A kind of glue for firework and firecracker paper lead wire and preparation method thereof

A firecracker paper and hair paper lead wire technology, which is applied in the field of fireworks and firecrackers, can solve the problems of being affected by cloudy and rainy days, long air-drying time, and large drug stagnation, so as to achieve no powder and drug leakage, clean and dry surface, and reduce The effect of stagnant dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Glue for fireworks paper leads

[0021] formula:

[0022] Nitrocellulose 80kg

[0023] Phenolic resin 25kg

[0024] Double base pipe 50kg

[0025] Anhydrous methanol or ethanol 1000kg

[0026] Preparation Process:

[0027] Dissolve the formulated amount of nitrocellulose and phenolic resin with anhydrous methanol or ethanol, stir, then add the double-base tube, stir evenly, and form a uniform solution to obtain glue.

Embodiment 2~6

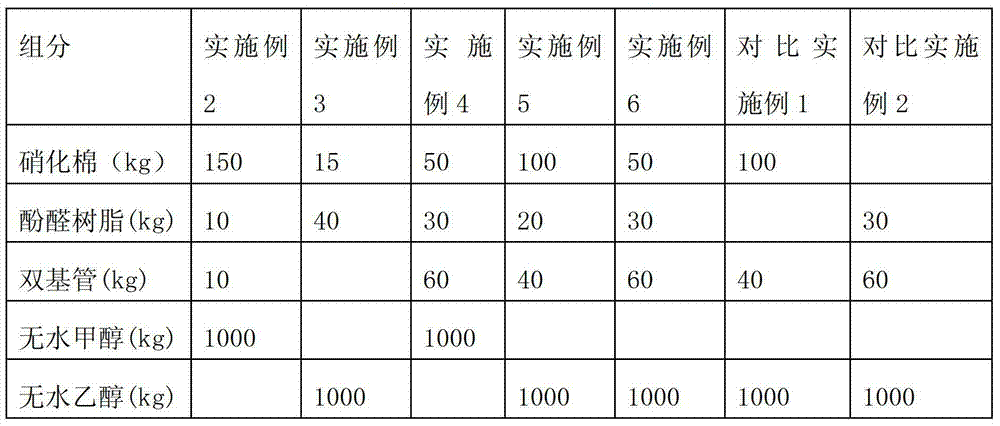

[0029] Glue formula see table 1 below

[0030] Table 1 Glue recipe for fireworks paper leads:

[0031]

[0032] The preparation method is the same as the preparation process of Example 1 (wherein, the unit can also be parts by weight).

Embodiment 7

[0034] Preparation of Paper Leads for Fireworks and Firecrackers

[0035] 1) Twist the lead paper and the lead medicine into wool paper lead wires,

[0036] 2) Pass the semi-finished paper lead through or coat the glue obtained in Examples 1-6;

[0037] 3) Air-dry for 1-2 hours, remove methanol or ethanol, and obtain paper leads.

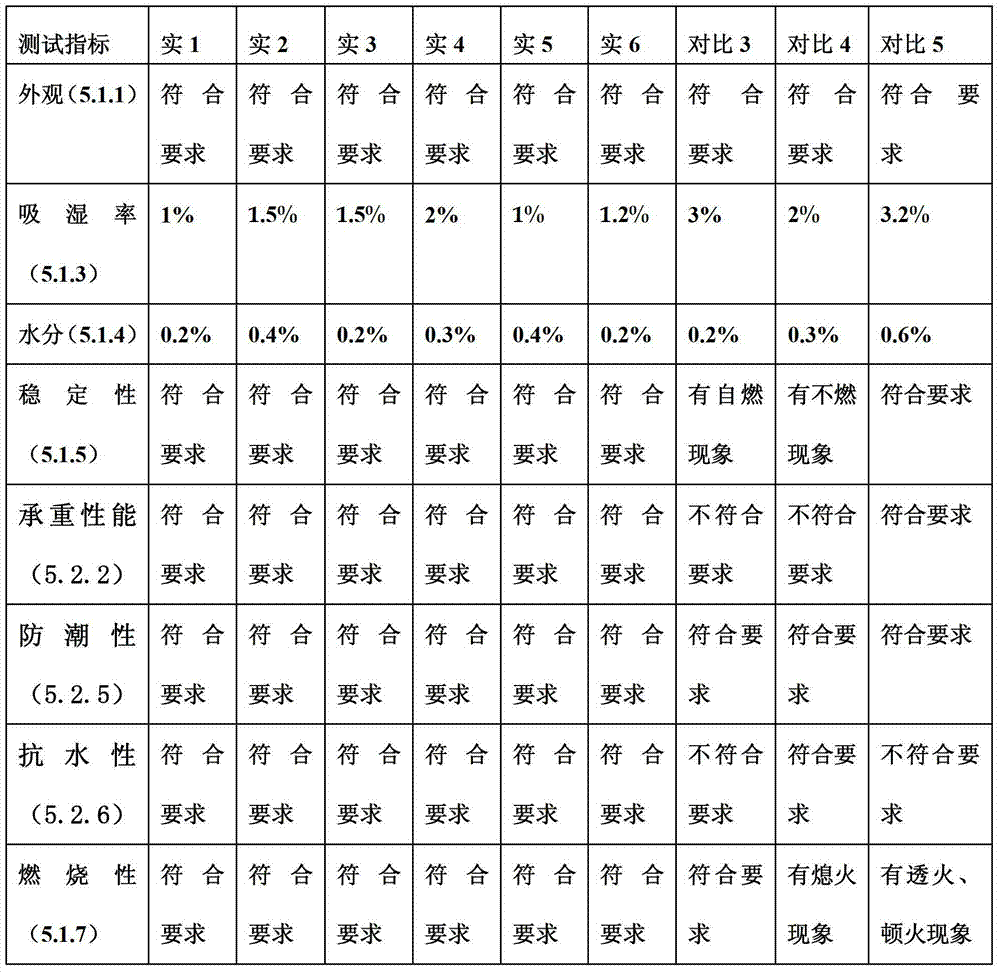

[0038] In embodiment 7, the paper leads drawn by the glue slurry obtained in Examples 1 to 6 are respectively referred to as embodiment 1 paper leads, referred to as "real 1", embodiment 2 paper leads, referred to as "real 2", and embodiment 3 paper leads. Lead, be called for short " real 3 ",, embodiment 4 paper lead, be called for short " real 4 ", embodiment 5 paper lead, be called for short " real 5 ", embodiment 6 paper lead, be called for short " real 6 ".

[0039] According to the indicators in Article 5 and the test method in Article 6 of the national standard GB195952004, test the paper leads of 1 to 6, and the test results all meet the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com