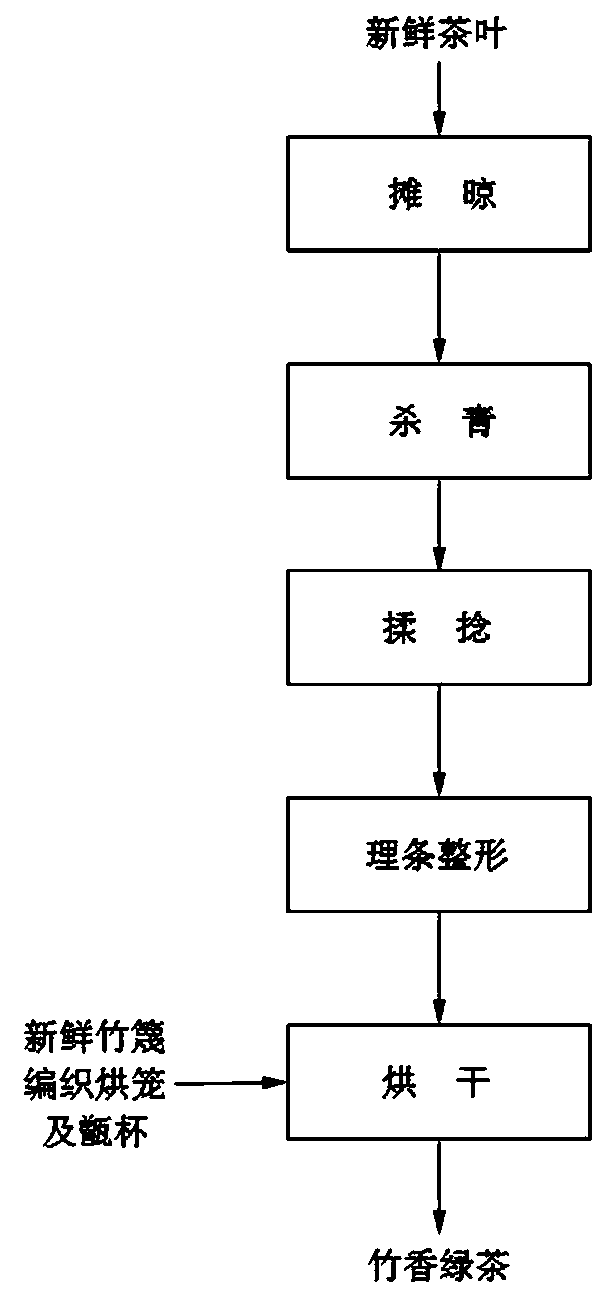

A kind of processing method of bamboo fragrance green tea

A processing method and technology for bamboo-flavored green tea, applied in the directions of tea spice, tea treatment before extraction, etc., can solve the problems of cumbersome, light fragrance, light fragrance, etc., and achieve the effects of reducing production cost, strong fragrance, and unique bamboo fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take the fresh and tender single buds of the large-leaf species produced in Yunnan and spread them in a cool and ventilated place for 5 hours, so that the water content of the fresh leaves will be lost to 70%. Finish in the green-fixing roller for 110 seconds; knead the finished tea leaves for 12 minutes by means of air pressure-light pressure-air pressure until more than 95% of the tea leaves are formed into strips, and the hands feel wet and sticky. 2.5kg of tea leaves after kneading are placed in a slitting machine with a hot air temperature of 120°C for 15 minutes to obtain tea leaves with a moisture content of 16%; the bamboo charcoal in the stove is set on fire, fully burned until there is no smoke and no open flame, Ash cover the burning charcoal completely, then place 2kg of tea leaves in a cylindrical oven with a diameter of 60cm and a height of 60cm, place it on a retort cup 30cm from the bottom of the oven, and put the oven on the stove Heat the bottom and ke...

Embodiment 2

[0029] Take one bud and one leaf of the large-leaf species produced in Yunnan and spread them in a cool and ventilated place for 4 hours, so that the water content of the fresh leaves will be lost to 75%; then put about 0.6kg of tea leaves after spreading and drying in a drum with a wall temperature of 340°C Medium-cooking for 100s; Knead the finished tea with air pressure-light pressure-air pressure for 10 minutes until more than 90% of the tea leaves are in strips, and the hand feels wet and sticky, and the Haofeng appears; Knead The final 2.7kg of tea leaves were placed in a slitting machine with a hot air temperature of 100°C for 16 minutes to obtain tea leaves with a moisture content of 18%; the chestnut charcoal in the stove was ignited and fully burned until there was no smoke and no open flames, and the The burning chestnut charcoal is completely covered, and then 3kg of well-organized tea leaves are placed in a cylindrical oven with a diameter of 100cm and a height of ...

Embodiment 3

[0031]Take one bud and two leaves of the small-leaf species produced in Yunnan and spread them in a cool and ventilated place for 6 hours, so that the water content of the fresh leaves will be lost to 80%; then put about 0.5kg of tea leaves after spreading and drying in a drum with a wall temperature of 320°C Finishing for 120s; knead the finished tea leaves for 15 minutes by means of air pressure-light pressure-pneumatic pressure until more than 92% of the tea leaves are formed into strips, and the hand feels wet and sticky, and the Haofeng appears; after kneading 3kg of tea leaves were placed in a rafting machine with a hot air temperature of 110°C for 18 minutes to obtain tea leaves with a moisture content of 20%; the pine wood charcoal in the stove was set on fire and fully burned until there was no smoke and no open flame, and the burning The pine charcoal is completely covered, and then 1.5kg of well-organized tea leaves are placed in a cylindrical oven with a diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com