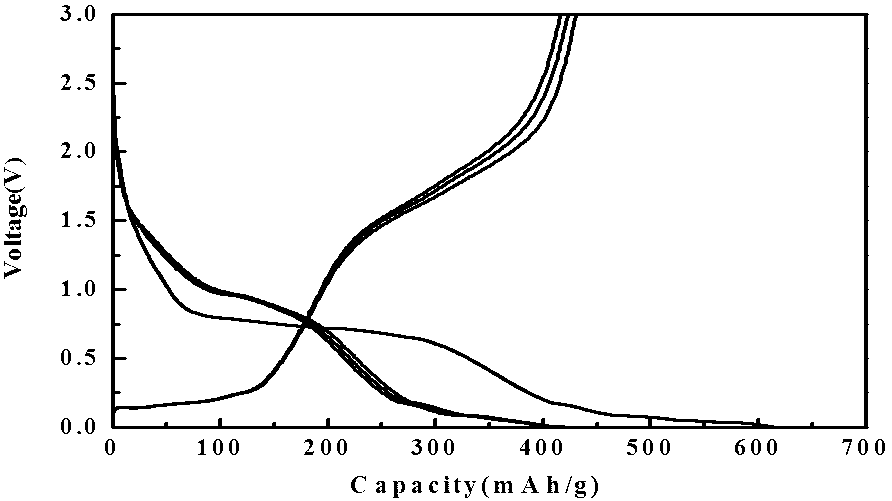

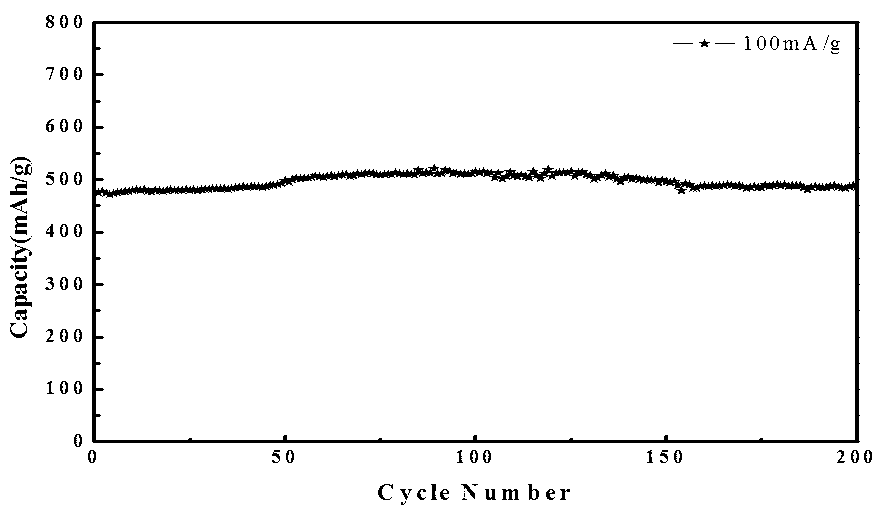

Image

Examples

Embodiment 1

[0046] Weigh 2g of graphite and 5.41g of anhydrous ferric chloride (the molar ratio of graphite to ferric chloride is 10:2) and mix them thoroughly, and then dry them in a vacuum oven at 80°C for 8 hours. The dried sample is treated at 600°C in a nitrogen atmosphere 3 hours. The resulting product is washed with deionized water until there is no Fe in the washing liquid 3+ . The washed sample was dried in a vacuum oven at 120°C for 10 hours.

[0047] The negative electrode material powder prepared above and the 9% polyvinylidene fluoride N-methyl-2-pyrrolidone solution are fully ground into a uniform slurry-like viscous liquid, wherein the polyvinylidene fluoride accounts for 10% of the weight of the negative electrode material powder; The copper foil is coated with a thickness of 0.1mm, and the solvent is volatilized and subjected to rolling treatment under a pressure of 1MPa, and then placed in a vacuum oven at 80°C for 12 hours to dry, which is used as a working electrode of a...

Embodiment 2

[0049] Weigh 2g of graphite and 4.33g of anhydrous cobalt chloride (the molar ratio of graphite to cobalt chloride is 10:2) and mix them thoroughly, and then dry them in a vacuum oven at 80°C for 8 hours. The dried sample is treated at 700°C in a nitrogen atmosphere. 3 Hours. The resulting product is washed with deionized water until there is no Co in the washing liquid 3+ . The washed sample was dried in a vacuum oven at 120°C for 10 hours.

[0050] The negative electrode material powder prepared above and the 9% polyvinylidene fluoride N-methyl-2-pyrrolidone solution are fully ground into a uniform slurry-like viscous liquid, wherein the polyvinylidene fluoride accounts for 10% of the weight of the negative electrode material powder; The copper foil is coated with a thickness of 0.1mm, and the solvent is volatilized and subjected to rolling treatment under a pressure of 1MPa, and then placed in a vacuum oven at 80°C for 12 hours to dry, which is used as a working electrode of ...

Embodiment 3

[0052] Weigh 2g of graphite and 4.48g of anhydrous copper chloride (the molar ratio of graphite to copper chloride is 10:2) and mix them thoroughly, and then dry them in a vacuum oven at 80°C for 8 hours. The dried sample is treated at 500°C in a nitrogen atmosphere. 3 Hours. The resulting product is washed with deionized water until there is no Cu in the washing liquid 2+ . The washed sample was dried in a vacuum oven at 120°C for 10 hours.

[0053] The negative electrode material powder prepared above and the 9% polyvinylidene fluoride N-methyl-2-pyrrolidone solution are fully ground into a uniform slurry-like viscous liquid, wherein the polyvinylidene fluoride accounts for 10% of the weight of the negative electrode material powder; The copper foil is coated with a thickness of 0.1mm, and the solvent is volatilized and subjected to rolling treatment under a pressure of 1MPa, and then placed in a vacuum oven at 80°C for 12 hours to dry, which is used as a working electrode of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge capacity | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com