Thin-film pressure sensor adopting titanium oxynitride as strain material and manufacturing method thereof

A technology of titanium oxynitride and strain materials, which is applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve problems such as thermal stability of pressure sensors, and achieves easy mass production, simplified process steps, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

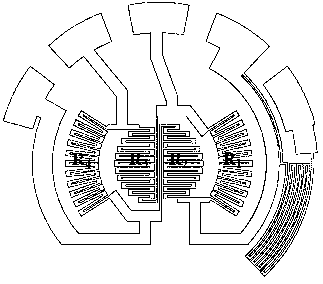

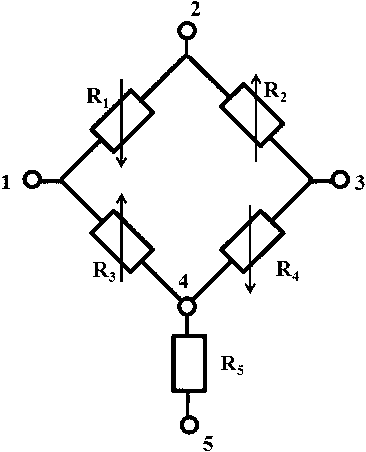

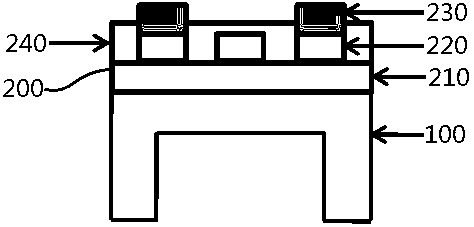

[0032] Such as figure 1 As shown, the thin film pressure sensor using titanium oxynitride as the strain material of the present invention includes a stainless steel elastic substrate 100, on which a core film layer 200 is arranged on the stainless steel elastic substrate 100, and the core film layer 200 includes an insulating Layer 210, strain resistance layer 220, electrode and temperature measuring resistance layer 230 and passivation layer 240, the insulating layer 210, strain resistance layer 220, electrode and temperature measuring resistance layer 230 and passivation layer 240 are successively passed through the method of vacuum deposition deposited on the stainless steel elastic substrate 100.

[0033] In the present invention, the strai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com