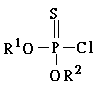

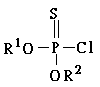

Waste residue-free preparation method of O,O-dialkyl thiophosphoryl chloride

A technology of alkyl phosphorothioate and dialkyl phosphorodithioate, which is applied in the field of waste-free preparation of O,O-dialkyl phosphorothioate chloride, which can solve the problem of difficult to handle viscous sulfur waste residue and large reaction heat generation , low product content and other problems, to achieve the effect of easy industrial transformation, high yield and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

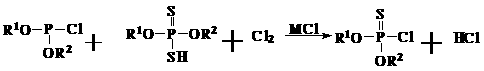

Method used

Image

Examples

Embodiment 1

[0025] In a 1000ml four-neck flask with an air duct, a cooling device, and a thermometer, 310g of diethyl chlorophosphite, 372g of O, O-diethyl phosphorodithioate, and 2g of aluminum chloride were successively put in; Slowly raise the temperature to 35°C, feed 164g of chlorine gas within 4 hours, keep it warm for 4 hours, use nitrogen to drive away the excess chlorine and hydrogen chloride gas; stir intermittently, quickly cool down to 25°C; filter at 25°C to obtain O,O- Diethyl thiophosphoryl chloride 735g, the content is 98%; Calculated with diethyl chlorophosphite, the yield is 96%.

Embodiment 2

[0027] In a 1000ml four-neck flask with an air duct, a cooling device, and a thermometer, 310g of diethyl chlorophosphite, 372g of O, O-diethyl phosphorodithioate, and 2g of aluminum chloride were successively put in; Slowly raise the temperature to 35°C, feed 164g of chlorine gas within 4 hours, keep it warm for 4 hours, use nitrogen to drive away the excess chlorine and hydrogen chloride gas; cool down to 25°C; filter at 25°C, wash the filtrate with water, and separate to obtain O,O -Diethylphosphorylthiochloride 715g, content is 99.5%; Calculated yield is 95% with diethyl chlorophosphite.

Embodiment 3

[0029] Into a 1000ml four-neck flask with air duct, cooling device and thermometer, put 310g of diethyl chlorophosphite, 372g of O,O-diethyl phosphorodithioate and 0.5g of aluminum chloride in sequence. and the last batch of filter residue 2.5g; slowly warm up to 35°C, feed 164g of chlorine gas within 4 hours, keep warm for 4 hours, use nitrogen to drive away the excess chlorine and hydrogen chloride gas; intermittently stir, quickly cool down to 25°C; at 25°C O, O-diethylphosphorothiochloride 735g was obtained by filtration at a lower temperature, with a content of 98%; the yield was 96% based on diethyl chlorophosphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com