Method for preparing hydrotalcite like compound/attapulgite composite material

A composite material and hydrotalcite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as poor regeneration performance, limited adsorption capacity, incomplete adsorption, etc., and achieve good treatment effect , good regeneration performance, and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The present invention is the preparation method of hydrotalcite-like / attapulgite composite material, and its steps are:

[0016] (1) Add attapulgite clay to distilled water, stir and disperse for 0.5 hours, and prepare a 0.01-0.03% suspension solution;

[0017] (2) Add surfactant, magnesium nitrate and aluminum nitrate in turn, and stir for 0.5h;

[0018] (3) Slowly add the mixed solution containing alkali and sodium carbonate dropwise during stirring, and continue stirring for 1 hour after the dropwise addition is completed;

[0019] (4) After the stirring is completed, let it stand for aging for 1 hour;

[0020] (5) Suction filter until neutral, and dry at 60°C to obtain a finished white composite material.

[0021] The attapulgite clay used above is pure soil. The alkali molar ratio of the above mixed solution is 0.1-0.6 mol / L. Described alkali is sodium hydroxide, or ammonia water. Described surfactant is dodecylbenzenesulfonic acid, or silane coupling agent. ...

Embodiment 1

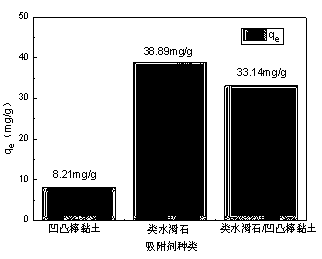

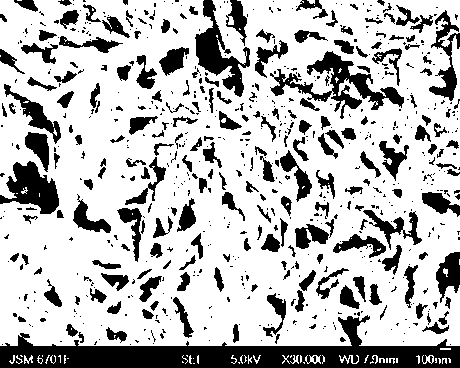

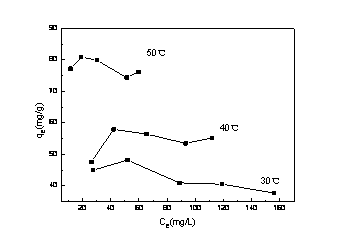

[0023] Example 1: Weigh 3.0g of attapulgite clay, put it into a 500mL three-neck bottle, add 200mL of water and stir evenly to form a suspension, add 2.0ml of silane coupling agent KH570, 6.4g of magnesium nitrate, and 3.75g of nitric acid in sequence Aluminum, stirred for 0.5h, slowly added dropwise 20mL of a mixed solution containing 2.4g sodium hydroxide and 5.3g sodium carbonate during the stirring, continued to stir for 1h after the dropwise addition was completed, stood for aging for 1h after the stirring was completed, and filtered until neutral, 60 ℃ drying to obtain the finished white composite material. Such as figure 1 Shown is the comparison of the adsorption capacity of the composite material, pure hydrotalcite-like and attapulgite clay. figure 2 Scanned pictures for electron microscopy of composite materials. Such as image 3 As shown, the composite material has an adsorption capacity of 33.14mg / g for Ni(Ⅱ) at pH=6.0.

Embodiment 2

[0024] Example 2: Weigh 3.0g of attapulgite clay, put it into a 500mL three-necked bottle, add 200mL of water and stir evenly to form a suspension, and add 0.5ml of silane coupling agent KH570, 0.64g of magnesium nitrate, and 0.375g of nitric acid to the suspension in sequence Aluminum, stirred for 0.5h, slowly added dropwise 20mL of a mixed solution containing 1.0g sodium hydroxide and 0.53g sodium carbonate during the stirring, continued to stir for 1h after the dropwise addition was completed, stood for aging for 1h after the stirring was completed, and suction filtered until neutral, 60 ℃ drying to obtain the finished white composite material. Such as image 3 As shown, the composite material has an adsorption capacity of 27.26mg / g for Ni(Ⅱ) at pH=6.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com